2 piping, 3000 transmitter – Honeywell ST 3000 User Manual

Page 44

4.2

Piping ST 3000 Transmitter

Summary

The actual piping arrangement will vary depending upon the process

measurement requirements and the transmitter model. Except for

flanged and remote diaphragm seal connections, process connections are

made to ¼ inch or ½ inch NPT female connections in the process head

of the transmitter’s meter body. For example, a differential pressure

transmitter comes with double ended process heads with ¼ inch NPT

connections but they can be modified to accept ½ inch NPT through

optional flange adapters. Some gauge pressure transmitters may have a

½ inch NPT connection which mounts directly to a process pipe.

The most common type of pipe used is ½ inch schedule 80 steel pipe.

Many piping arrangements use a three-valve manifold to connect the

process piping to the transmitter. A manifold makes it easy to install

and remove or rezero a transmitter without interrupting the process. It

also accommodates the installation of blow-down valves to clear debris

from pressure lines to the transmitter.

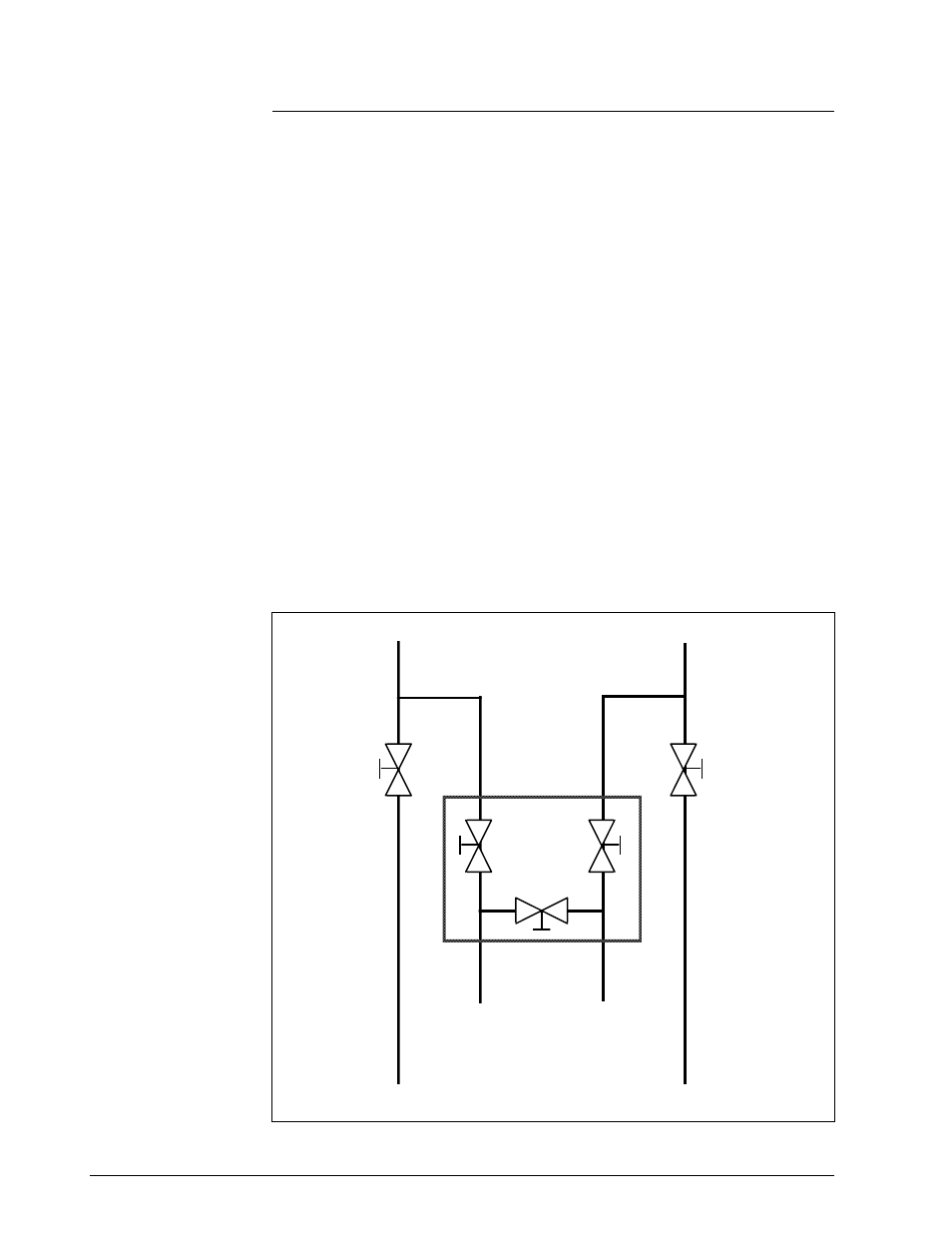

Figure 11 shows a diagram of a typical piping arrangement using a

three-valve manifold and blow-down lines for a differential pressure

transmitter being used to measure flow.

Figure 11

Typical 3-Valve Manifold and Blow-Down Piping

Arrangement.

Blow-Down

Valve

3-Valve

Manifold

To Upstream Tap

To Downstream Tap

To Low Pressure

Side of Transmitter

To High Pressure

Side of Transmitter

Blow-Down

Valve

Blow-Down

Piping

To Waste

To Waste

Blow-Down

Piping

21010

Continued on next page

34

ST 3000 Release 300 Installation Guide

2/05