Outboard turning, Sanding/finishing – Grizzly Variable Speed Wood G0632 User Manual

Page 38

-36-

Model G0632 (Mfg. 4/12+)

Outboard Turning

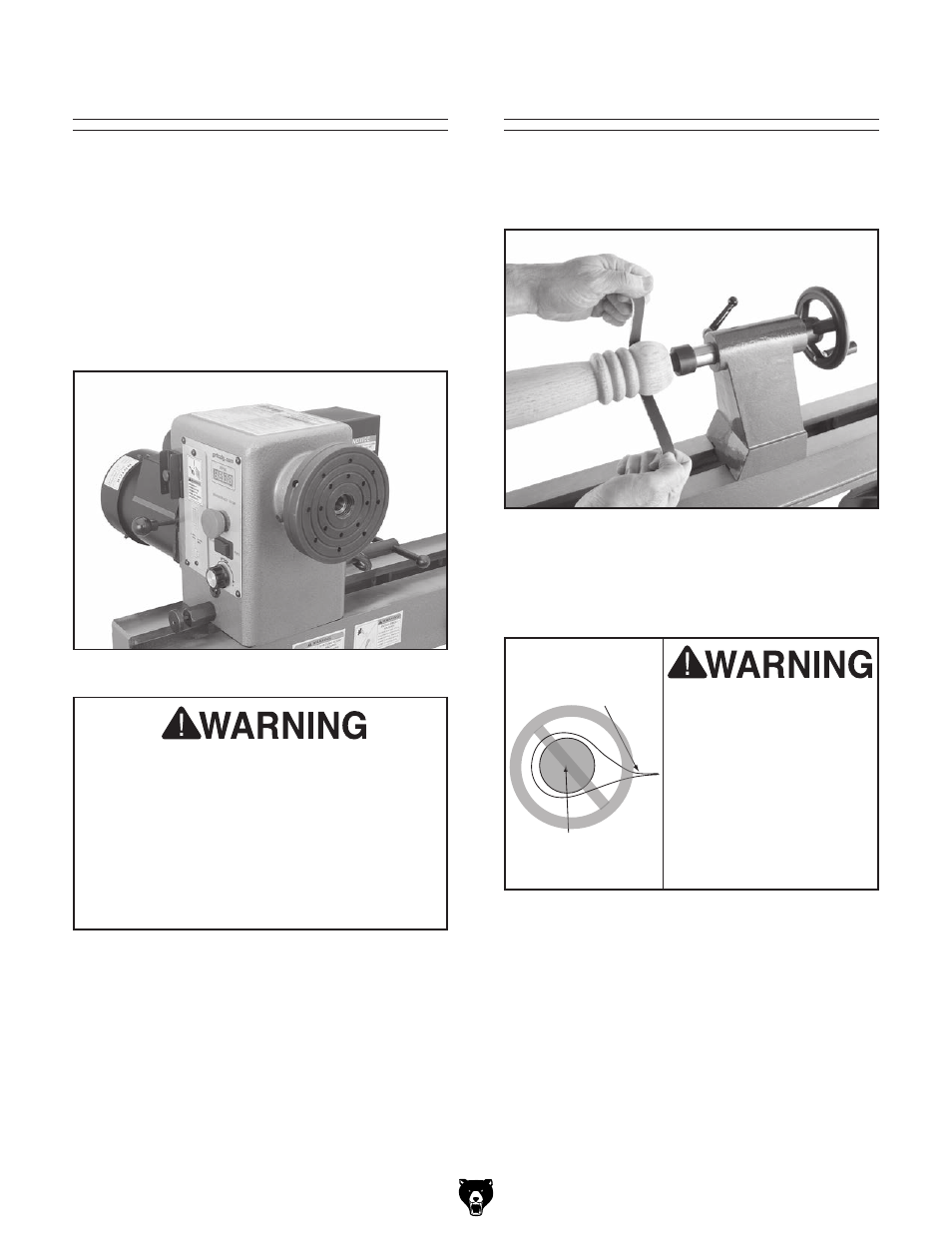

Outboard turning is a variation of faceplate turn-

ing and is usually done when the stock diameter

is greater than 12". For the size of this particular

lathe and its minimum turning speed, we recom-

mend a maximum diameter of 17".

Figure 49 depicts the lathe setup at 90° for turn-

ing larger workpieces. When turning in this man-

ner, you must use a free standing tool rest (not

included).

Figure 49. Headstock set at 90°.

Sanding/Finishing

After the turning operations are complete, the

workpiece can be sanded and finished before

removing it from the lathe (see

Figure 50).

Figure 50. Typical sanding operation.

Note: Whenever sanding or finishing, move the

tool rest holder out of the way to increase per-

sonal safety and gain adequate working room.

Keep the lathe tool resting on a tool rest

the ENTIRE time that it is in contact with

workpiece or when preparing to make con-

tact between lathe tool and workpiece.

Otherwise, the spinning workpiece could

force the lathe tool out of your hands or

entangle your hands into the workpiece.

Failure to heed this warning could result in

serious personal injury.

Wrapping the sandpa-

per completely around

the workpiece could pull

your hands into the mov-

ing workpiece and may

cause serious injury.

Never wrap sandpaper

or finishing materials

completely around the

workpiece.

Sandpaper

Workpiece