Assembly, Mounting to shop floor, Notice – Grizzly Variable Speed Wood G0632 User Manual

Page 19

Model G0632 (Mfg. 4/12+)

-17-

Assembly

To assemble your lathe:

1. Stand the right and left supporting legs up

approximately 47" apart, and get them rea-

sonably aligned, as shown in

Figure 11.

The G0632 and its com-

ponents are very heavy.

Get lifting help or use

power lifting equipment

such as a fork lift to move

heavy items.

Figure 11. Stand legs approximately 47" apart to

prepare for mounting the lathe.

2. Using the help of assistants, carefully lift the

lathe onto the stands and align the mounting

holes.

Note: The headstock end of the lathe is the

heaviest and usually requires two people for

lifting that end.

Although not required, we recommend that you

bolt your new lathe to the floor. Because this

is an optional step and floor materials may

vary, machine feet are included with your lathe.

Generally, you can either bolt your machine to

the floor or mount it on the included machine feet.

Whichever option you choose, we recommend

leveling your machine with a precision level.

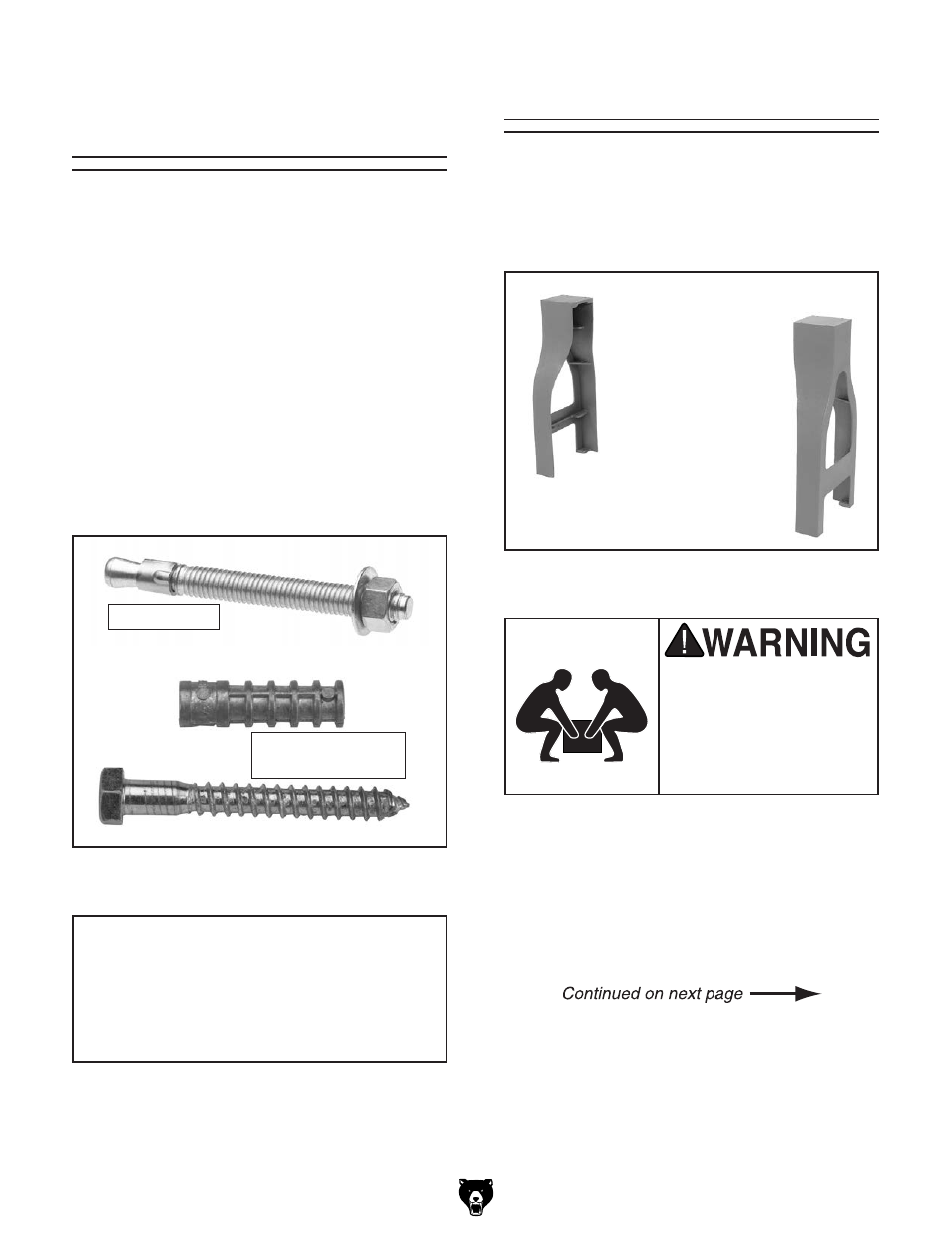

Bolting to Concrete Floors

Lag shield anchors with lag bolts and anchor

studs (

Figure 10) are two popular methods for

anchoring an object to a concrete floor. We sug-

gest you research the many options and methods

for mounting your machine and choose the best

that fits your specific application.

Mounting to Shop

Floor

Mounting to Shop Floor

NOTICE

Anchor studs are stronger and more per-

manent alternatives to lag shield anchors;

however, they will stick out of the floor,

which may cause a tripping hazard if you

decide to move your machine.

Figure 10. Typical fasteners for mounting to

concrete floors.

Anchor Studs

Lag Shield Anchor

and Lag Screw