Table 11, Suggested transmitter location for given process – Honeywell ST 3000 User Manual

Page 45

4.2

Piping ST 3000 Transmitter,

Continued

Piping Arrangements,

continued

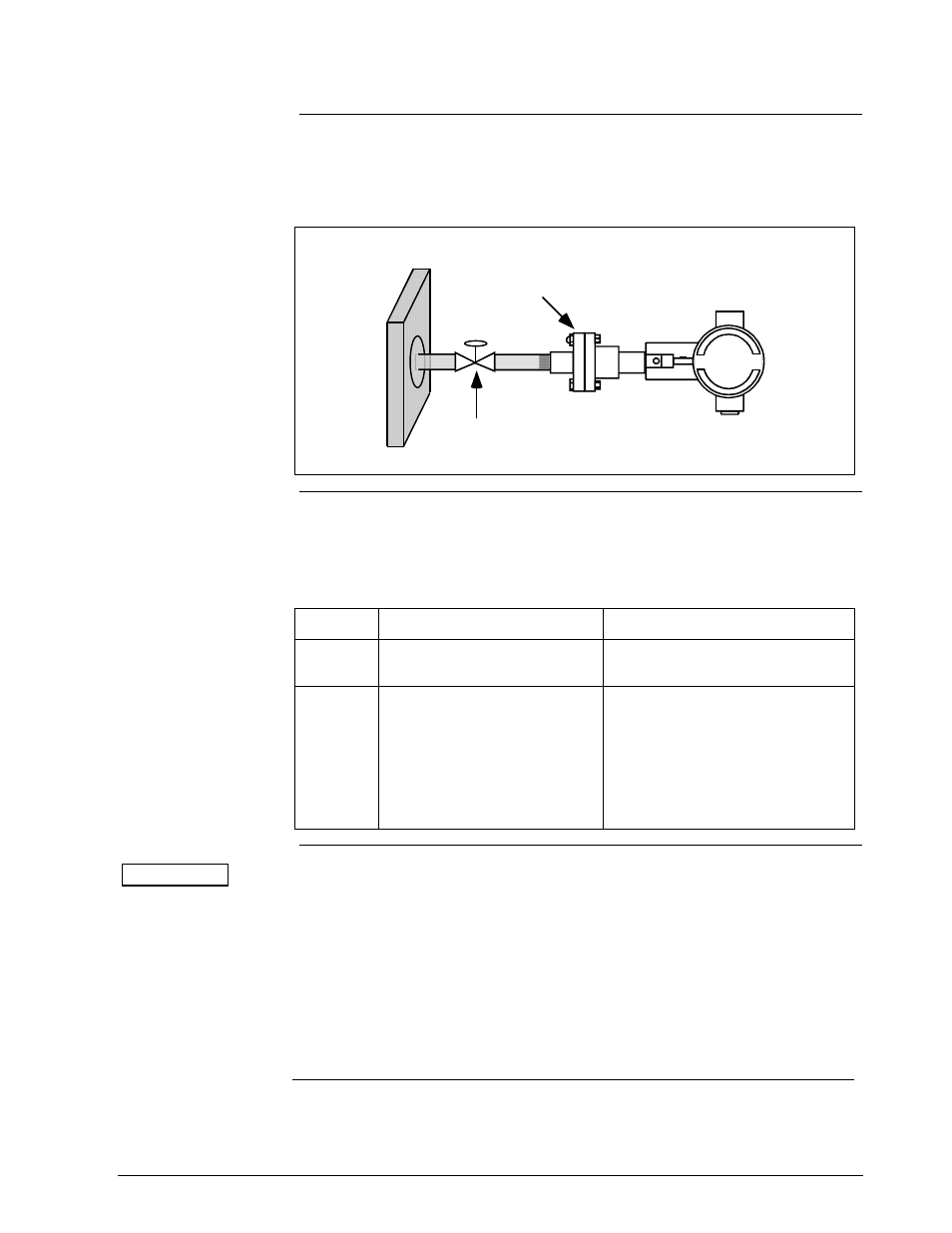

Another piping arrangement uses a block-off valve and a tee connector in

the process piping to the transmitter as shown in Figure 12.

Figure 12

Typical Arrangement for ½” NPT Process Connection Piping

Block-off Valve

1/2" NPT

Connection

Tank Wall

Transmitter location

Table 11 lists the mounting location for the transmitter depending on

the process.

Table 11

Suggested Transmitter Location for Given Process

Process Suggested

Location

Explanation

Gases

Above the gas line

The condensate drains away from

the transmitter.

Liquids

1. Below but close to the

elevation of the process

connection.

2. Level with or above the

process connection.

1. This minimizes the static head

effect of the condensate.

2. This requires a siphon to

protect the transmitter from

process steam. The siphon

retains water as a “fill fluid.”

ATTENTION

For liquid or steam, the piping should slope a minimum of 25.4 mm

(1 inch) per 305 mm (1 foot). Slope the piping down towards the

transmitter if the transmitter is below the process connection so the

bubbles may rise back into the piping through the liquid. If the

transmitter is located above the process connection, the piping should

rise vertically above the transmitter; then slope down towards the

flowline with a vent valve at the high point. For gas measurement, use a

condensate leg and drain at the low point (freeze protection may be

required here).

Continued on next page

2/05

ST 3000 Release 300 Installation Guide

35