Water quality, Water connections, Water quality guidelines – WaterFurnace Envision (XL) User Manual

Page 11: Interior piping

ENVISION 7-25 TONS INSTALLATION MANUAL

12

Water Connections

All supply and return water connections are female pipe thread of size specified in physical dimensions. Never use flexible

hoses smaller than separate water connections on the unit and limit hose length to 10 ft. per connection. Check carefully for

water leaks.

Interior Piping

All units are recommended to be connected to supply and return piping in a two-pipe reverse return configuration. A

reverse return system is inherently self-balancing and requires only trim balancing when multiple quantities of units with

different flow and pressure drop characteristics are connected to the same loop. A direct return system may also be made

to work acceptably, but proper water flow balance is more difficult to achieve and maintain.

Supply and return runouts are usually connected to the unit by short lengths of high pressure flexible hose which are sound

attenuators for both unit operating noise and hydraulic pumping noise. One end of the hose should have a swivel fitting to

facilitate removal for service. Hard piping can also be connected directly to the unit although it is not recommended since

no vibration or noise attenuation can be accomplished. The hard piping must have unions to facilitate unit removal (see

figure 1 & 6) for typical application).

Some flexible hose threaded fittings are supplied with sealant compound. If not, apply Teflon tape to assure a tight seal.

Supply and return shutoff valves are required at each unit. The return shutoff valve can be used for balancing and should be

adjusted for proper flow required, or a manual or automatic flow control device should be on the leaving water hose assembly.

No unit should be connected to the supply and return piping until the water system has been cleaned and flushed

completely. After the cleaning and flushing has taken place, the initial connection should have all valves wide open in

preparation for water system filling.

Water Quality Guidelines

In ground water situations where scaling could be heavy or where biological growth such as iron bacteria will be present,

a closed loop system is recommended. The heat exchanger coils in ground water systems may, over a period of time, lose

heat exchange capabilities due to a buildup of mineral deposits inside. These can be cleaned, but only by a qualified service

mechanic, as special solutions and pumping equipment are required. Hot water generator coils can likewise become scaled

and possibly plugged. In areas with extremely hard water, the owner should be informed that the heat exchanger may

require occasional flushing.

Units with cupronickel heat exchangers are recommended for open loop applications due to the increased resistance to

build-up and corrosion, along with reduced wear caused by acid cleaning.

