Operating sequence – Bryant 579F User Manual

Page 52

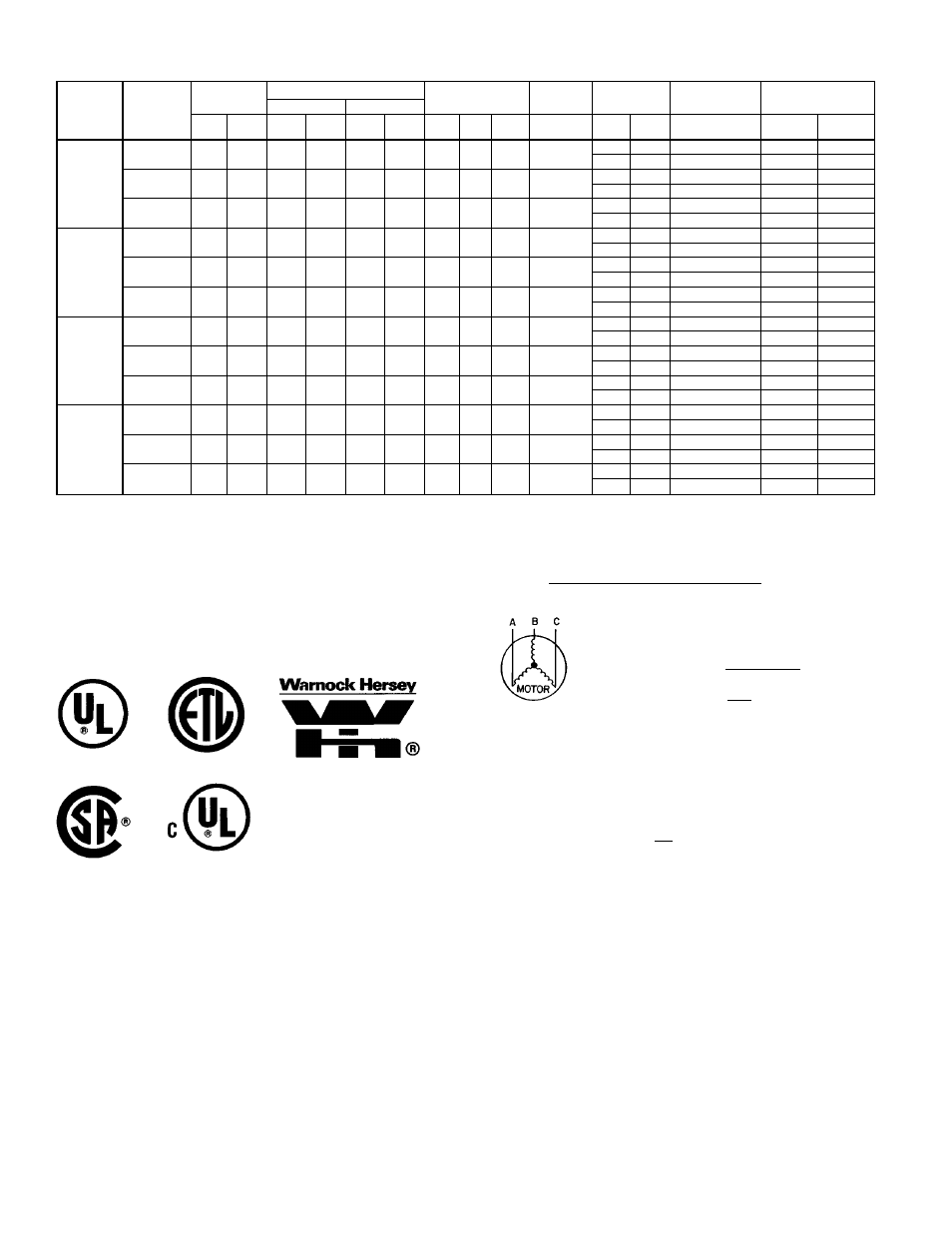

ELECTRICAL DATA — 579F180-300

UNIT

579F

NOMINAL

VOLTAGE

(60 Hz)

VOLTAGE

RANGE

COMPRESSOR

OFM

IFM

POWER

EXHAUST

COMBUSTION

FAN MOTOR**

POWER SUPPLY

NO. 1

NO. 2

Min

Max

RLA

LRA

RLA

LRA

Qty

Hp

FLA

(ea)

FLA

FLA

LRA

FLA

MCA

MOCP†

180

(15 Tons)

208/230

(3 phase)

187

254

61.0

266

—

—

3

1

⁄

2

1.70

10.5/10.5

—

—

0.57

92/92

150/150

4.6

18.8

0.57

96/96

150/150

460

(3 phase)

414

508

28.0

120

—

—

3

1

⁄

2

0.08

4.8

—

—

0.30

42

70

2.3

6.0

0.30

45

70

575

(3 phase)

518

632

23.0

96

—

—

3

1

⁄

2

0.75

3.9

—

—

0.57

35

50

2.1

4.8

0.57

37

60

216

(18 Tons)

208/230

(3 phase)

