SOR Single Point Ultrasonic Level Switch User Manual

Page 2

2/16

Form 841 (08.13) ©SOR Inc.

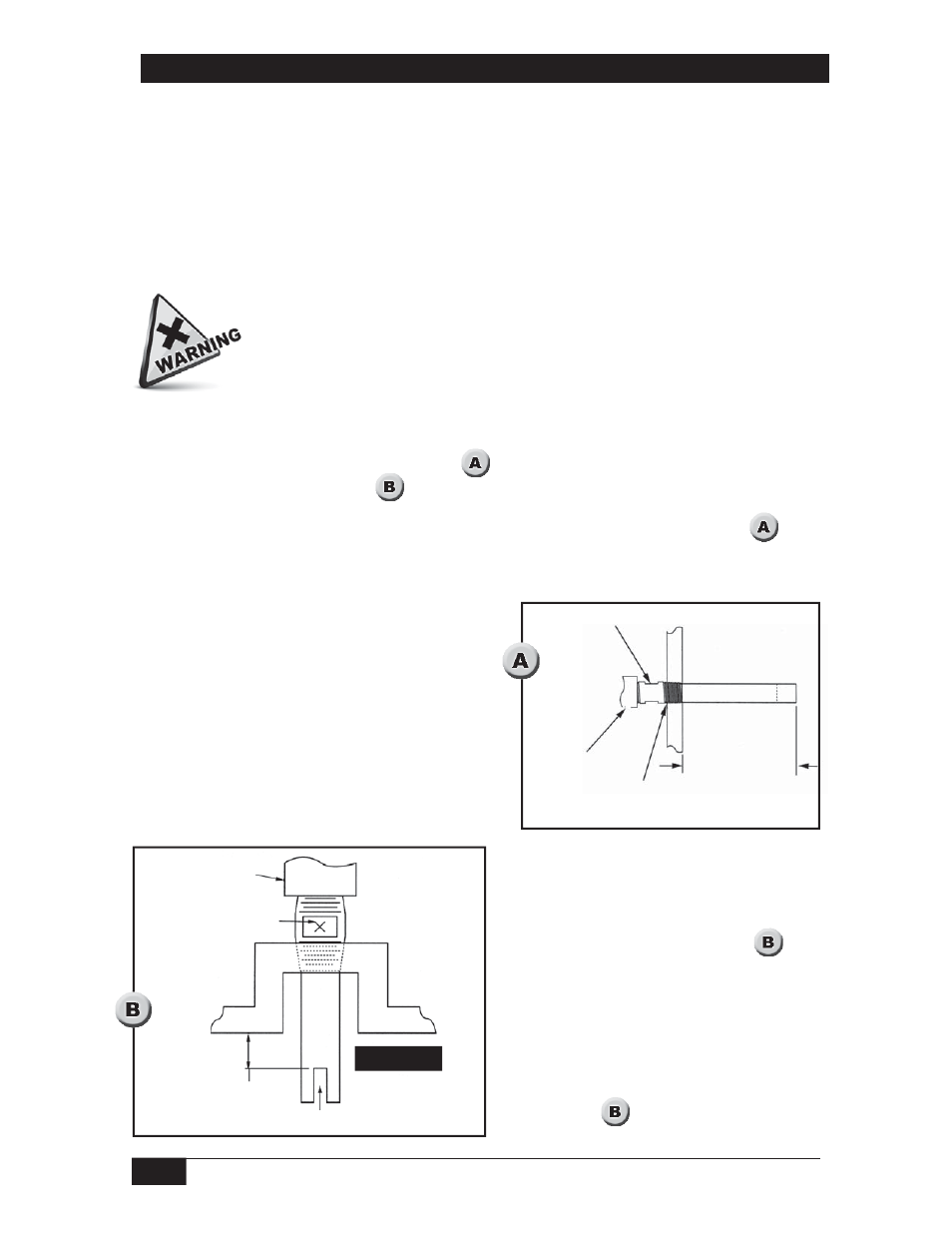

Housing Hub

Alignment mark X

on wrench flat

at 12 o’clock

Alternate

position for

alignment

mark X at

6 o’clock

1 inch

minimum

Sensor Cavity

TOP VIEW

DO NOT weld any part of this instrument.

Wrench Flat

Housing

Hub

Apply

thread sealant

No

Obstructions

Horizontal Mounting

Horizontal mounting is recommended for use

in highly viscous liquids, or liquids containing

sludge and debris. When tightened securely, the

sensor cavity must be perpendicular to the liquid

surface for optimum drainage when process

liquid level drops below the sensor cavity.

Tank or Vessel

Make sure that the sensor can be fully inserted and tightened without interference from

obstructions inside the tank or vessel. (See

). The sensor cavity must clear the inner

wall by one inch/25.4 mm. (See

)

Apply suitable sealant to the process connection to prevent process leakage. (See

)

Use an open end wrench to tighten the sensor into the process connection.

Do not use the sensor base as a handle to tighten the process connection.

An alignment mark X stamped on a

wrench flat (or on the dry face of a

flange below the housing) shows

sensor cavity orientation. (See

)

Optimum drainage occurs when the X

mark is located at 6 or 12 o’clock. The

sensor must project through a tank

fitting so that the sensor cavity is at

least 1” beyond the inner wall of the

tank. (See

y

)

Installation

Ultrasonic Level Sensors can be mounted by inserting the sensor through a fitting in a

vessel, or the sensor may be suspended over an open sump or basin.

Keep the sensor cavity out of the direct flow of liquid fill to prevent false readings. Install a

baffle to divert liquid flow if necessary.

Avoid installation of sensor in turbulent areas such as pump discharge or suction. Air

pockets may be present in these areas which may cause false indication.