Feed rate, Notice, Sanding tips – Grizzly G0716 User Manual

Page 28

-26-

Model G0716 (Mfg. Since 2/11)

feed Rate

setting the proper feed rate is a matter of experi-

ence and good judgement. When selecting the

feed rate for the operation, consider variables

such as the hardness and condition of the wood,

the sandpaper grit being used, the finish desired,

etc.

as a guideline, wide or hard workpieces, or using

finer grit sandpaper will require a slower feed rate.

the goal in setting the correct feed rate is to pro-

duce the desired results for the operation without

burning the workpiece.

NOTICE

Using too fast of a feed rate may exceed the

sanding motor capacity and trip the motor

or power supply circuit breaker. Using too

slow of a feed rate may burn the surface of

the workpiece.

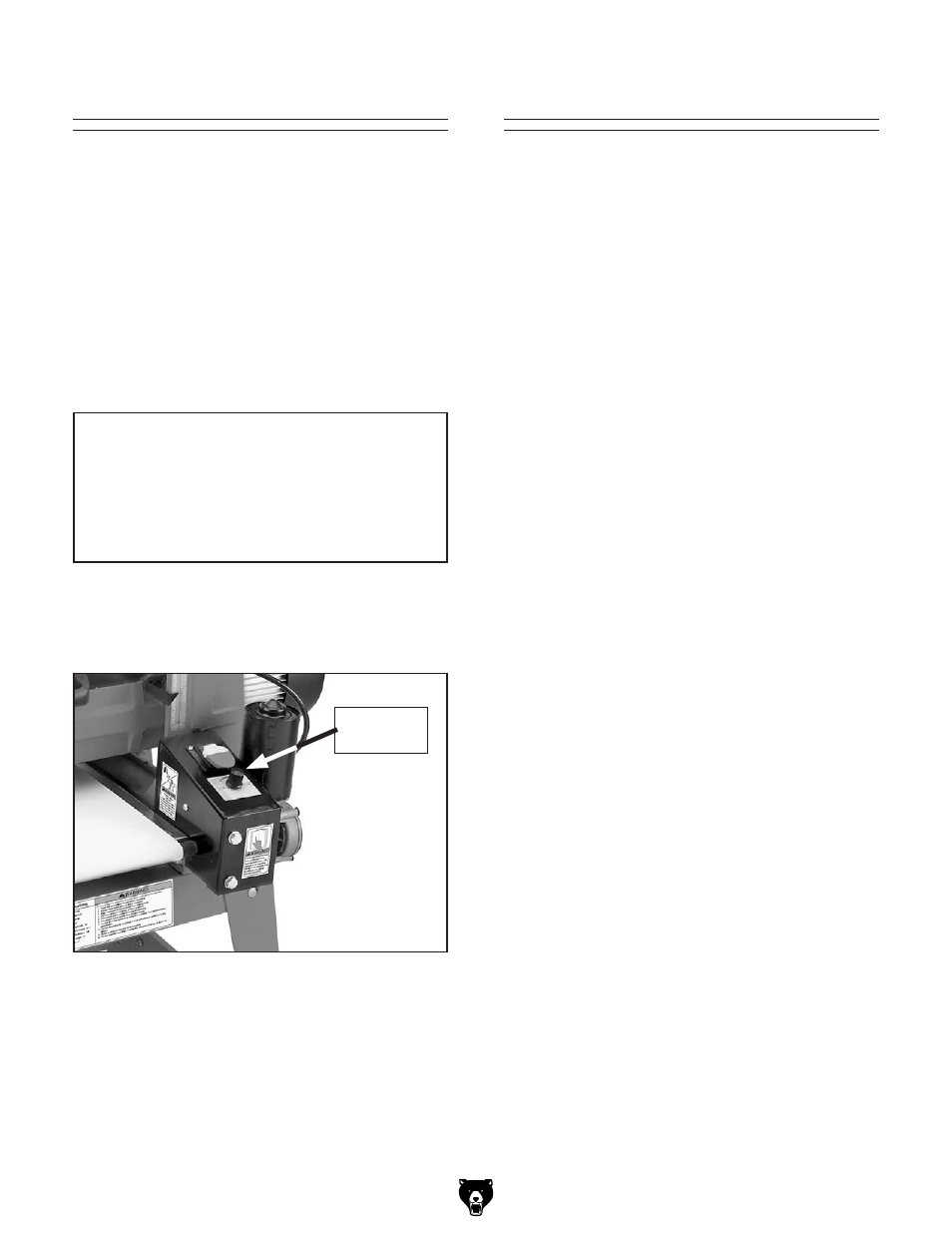

to adjust the conveyor belt feed rate, rotate

the conveyor variable feed rate dial shown in

figure 25.

Note: The ON/OFF switch must be in the ON

position to enable the conveyor motor to run.

Sanding tips

Follow these precautions to ensure safe sanding

operation and quality results:

•

replace the sandpaper with a higher grit to

achieve a finer finish (refer to

Sandpaper on

page 21).

•

When making multiple passes on the

workpiece, do not lower the sanding drum

more than

1

⁄

32

" or

1

⁄

4

turn of the elevation

handwheel for any one pass.

•

if possible, feed the workpiece at a 60° angle

to the sanding drum. this will provide for

more effective material removal, less loading

and more even wear of the sandpaper, and

lighter load on the motors. on the last finish-

ing passes, feed the workpiece so that the

majority of the grain is perpendicular to the

sanding drum.

•

Extend the life of the sandpaper by regularly

using a pro-stiCK© sanding pad (refer to

Accessories on page 28).

•

reduce snipe when sanding more than one

board of the same thickness by feeding them

into the sander with the front end of the sec-

ond board touching the back end of the first

board.

•

do Not edge sand boards. this can cause

boards to kickback, causing serious personal

injury. Edge sanding boards also can cause

damage to the conveyor belt and sandpa-

per.

•

When sanding workpieces with a bow or

crown, place the high point up (prevents the

workpiece from rocking) and take very light

passes.

figure 25. location of the feed rate dial.

Feed rate

dial