Bryant 579F User Manual

Page 18

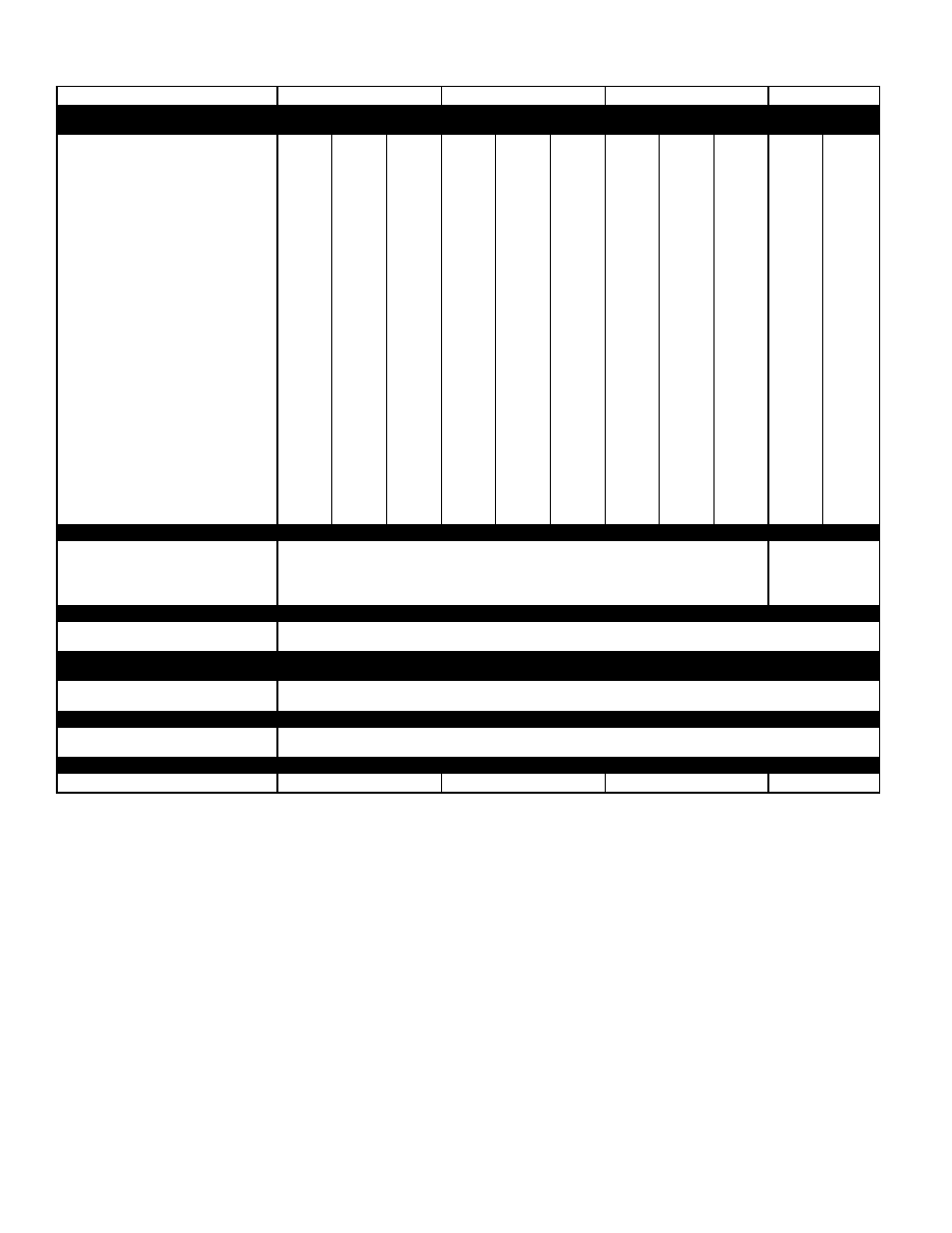

SPECIFICATIONS — 580D090-150 (cont)

