Pressure roller adjustment – Grizzly G0716 User Manual

Page 38

-36-

Model G0716 (Mfg. Since 2/11)

pressure Roller

Adjustment

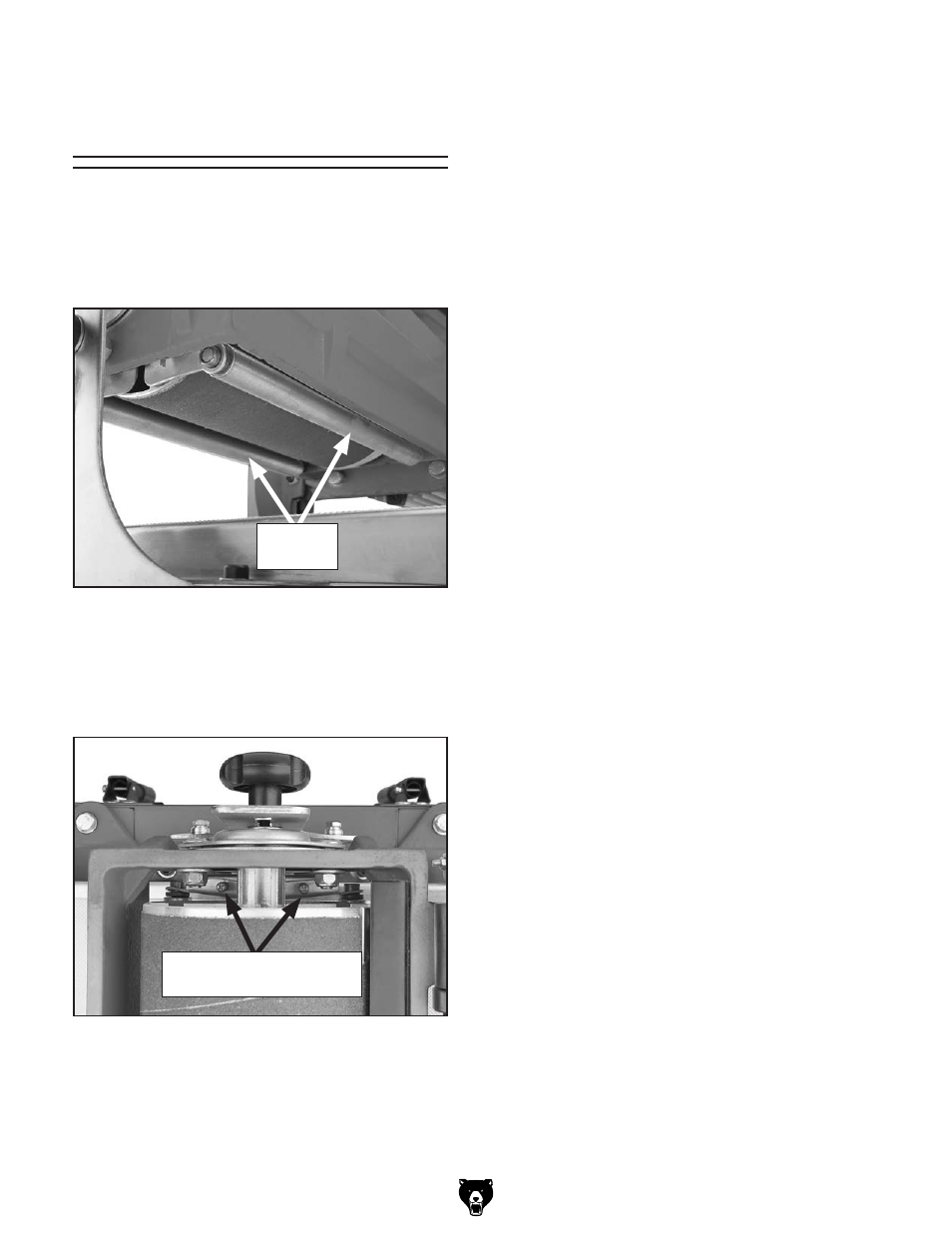

the height of the pressure rollers (see

figure 36)

is set slightly below the bottom of the sanding

drum to keep the workpiece firmly against the

conveyor belt as it passes through the sander,

preventing workpiece kickback.

figure 36. location of the pressure rollers.

pressure

rollers

proper pressure on the workpiece helps avoid

kickback and keeps the workpiece from slipping.

however, as pressure increases on the workpiece

from the rear pressure roller, snipe also increases.

in this case, decrease the pressure on the rear

roller.

if you choose to increase or decrease the pres-

sure that these rollers exert on the workpiece,

perform the following procedure.

tool Needed

Qty

hex Wrench 5mm .............................................. 1

phillips screwdriver #2 ...................................... 1

to adjust the pressure rollers:

1. disCoNNECt saNdEr FroM poWEr!

2. remove the cap screw that secures the dust

collection hood, then lift the hood up to gain

access to the pressure roller adjustment

screws.

3. to increase the pressure exerted by the roll-

ers, tighten all four screws in small, equal

amounts, then test the pressure of the rollers

by pressing up on them.

Conversely, loosen the adjustment screws to

lessen the pressure.

4. test your adjustments by sanding a scrap

workpiece.

— if the workpiece tends to kickback, reduce

the pressure by rotating the screws coun-

terclockwise one turn, then perform the test

again.

— if the workpiece slips on the conveyor

belt, increase the pressure by rotating the

screws clockwise one turn, then perform

the test again.

the pressure these rollers exert on the workpiece

as it passes underneath the sanding head is con-

trolled by compression springs and adjustment

screws (see

figure 37).

figure 37. location of the pressure roller

adjustment screws.

pressure adjustment

screws (one side shown)