Troubleshooting – SOR Single Point RF Level Switch User Manual

Page 10

10/12

Form 830 (03.13) ©SOR Inc.

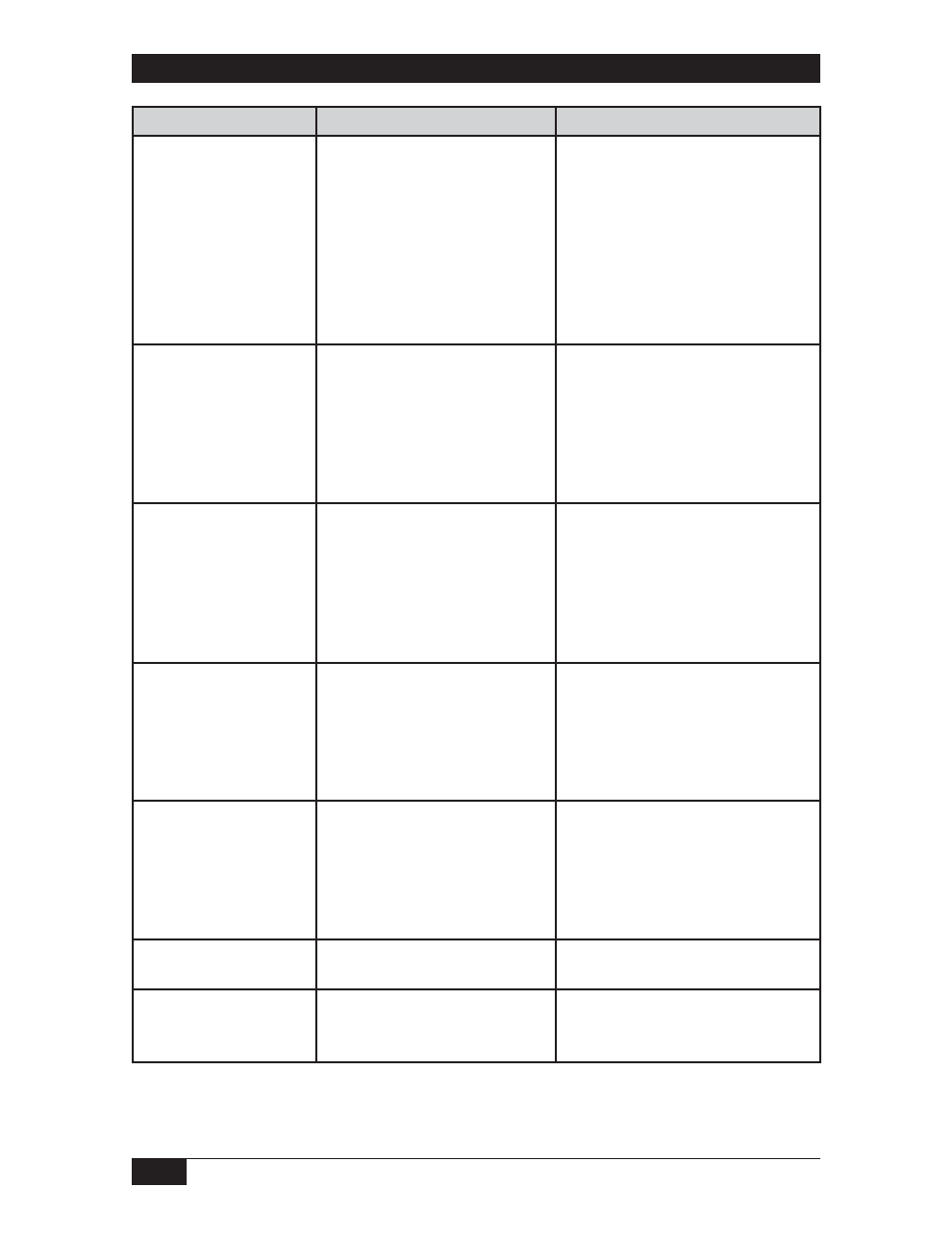

Troubleshooting

Symptom/Problem

Possible Cause

Corrective Action

LED will not illuminate,

even at maxmum

sensitivity setting (full

clockwise 25 turns)

1. Antenna banana plug loose

or disconnected.

2. No power to circuit.

3. Blown fuse.

4. Faulty sensing circuit.

1. Plug antenna banana plug

securely into sensor jack.

2. Check voltage at terminal block

as appropriate.

L1 N 95-130 VAC

L1 L2 195-250 VAC

+ - 24 + 10% VDC

+ - 12 + 1 0% VDC

3. Replace line fuses F1 and F2.

4. Replace PC board.

LED remains

illuminated, even at

minimum sensitivity

setting (full

counterclockwise

25 turns)

1. Antenna lead unplugged

and touching housing or other

ground.

2. Antenna is shorted to case

or ground.

1. Clean banana plug and insert

into sensor jack.

2. Ensure that bare end of antenna

is not touching any metal part.

Remove P1 if LED goes dark.

Clean, repair or replace sensor

assembly.

LED remains

illuminated and goes

out, but output relay

is inoperative.

1. Bad driver transistor.

2. K1 relay contact

damage.

3. Burned or broken lands

terminal feed through K1.

1. Move JP1 to other position. If

relay operates normally, replace

PC board.

2. Check condition of relay

contacts and max load of external

switched circuit.

3. Replace K1 relay or PC board.

Device will not detect

process material.

1. Sensitivity improperly set.

2. Highly conductive product.

3. Heavy conductive product

build-up on sensor.

1. Recalibrate according to

Pre-Installation I/O Test and

Calibration instructions on Page 1.

2. Use sheathed sensor.

3. Use sheathed sensor and

periodically remove build-up.

Calibration drifts

1. Widely varying dielectric due

to changing process material.

2. Highly conductive product.

3. Heavy conductive product

build-up on sensor.

1. Recalibrate according to

Pre-Installation I/O Test and

Calibration instructions on Page 1.

2. Use sheathed sensor.

3. Use sheathed sensor and

periodically remove build-up.

Corroded sensor

Process material has

chemically attacked sensor.

Use coated or sheathed sensor to

provide corrision resistance.

Eroded or abraded

sensor

Fast flowing or agitated

process has physically

attacked sensor.

Consider other sensor material

or design, relocating sensor or a

stilling well in liquid process.