UNIT SIZE

090

102

120

150

FURNACE SECTION

Low

Heat

Medium

Heat

High

Heat

Low

Heat

Medium

Heat

High

Heat

Low

Heat

Medium

Heat

High

Heat

Low

Heat

Medium

Heat

Rollout Switch Cutout

Temp (F)†

195

195

195

195

195

195

195

195

195

195

195

Burner Orifice Diameter

(in. ...drill size)

Natural Gas

Std .120...31 .120...31 .120...31 .120...31 .120...31 .120...31 .120...31 .120...31 .129...30 .120...31 .129...30

Liquid Propane

Alt .096...41 .096...41 .096...41 .096...41 .096...41 .096...41 .096...41 .096...41 .102...38 .096...41 .102...38

Pilot Orifice Diameter

(in. ...drill size)

Natural Gas

Std

—

—

—

—

—

—

—

—

—

—

—

Liquid Propane

Alt

—

—

—

—

—

—

—

—

—

—

—

Thermostat Heat Anticipator

Setting (amps)

208/230, 575 v Stage 1

.14

.14

.14

.14

.14

.14

.14

.14

.14

.14

.14

Stage 2

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

460 v Stage 1

.14

.14

.14

.14

.14

.14

.14

.14

.14

.14

.14

Stage 2

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

.20

Gas Input (Btuh) Stage 1

125,000 120,000 180,000 125,000 120,000 180,000 120,000 180,000 200,000 180,000 200,000

Stage 2

—

180,000 224,000

—

180,000 224,000 180,000 224,000 250,000 224,000 250,000

Efficiency (Steady

State) (%)

80

80

80

80

80

80

80

80

80

80

80

Temperature Rise Range

20-50

35-65

45-75

20-50

35-65

45-75

35-65

35-65

40-70

35-65

40-70

Manifold Pressure (in. wg)

Natural Gas

Std

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

Liquid Propane

Alt

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

Gas Valve Quantity

1

1

1

1

1

1

1

1

1

1

1

Gas Valve Pressure Range

Psig

0.180-

0.487

0.180-

0.487

0.180-

0.487

0.180-

0.487

0.180-

0.487

0.180-

0.487

0.180-

0.487

0.180-

0.487

0.180-

0.487

0.180-

0.487

0.180-

0.487

in. wg

5.0-13.5 5.0-13.5 5.0-13.5 5.0-13.5 5.0-13.5 5.0-13.5 5.0-13.5 5.0-13.5 5.0-13.5 5.0-13.5 5.0-13.5

Field Gas Connection

Size (in.)

1

⁄

2

3

⁄

4

3

⁄

4

1

⁄

2

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

3

⁄

4

HIGH-PRESSURE SWITCH (psig)**

Standard Compressor

Internal Relief

450 ± 50

500 ± 50

Cutout

428

428

Reset (Auto.)

320

320

LOW-PRESSURE SWITCH (psig)**

Cutout

7 ± 3

Reset (Auto.)

22 ± 7

FREEZE PROTECTION

THERMOSTAT (F)**

Opens

30 ± 5

Closes

45 ± 5

OUTDOOR-AIR INLET SCREENS

Cleanable

Quantity...Size (in.)

1...20 x 25 x 1

1...16 x 25 x 1

RETURN-AIR FILTERS

Throwaway

Quantity...Size (in.)

4...16 x 20 x 2

4...16 x 20 x 2

4...20 x 20 x 2

4...20 x 20 x 2

LEGEND

Al

— Aluminum

Bhp

— Brake Horsepower

FIOP — Factory-Installed Option

*Evaporator coil fin material/condenser coil fin material.

†Rollout switch is manual reset.

**Requires the accessory controls upgrade kit.

††Weight of 14-in. roof curb.

Low-heat weight/high-heat weight.

¶Circuit 1 consists of lower portion of condenser coil and lower portion of evaporator coil, and Circuit 2 is the upper

portion of both coils.

***The 579F300 unit requires 2-in. industrial-grade filters capable of handling face velocities of up to 625 ft/min.

NOTE: The 580D036-150 units have a loss-of-charge/low-pressure switch (accessory) located in the liquid line. The

579F180-300 units have a low-pressure switch (standard) located on the suction side.

18