Drive shaft and supercharger installation, cont’d – Vortech 2000-2003 Ford Focus Zetec/SVT User Manual

Page 19

P/N: 4FJ020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

19APR04 v3.0 Focus(4FJ v3.0)

7

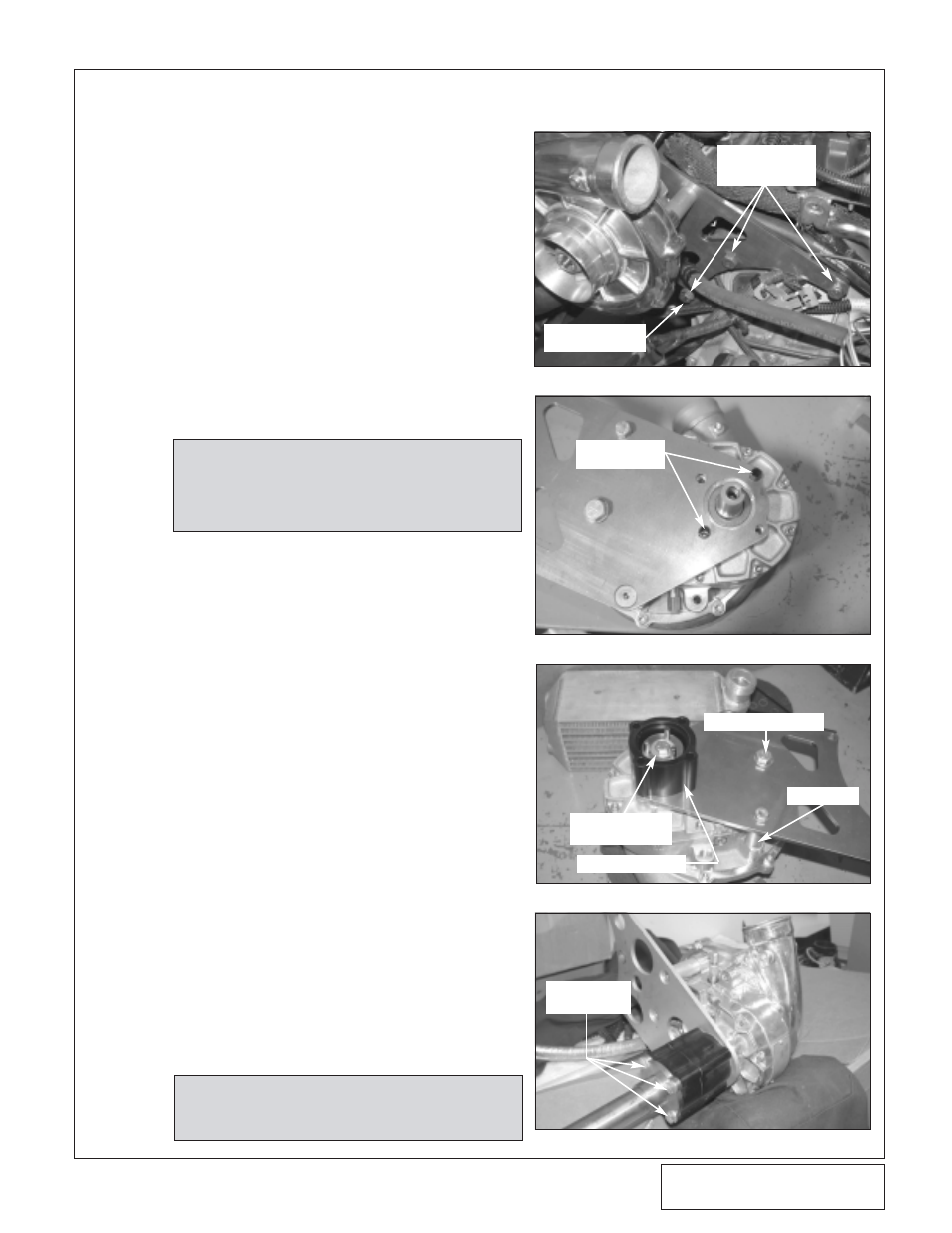

D.

Install the supercharger mounting plate on

the alignment dowels and tap the plate lightly

until it is flush with the supercharger gear

case. (See Fig. 8-b.)

E.

Align the counter bores in the black coupler

housing with the alignment dowels passing

through the supercharger mounting plate.

Lightly tap the drive housing until it is flush

with the mounting plate. (See Fig. 8-c.)

F.

Install onto the supercharger input shaft, the

supplied key and drive coupling containing

three 1/4" diameter dowel pins protruding

from it. (Apply a thin film of anti-seize or

grease onto the inside diameter of the cou-

pling before installing onto the input shaft.)

Secure the coupling with the supplied 3/8"-24

x .75" HXHD and Ø1.0 O.D. washer.

8.

DRIVE SHAFT AND SUPERCHARGER INSTALLATION, Cont’d,

Fig. 8-a

Fig. 8-b

Fig. 8-c

Fig. 8-d

NOTE:

Heat may also be necessary to install the

coupling onto the shaft. (A propane

torch will make this easier if needed.)

Use a light thread lock compound on the

3/8"-24 x .75" screw threads.

NOTE:

It is necessary to leave the hardware

loose to allow for the correct clocking of

the housing assembly upon final installa-

tion. (See Fig. 8-d.)

G.

Install the two supplied 1.80" spacers

between the supercharger and the mounting

plate. Secure in one location with a 3/8"-16 x

2.5" flathead and in the other with a 2.75"

HXHD. Leave both fasteners loose at this

time. (See Fig. 8-c.)

H.

In the middle mounting location, secure the

supercharger to the mounting plate with the

supplied 12mm x 1.75" x 25mm screw and

washer. Leave the fastener loose at this time.

(See Fig. 8-c.)

I.

Locate the preassembled drive shaft assem-

bly. Connect the three-pin coupler from the

end of the drive shaft to the three-pin coupler

on the supercharger assembly using the sup-

plied composite ring. Align the hole patterns

so that one side of pins is alternating with the

opposite side of pins. Each pin will have its

own hole. Verify that each set of pins is

inserted into the raised bosses with holes

on their corresponding side of the com-

posite ring. Push together until each coupler

is flush with the composite ring. (See Figs. 8-

d and the boxed section of Fig 8-f.)

J.

With the couplers aligned, align the two cou-

pler housings. Using the four 5/16"-18 x 5.25"

HXHD screws secure the drive shaft assem-

bly to the supercharger assembly.

K.

Lower the supercharger and drive assembly

12mm x 1.25 x 25mm

1.8" SPACER

0.630 O.D.

SPACER LOCATION

INSTALLED

Ø5/16" DOWELS

INSTALLED DRIVE

COUPLING

COUPLER HOUSING

LEAVE LOOSE

UNTIL STEP O

3 LOCATIONS TO

REMOVE STOCK

HARDWARE