187

254

28.3

205

25.0

185

3

1

⁄

2

1.70

15.8/15.8

—

—

0.57

81/81

100/100

4.6

18.8

0.57

86/86

110/110

460

(3 phase)

414

508

14.4

104

12.4

89

3

1

⁄

2

0.80

7.9

—

—

0.30

41

50

2.3

6.0

0.30

43

50

575

(3 phase)

518

632

11.4

78

10.4

78

3

1

⁄

2

0.75

6.0

—

—

0.57

33

40

2.1

4.8

0.57

35

45

240

(20 Tons)

208/230

(3 phase)

187

254

34.5

239

28.3

205

2

1

5.50

25.0/25.0

—

—

0.57

107/107

125/125

4.6

18.8

0.57

112/112

125/125

460

(3 phase)

414

508

17.0

119

14.4

104

2

1

2.80

13.0

—

—

0.30

54

70

2.3

6.0

0.30

57

70

575

(3 phase)

518

632

15.2

111

11.4

78

2

1

3.40

10.0

—

—

0.57

47

60

2.1

4.8

0.57

49

60

300

(25 Tons)

208/230

(3 phase)

187

254

43.6

228

43.6

228

2

1

5.50

28.0/28.0

—

—

0.57

137/137

175/175

4.6

18.8

0.57

142/142

175/175

460

(3 phase)

414

508

22.1

114

22.1

114

2

1

2.80

14.6

—

—

0.30

70

90

2.3

6.0

0.30

72

90

575

(3 phase)

518

632

17.9

91

17.9

91

2

1

3.40

13.0

—

—

0.57

60

70

2.1

4.8

0.57

62

80

LEGEND

CSA

— Canadian Standards Association

CUL

— Underwriters’ Laboratory Canada

FLA

— Full Load Amps

HACR

— Heating, Air Conditioning and Refrigeration

IFM

— Indoor (Evaporator) Fan Motor

LRA

— Locked Rotor Amps

MCA

— Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC

— National Electrical Code

OFM

— Outdoor (Condenser) Fan Motor

RLA

— Rated Load Amps

*Used to determine minimum disconnect size per NEC.

†Fuse or HACR circuit breaker.

**The 579F240 and 300 high-heat units have 2 combustion-fan motors.

036-150 Only

180-300 Only

180-300 Only

036-072 Only

090-150 Only

NOTES:

1. In compliance with NEC requirements for multimotor and combination load

equipment (refer to NEC Articles 430 and 440), the overcurrent protective de-

vice for the unit shall be fuse or HACR breaker. Canadian units may be fuse or

circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater

than 2%.

Use the following formula to determine the percent voltage imbal-

ance.

% Voltage Imbalance

max voltage deviation from average voltage

= 100 x

average voltage

EXAMPLE: Supply voltage is 460-3-60.

AB =452 v

BC =464 v

AC =455 v

452 +464 +455

Average Voltage =

3

1371

=

3

= 457

NOTE: The 575-v 580D036-150 units are CSA or CUL only.

Determine maximum deviation from average voltage.

(AB) 457 - 452 = 5 v

(BC) 464 - 457 = 7 v

(AC) 457 - 455 = 2 v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

7

% Voltage Imbalance = 100 x

457

= 1.53%

This amount of phase imbalance is satisfactory as it is below the maximum al-

lowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact

your local electric utility company immediately.

OPERATING SEQUENCE

COOLING, UNITS WITHOUT ECONOMIZER — When thermostat

calls for cooling, terminals G and Y1 are energized. The indoor

(evaporator) fan contactor (IFC) and compressor contactor no. 1

(C1) are energized, and evaporator-fan motor, compressor no. 1

(580D036-150

and

579F216-300)

or

unloaded

compressor

(579F180), and condenser fan(s) start. The condenser-fan motor(s)

runs continuously while unit is cooling. For units with 2 stages of

cooling, if the thermostat calls for a second stage of cooling by en-

ergizing Y2, compressor contactor no. 2 (C2) is energized and com-

pressor

no.

2

starts

(580D090-150

and

579F216-300)

or

compressor no. 1 runs fully loaded (579F180).

HEATING, UNITS WITHOUT ECONOMIZER (580D036-150) —

When the thermostat calls for heating, terminal W1 is energized. In

order to prevent thermostat short-cycling, the unit is locked into the

Heating mode for at least 1 minute when W1 is energized. The

induced-draft motor (IDM) is then energized and the burner ignition

sequence begins. The indoor (evaporator) fan motor (IFM) is ener-

gized 45 seconds after a flame is ignited. On units equipped for two

stages of heat, when additional heat is needed, W2 is energized

and the high-fire solenoid on the main gas valve (MGV) is ener-

gized. When the thermostat is satisfied and W1 is deenergized, the

IFM stops after a 45-second time-off delay.

HEATING, UNITS WITHOUT ECONOMIZER (579F180-300)

NOTE: The 579F180-300 units have 2 stages of heat.

Set thermostat system switch at HEAT or AUTO. position and set

fan switch to AUTO. position for heating.

52