Vortech 2000-2008 Honda S2000 User Manual

Page 28

P/N: 4HS020-010

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

21OCT08 v4.0 S2000(4HS020-010v4.0)

16

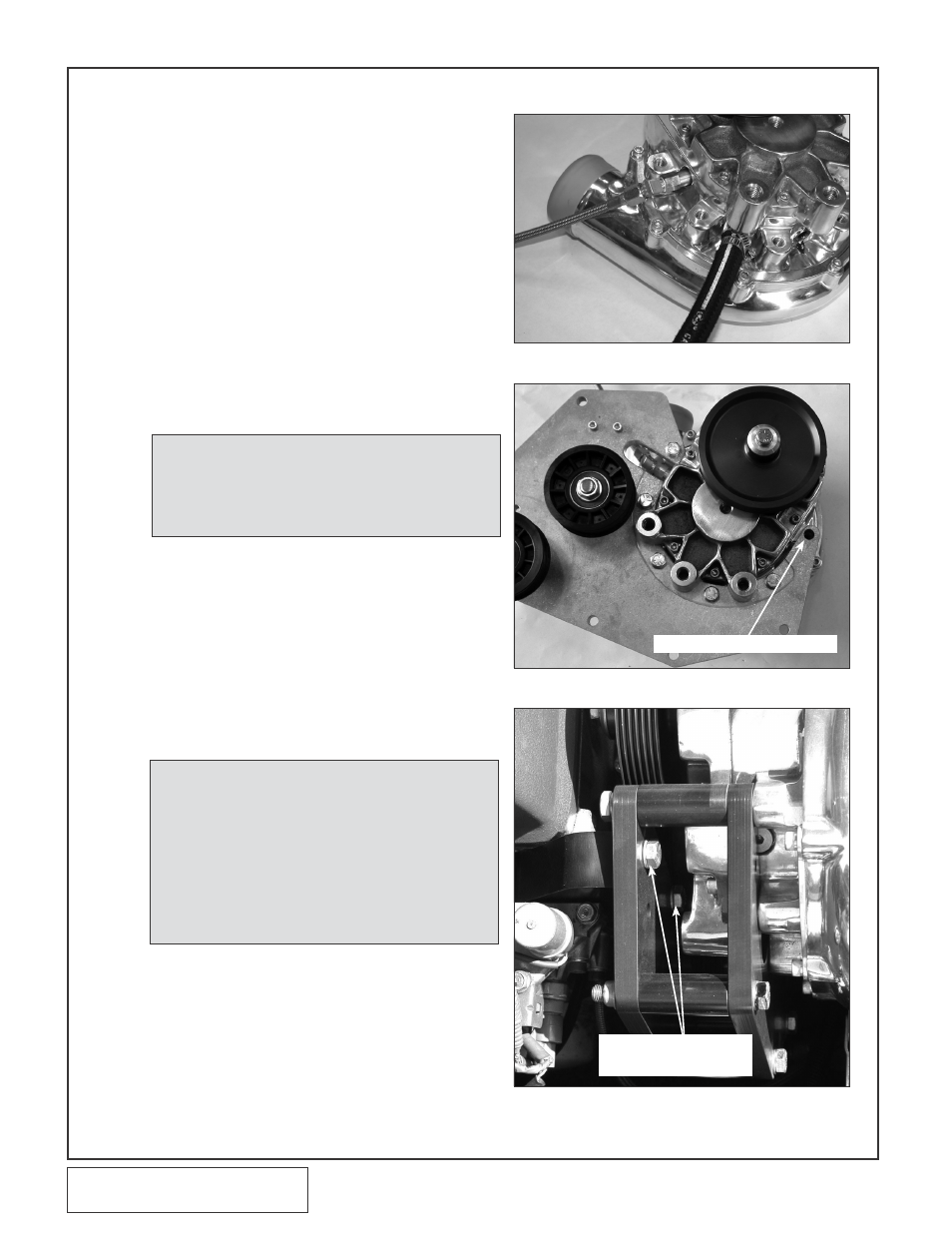

Secure with a #8 hose clamp. Make sure that

the hose clamp housing is clocked down

toward the supercharger so that it will not

cause interference with the supercharger

mounting plate that is to be installed. (See

Fig. 8-j.)

H. (2000-2005 Models Only) Remove the

blue plastic dust cap located on the brass oil

feed nozzle on the side of the supercharger.

Thread the supplied steel 1/8" NPT x 45° x

–4JIC fitting into the supercharger oil feed

nozzle. Carefully tighten and clock the 45° fit-

ting as shown in Figs. 8-j, 8-k. Use caution

when tightening the oil feed fitting, as the

brass nozzle may be broken if care is not

exercised. Connect the supplied oil feed line

to the flare fitting. Temporarily cover the open

end from debris until the connection is made

to the engine in step 15.

I.

Attach the supercharger unit to the mounting

plate as shown using the five supplied 3/8-16

x 1.25" screws with AN washers. The sixth

supercharger mounting hole should remain

empty at this time. (Refer back to Fig. 8-e,

and Fig. 8-k.)

J.

Using two of the supplied 3/8-16 x 1.25"

screws with AN washers, attach the upper

supercharger support plate to the super-

charger mounting block as shown in Figs. 8-l,

8-m. Thread the screws down until the heads

almost touch the plate/washers. Do not tight-

en the screws at this time.

K. From the back side, slide the supplied 3/8-16

x 3.5" screw and AN washer through the top

hole (refer to Figs. 8-n, 8-o) of the upper sup-

port plate and into one of the supplied Ø.875

O.D. x 1.858" long spacers. Loosely mount

the support plate assembly with spacer onto

the supercharger and previously assembled

main supercharger plate.

NOTE: Use only clean engine oil on the pipe

threads. teflon tape or pipe sealant is not

recommended as it might loosen and

cause blockage of the small oil feed orifice

resulting in possible supercharger failure.

NOTE: when directed, it is important to follow the

suggestion: “do not tighten the screws”.

Failure to follow this direction will result in

bracket misalignment and the possibility of

the Vtec solenoid not maintaining a prop-

er seal. thread the applicable screws and

nuts in until the head almost touches down

(.01-.02" clearance). this will allow the

bracket to properly align itself to the

engine and other components in the

assembly during installation.

8. SUPERCHARGER MOUNTING BRACkET/PLATE INSTALLATION, cont’d.

Fig. 8-j (2000-2005 only)

Fig. 8-k

Fig. 8-l

no FaStener Here at tHiS tiMe

3/8-16 x 1.25

ScrewS witH an waSHerS

(do not tigHten)