Grizzly G0716 User Manual

Page 34

-32-

Model G0716 (Mfg. Since 2/11)

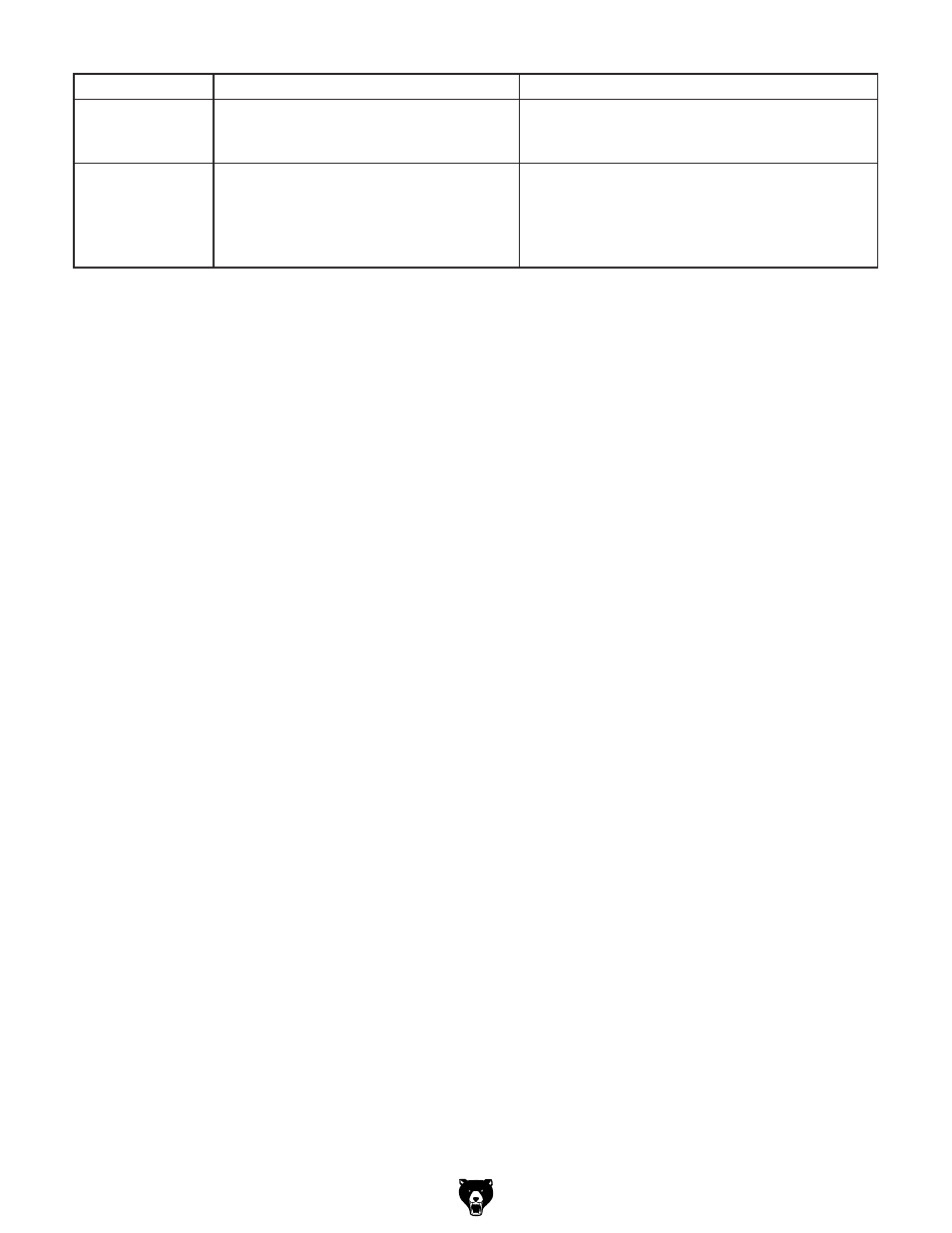

symptom

possible Cause

possible solution

ripples or

lines in workpiece.

1. uneven feed rate.

2. sanding drum deflecting from workpiece.

1. Maintain an even feed rate through the entire

sanding operation.

2. Make sure the elevation lock knob is tight.

snipe marks

in workpiece.

1. improper pressure roller tension.

2. Workpiece too long to be supported

without additional help.

1. Evenly adjust pressure roller tension (see

page 36).

2. use roller stands or tables on the infeed and

outfeed ends of the conveyor to keep the

workpiece from bending.

See also other documents in the category Grizzly Power saws:

- G0506 (56 pages)

- 12" Cold Cut Saw G0682 (52 pages)

- G1127 (3 pages)

- 24" & 27" Resaw Bandsaws G3619 (56 pages)

- H7197 (1 page)

- INDUSTRIAL BANDSAW W/FOOT BRAKE G0513X2F (108 pages)

- Heavy-Duty Table G1023Z (63 pages)

- G0641 (56 pages)

- Air Cut-Off G8122 (2 pages)

- Ultimate 14" Bandsaw G0555 (68 pages)

- G4186Z (48 pages)

- H8145 (36 pages)

- G0691 (11 pages)

- G0691 (92 pages)

- G0592 (60 pages)

- Model G1022proz (84 pages)

- G0605X1-6X1 (12 pages)

- Model G1023zx3 (63 pages)

- G1016 (30 pages)

- H0604 (10 pages)

- ZX (63 pages)

- g0531b (8 pages)

- G3620 (56 pages)

- G1023SL (50 pages)

- G1023SLWX (3 pages)

- 50/65 Ton Ironworker G0647 (76 pages)

- Zero Clearance Table Insert H7396 (1 page)

- H7583 (28 pages)

- G0621 (60 pages)

- G0457 (64 pages)

- G0605X1 (101 pages)

- H0629 (3 pages)

- Slow Speed Cold Cut G0665 (40 pages)

- G0717 (60 pages)

- G0659 (60 pages)

- G0606X1 (12 pages)

- G0605X/G0606X (76 pages)

- G5787 (37 pages)

- G8599 (13 pages)

- T10131 (4 pages)

- G0513P (108 pages)

- G9906 (14 pages)

- G0513X2 (108 pages)

- G7211 (34 pages)

- G1052 (34 pages)