Heat & Glo Fireplace 6000TR-OAK User Manual

Page 25

Heat & Glo • 6000TR-OAK, 6000TR-OAK-IPI • 383-901 Rev. K • 5/06

29

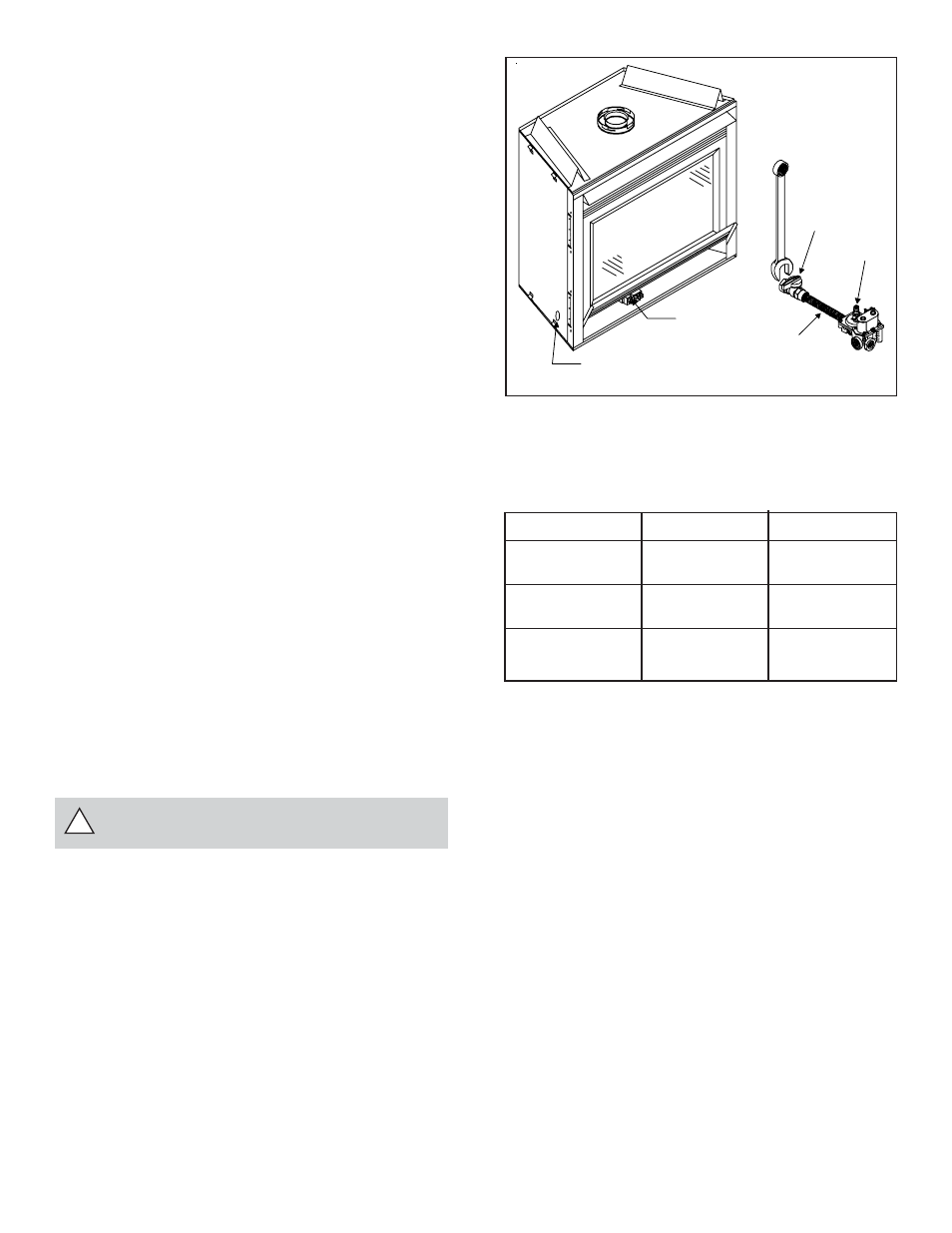

Figure 34. Gas Supply Line

• At the gas line access hole, use insulation to re-pack

the space around the gas pipe.

• Insert insulation from the outside of the fireplace and

pack the insulation tightly to totally seal between the

pipe and the outer casing.

Step 7. The Gas Supply Line

NOTE: Have the gas supply line installed in accordance

with local building codes by a qualified installer ap-

proved and/or licensed as required by the locality. (In

the Commonwealth of Massachusetts installation must

be performed by a licensed plumber or gas fitter).

NOTE: Before the first firing of the fireplace, the gas

supply line should be purged of any trapped air.

NOTE: Consult local building codes to properly size

the gas supply line leading to the 1/2 inch (13mm)

hook-up at the unit.

This gas fireplace is designed to accept a 1/2 inch

(13 mm) gas supply line. To install the gas supply line:

• A listed (and Commonwealth of Massachusetts approved)

1/2 inch (13mm) tee-handle manual shut-off valve and a

listed flexible gas connector are connected to the 1/2

inch (13mm) inlet of the control valve.

NOTE: If substi-

tuting for these components, please consult local codes

for compliance.

• Locate the gas line access hole in the outer casing of

the fireplace.

• The gas line may be run from either side of the fireplace

provided the hole in the outer wrap does not exceed 2 1/2”

in diameter and it does not penetrate the actual firebox.

• The gap between the supply piping and gas access hole

can be plugged with non-combustible insulation to pre-

vent cold air infiltration.

• Open the fireplace lower grille, insert the gas supply line

through the gas line hole, and connect it to the shut-off valve.

• When attaching the pipe, support the control so that the

lines are not bent or torn.

• After the gas line installation is complete, all connec-

tions must be tightened and checked for leaks with a

commercially-available, non-corrosive leak check solu-

tion. Be sure to rinse off all leak check solution following

testing.

WARNING: DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS.

!

Step 8. Gas Pressure Requirements

Pressure requirements for Heat & Glo gas fireplaces

are shown in the table below.

Pressure

Natural Gas

Propane

Minimum

5.0 inches

11.0 inches

Inlet Pressure

w.c.

w.c.

Maximum Inlet

14.0 inches

14.0 inches

Gas Pressure

w.c.

w.c.

Manifold

3.5 inches

10.0 inches

Pressure

w.c.

w.c.

A one-eighth (1/8) inch (3 mm) N.P.T. plugged tapping is

provided on the inlet and outlet side of the gas control for a

test gauge connection to measure the manifold pressure.

Use a small flat blade screwdriver to crack open the screw

in the center of the tap. Position a rubber hose over the tap

to obtain the pressure reading.

The fireplace and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of the system at test pressures in

excess of one-half (1/2) psig (3.5 kPa).

The fireplace must be isolated from the gas supply piping

system by closing its individual shut-off valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than one-half (1/2) psig (3.5 kPa).

Use a wrench on

shut-off valve when

tightening gas line.

CONTROL

VALVE

GAS LINE

ACCESS HOLE

GAS

VALVE

MANUAL

SHUT-OFF

VALVE

FLEX

CONNECTOR