Schedule, General cleaning, Lubrication cleaning sandpaper – Grizzly G0716 User Manual

Page 31

Model G0716 (Mfg. Since 2/11)

-29-

SEctiON 6: MAiNtENANcE

Always disconnect power

to the machine before

performing maintenance.

failure to do this may

result in serious person-

al injury.

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily check

•

loose mounting bolts.

•

damaged, worn, or loaded sandpaper.

•

Worn or damaged wires or switches.

•

Worn or damaged conveyor belt.

•

any other unsafe condition.

Schedule

Cleaning the Model g0716 is relatively easy.

Vacuum excess wood chips and sawdust, and

wipe off the remaining dust with a dry cloth. if any

resin has built up on the sanding drum, remove

the sandpaper strip and use a resin dissolving

cleaner to remove the resin. Clean the conveyor

belt with soapy water.

General cleaning

the bearings on the Model g0716 have been

lubricated and sealed at the factory. No other care

of these bearings is necessary unless they need

replacement.

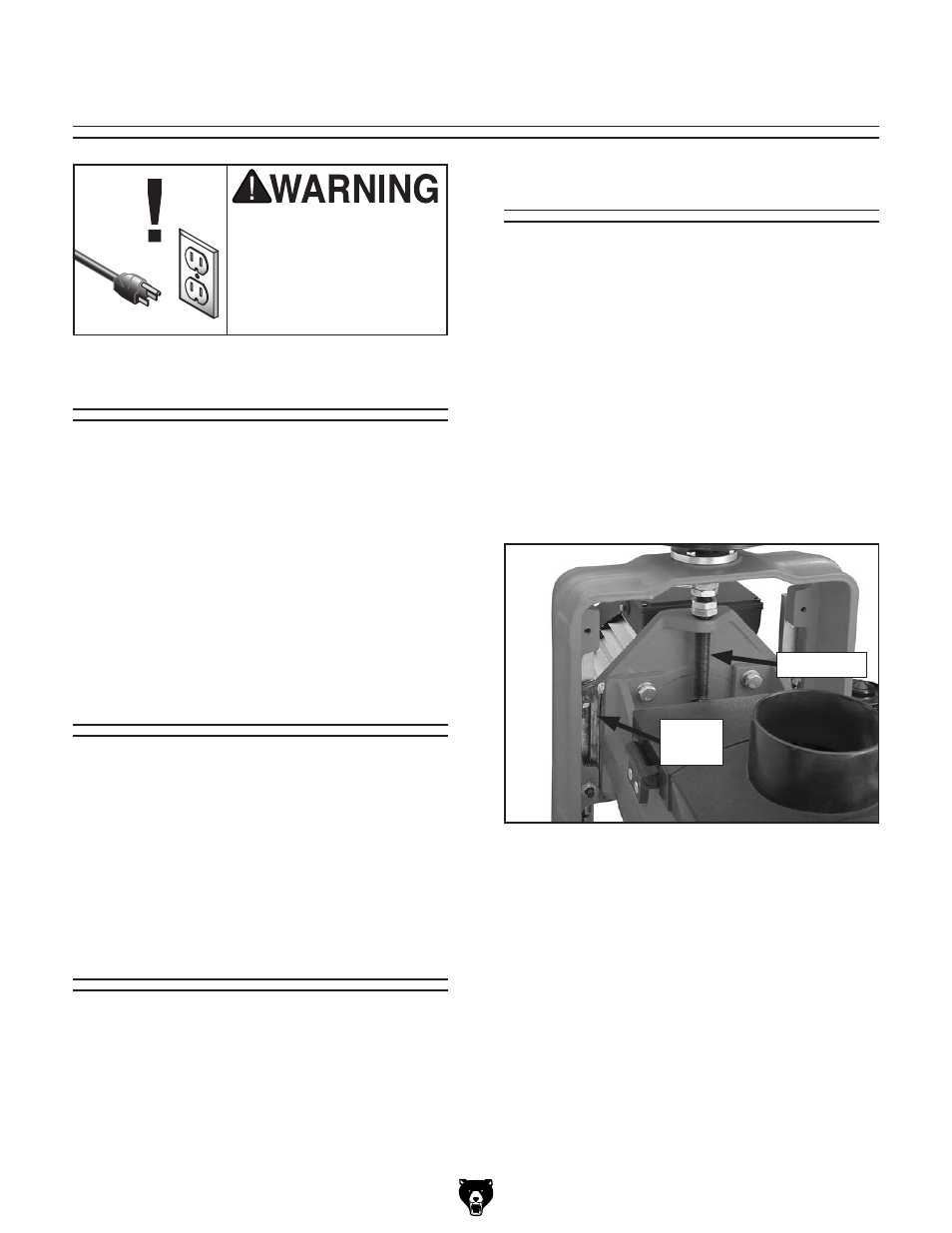

periodically, depending upon usage, clean away

and sawdust or grime from the elevation leadscrew

and the sanding head slides (see

figure 29), then

apply a small amount of dry lubricant, such as

graphite. Move the sanding head through its full

range of motion to distribute the lubricant.

Note: Do not use grease or oil lubricants that will

attract and hold the sawdust.

Lubrication

cleaning Sandpaper

When the sandpaper strip becomes loaded with

built-up sawdust and gum, run a sandpaper

cleaner pad through the machine several times

along the full length of the sanding drum until the

sandpaper is clean (see

page 28 for an option

from grizzly).

figure 29. location of lubrication points.

leadscrew

slide

(1 of 2)