Adjustments – Hustler Turf Lawn Mower User Manual

Page 91

ADJUSTMENTS

Introduction

Your FasTrak 44/52 was adjusted before it left the factory and was

checked during predelivery setup. However, after start-up and continued

use, a certain amount of break-in wear will cause some adjustments to

change.

Remain alert for unusual noises, they could be signaling a problem.

Visually inspect the machine for any abnormal wear or damage. A good

time to detect potential problems is while performing scheduled

maintenance service. Correcting the problem as quickly as possible is the

best insurance.

Clear away heavy build-up of grease, oil and dirt, especially in the

engine and under the seat platform areas; minute dust particle are abrasive

to close-tolerance engine and hydraulic assemblies.

Some repairs require the assistance of a trained service mechanic and

should not be attempted by unskilled personnel. Consult your Hustler

service center when assistance is needed.

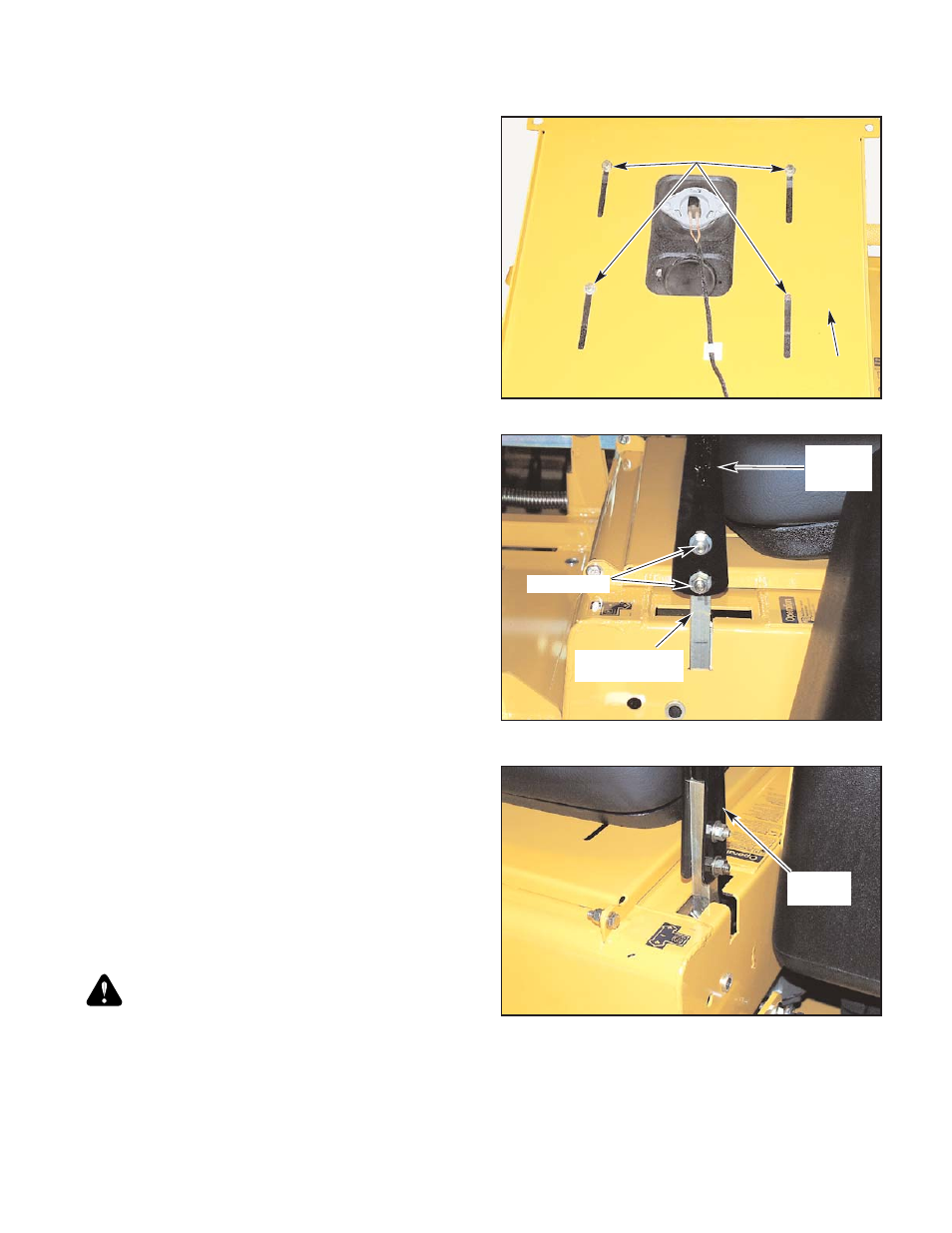

Seat adjustment

The seat can be adjusted forward and rearward by removing the two cap

screws that lock the seat platform in place and pivoting the seat platform up

and forward. Then loosen the four cap screws on the underneath side of the

operator’s platform. Position the seat where you have the best control of

the machine and are the most comfortable and then tighten the cap screws.

Fig. 9-23

Control lever adjustment

The control levers can be adjusted for operator comfort. By loosening

the cap screws that attaches the upper control lever to the lower lever (Fig.

9-24), the upper control lever can be pivoted to fit the operator’s personal

preference.

The control levers can also be adjusted up and down. Remove the cap

screws and slide the upper control lever up or down and align the holes in it

with the holes in lower lever. Re-install the cap screws and tighten.

The control levers should be adjusted so that they align with each other

when in the neutral position.

Steering linkage

The neutral adjustment for the control levers in the neutral position is

discussed in this section.

The tractor steering has been factory adjusted to eliminate creeping

when the control levers are in the neutral position (Fig. 9-25). However,

should the tractor begin to creep, the control lever linkage can be adjusted

as follows:

Control Lever Neutral Adjustment

Before considering any adjustment, check the tire air pressure. Unequal

tire pressure will cause the tractor to drift to one side. Refer to tire pressure

information in the Maintenance section of this manual.

Fine adjustment to the unit’s steering is made with the adjustable pump

linkage rods. Fig. 9-26

Neutral is properly adjusted when the control levers are in the neutral

position and the drive wheels are not turning.

If the tractor creeps in the neutral position the control linkage may be

adjusted as follows:

1. Raise and block the tractor up so the drive wheels are off of the

floor.

WARNING: Never work under the machine or attachment

unless it is safely supported with jack stands. Make certain

machine is secure when it is raised and placed on the jack stands.

The jack stands should not allow the machine to move when the

engine is running and the drive wheels are rotating. Use only

certified jack stands. Use only appropriate jack stands, with a

minimum weight rating of 2000 pounds to block the unit up. Use

in pairs only. Follow the instructions supplied with the vehicle

stands.

2. Position the control lever in the neutral position. Disengage the

deck clutch switch Fig. 9-25.

3. Loosen the nut on the steering dampener’s rear ball stud. Fig. 9-26

4. Remove the cotter key that connects the brake link to the brake

pawl. Remove the brake link from the brake pawl. Fig. 9-30

5. Start the engine and observe which way the wheels are rotating.

6. If wheel(s) are rotating forward, loosen the jam nuts on the pump

linkage rods and rotate the rod to lengthen the steering control

linkage until the wheel(s) come to a stop. Fig. 9-26

NOTE: The left linkage controls the left integrated pump/motor and

the right linkage controls the right integrated pump/motor.

Repeat for the opposite side if necessary.

Figure 9-25

Control lever in the

neutral position

Control

lever

Figure 9-23

Cap screw

Operator’s

platform

365262

4/07

9-15

Figure 9-24

Cap screw

Upper

control

lever

Lower control

lever