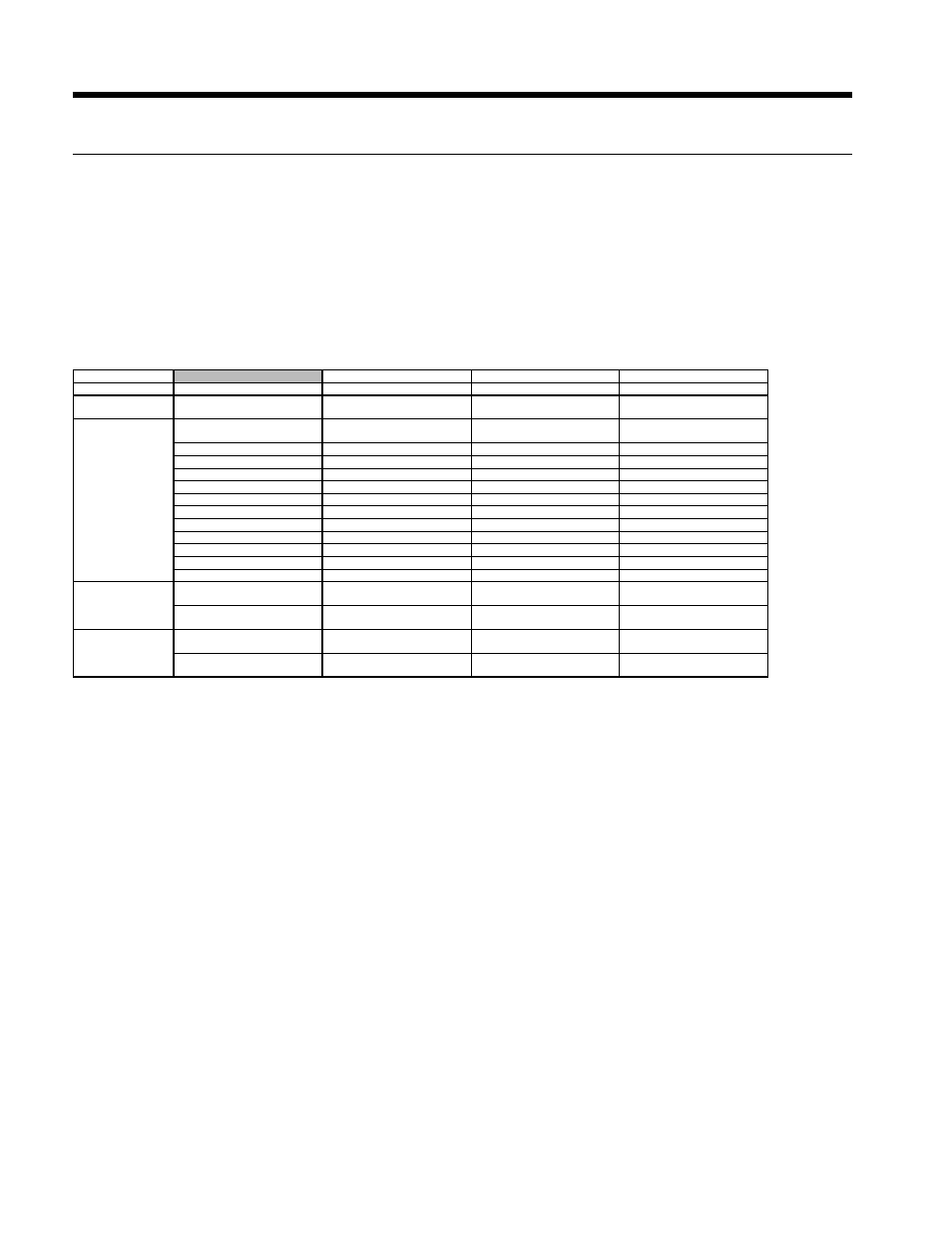

Material

Copper

90/10 Cupronickel

316 Stainless Steel

pH

Acidity/Alkalinity

7 - 9

7 - 9

7 - 9

Scaling

Calcium and

Magnesium Carbonate

(Total Hardness)

less than 350 ppm

(Total Hardness)

less than 350 ppm

(Total Hardness)

less than 350 ppm

Corrosion

Hydrogen Sulfide

Less than 0.5 ppm (rotten egg

smell appears at 0.5 ppm)

10 - 50 ppm

Less than 1 ppm

Sulfates

Less than 125 ppm

Less than 125 ppm

Less than 200 ppm

Chlorine

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Chlorides

Less than 20 ppm

Less than 125 ppm

Less than 300 ppm

Carbon Dioxide

Less than 50 ppm

10 - 50 ppm

10 - 50 ppm

Ammonia

Less than 2 ppm

Less than 2 ppm

Less than 20 ppm

Ammonia Chloride

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Ammonia Nitrate

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Ammonia Hydroxide

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Ammonia Sulfate

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Total Dissolved Solids (TDS)

Less than 1000 ppm

1000 - 1500 ppm

1000 - 1500 ppm

LSI Index

+0.5 to -0.5

+0.5 to -0.5

+0.5 to -0.5

Iron Fouling

(Biological Growth)

Iron, FE

2

+ (Ferrous)

Bacterial Iron Potential

< 0.2 ppm

< 0.2 ppm

< 0.2 ppm

Iron Oxide

Less than 1 ppm, above this

level deposition will occur

Less than 1 ppm, above this

level deposition will occur

Less than 1 ppm, above this

level deposition will occur

Erosion

Suspended Solids

Less than 10 ppm and filtered

for max. of 600 micron size

Less than 10 ppm and filtered

for max. of 600 micron size

Less than 10 ppm and filtered

for max. of 600 micron size

Threshold Velocity

(Fresh Water)

< 6 ft/sec

< 6 ft/sec

< 6 ft/sec

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

2/22/12

Water Quality