Hustler Turf Lawn Mower User Manual

Page 93

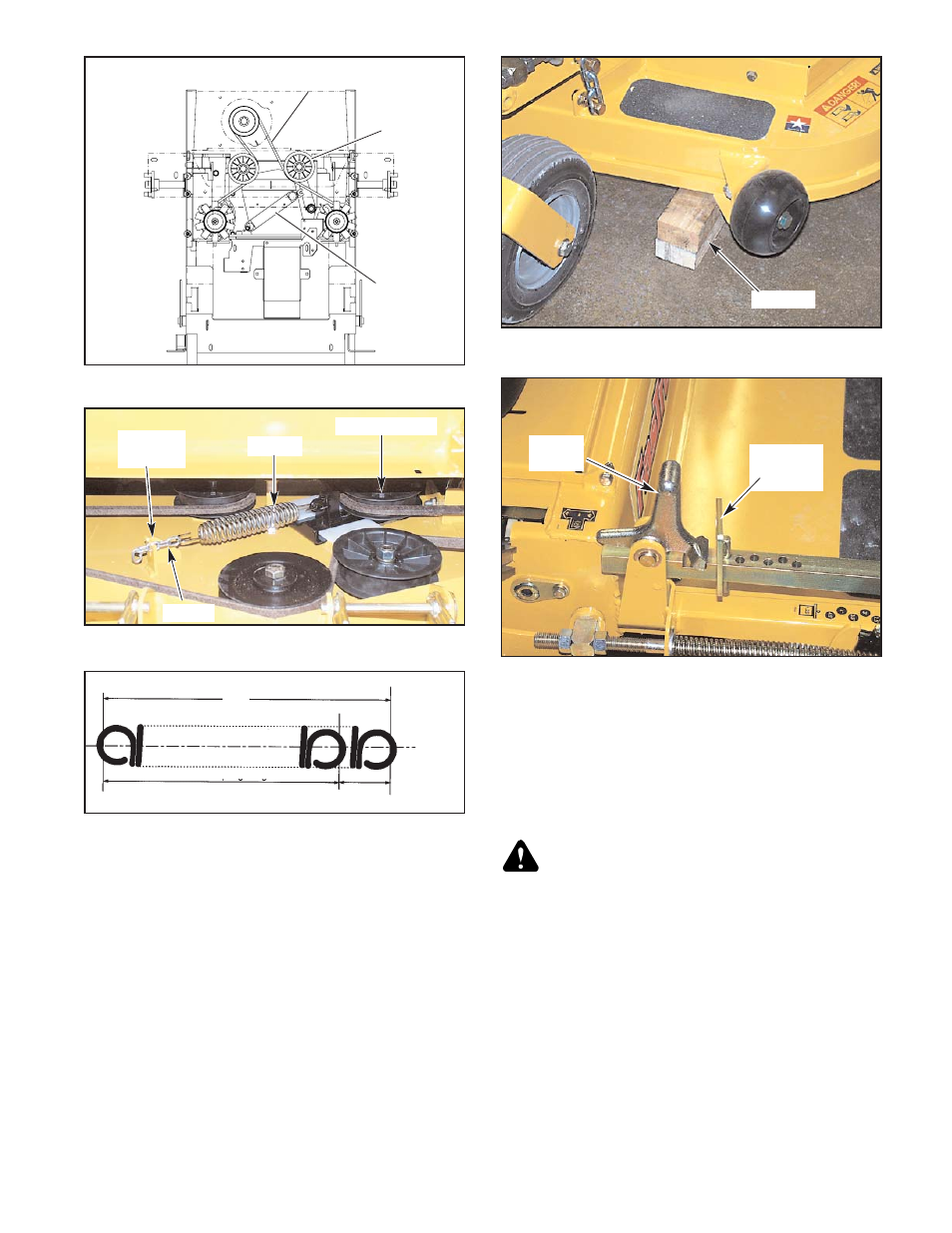

Park brake spring adjustment

Occasionally check the park brake spring adjustment using the following

method:

1. Shut engine off, place control levers in the park brake position,

disengage deck clutch, remove ignition switch key and disconnect

negative battery cable before doing any adjustments.

2. Position the control lever in the neutral position.

3. Make sure the brake actuator lever and the brake link are all the way

down. Fig. 9-28

4. Tighten the nylock nut on top of the spring assembly until it is

touching the top flat washer. Do not compress the spring. Fig. 9-29

5. Place the control lever in the park brake position. The brake pawl

should now be activated and engaging the integrated pump/motor

brake gear. Fig. 9-30

6. Repeat steps 2 thru 4 for the other side.

Park brake switch adjustment

Occasionally the park brake switch may need adjustment. Use the

following method to adjust the switch:

1. Park the unit on a flat surface. Stop the engine and remove the

ignition key. Place control levers in the park brake position.

2. Loosen the screws holding the switch. Fig. 9-28

3. Slide the switch all the way down until it is fully activated (button

pushed in) against the brake actuator lever.

4. Tighten the screws.

Hydraulic pump belt adjustment

The pump drive belt tension remains constant by means of a tension idler

and spring (Fig. 9-31). There is no tension adjustment of this belt. NOTE:

Inspect the belt every 100 hours and replace as needed. Replace the

belt every 200 hours or every two (2) years whichever comes first.

WARNING: If the pump belt fails, loss of control will occur

especially when operating on a slope. If you lose steering

control while operating the machine, place the steering

control levers in the park brake position immediately.

Inspect the machine and involve your Hustler dealer to

resolve the problem before continuing to operate.

Deck drive belt adjustment

The spindle belt tension remains constant by means of a tension idler and

spring (Fig. 9-32). The spring tension should be such that the belt does not

slip under normal operating load conditions, assuming the belt is not

excessively worn or damaged. As belt stretches and wears in, adjustment

may become necessary. To increase belt tension, move the spring chain

one (or more) link(s) at the anchor bracket (Fig. 9-32). Installed spring

length should be 7.50" ± .3" (19.05 cm ± .76 cm) originally with

adjustments of .60" (15.2mm) per chain link. (Fig. 9-32 & 9-33)

IMPORTANT: Do not over tension the spring to compensate for a

badly worn belt or pulley.

Engine RPM setting

The FasTrak 44/52 is designed so that the engine will run at 3400 rpm

with integrated pump/motor load only. At this speed the integrated

pump/motors are running at their maximum rated speed.

Figure 9-35

Height

adjusting

stop

Stop

handle

Figure 9-34

Blocks

Figure 9-31

Spring

Tension

idler

Pump drive

belt

Figure 9-32

Spring

Tension idler

Chain

Anchor

bracket

Figure 9-33

1.50”

Spring Extension

7.50”

6.0”

Normal Spring Length

365262

4/07

9-17