Operation – Parr Instrument 6755 User Manual

Page 11

Operation

6755

3

w w w . p a r r i n s t . c o m

9

Note:

Changes to the program are made by use

of the menu structure. Any of these items can

be individually entered at any time to revise the

operating program.

Default Settings

The 6772 Calorimetric Thermometer is prepro-

grammed with default settings for use with the 1341

Plain Jacket Calorimeter. On the operating controls

page of the 6772 Thermometer is the Method of Oper-

ation key. This key toggles the thermometer between

solution and combustion calorimetry. Make sure that

the calorimeter is set to solution calorimetry. This

will force the calorimeter to restart and bring up the

appropriate set of menus and eliminate all of the keys

dedicated to combustion calorimetry.

The default values of the 6772 are designed to oper-

ate with the 1341 Plain Jacket calorimeter. Therefore,

the following parameters must be changed in the

Calorimetry Parameters menu found in the Diagnos-

tics Menu.

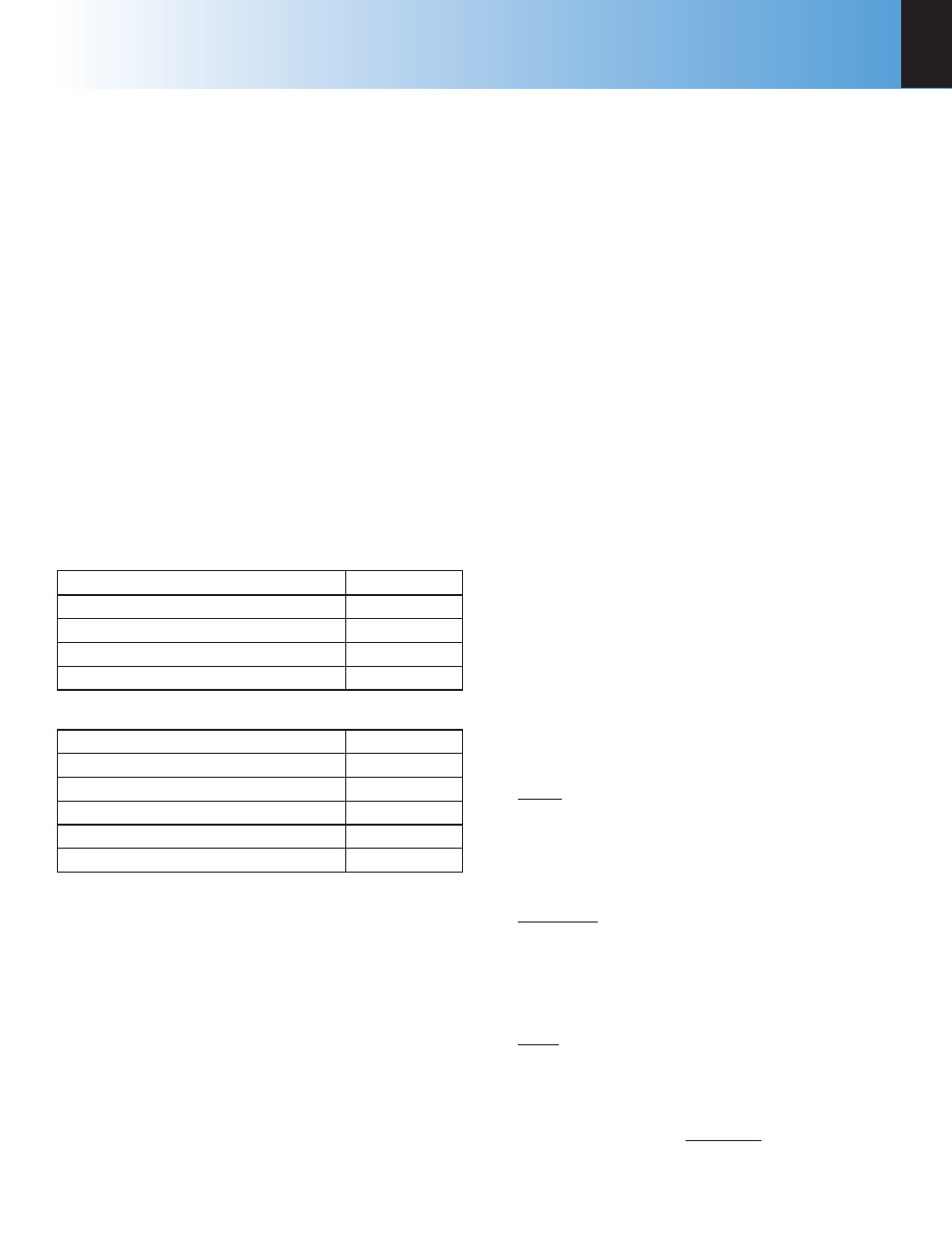

Correction (K) Parameters:

K1

0.5

K2

0.00080

K3

1.0

K4

0.0

K5

0.0

Blackout (B) Parameters:

Misfi re Blackout (B2)

72

Derivative Blackout (B3)

0.5

Dynamic Blackout (B4)

6

Equilibrium Blackout (B5)

18

Dynamic Derivative Blackout (B6)

0.02

Dynamic Time Blackout (B7)

20

Note:

To perform an endothermic run, set the

Tolerance Parameter (L2) to -1.

See Chapter 14: Default Settings for a listing of the

factory default settings. A more in-depth explanation

of these parameters is found on the corresponding

parameter group help pages. These default settings

remain in effect until changed by the user. Should

the user ever wish to return to the factory default set-

tings, go to the Program Info and Control Menu, User/

Factory Settings, touch Reload Factory Default Set-

tings and YES. Non-volatile memory is provided to

retain any and all operator initiated program changes;

even if power is interrupted or the unit is turned off.

If the unit experiences an intentional or unintentional

“Cold Restart”, the controller will return to the last

known settings.

The default parameters of the 6772 Calorimetric

Thermometer can be changed to guarantee that the

thermometer, when cold restarted, will always be in

the desired confi guration before beginning a series

of tests. Users who wish to permanently revise their

default settings may do so using the following proce-

dure:

• Establish the operating parameters to be stored

as the user default settings.

• Go to the Program Info and Control Menu, User/

Factory Settings, User Setup ID, and enter the

desired User Setup ID.

• Select Save User Default Settings

• To re-load the user default setting, go to the

Program Info and Control Page, User/Factory

Settings, Re-load User Default Settings, and YES.

Performing an Analysis

Tests can be run in a strictly manual fashion or au-

tomatically where the thermometer sequences the

calorimeter through the pre and post periods. The

manual sequencing approach is useful for applica-

tions where raw data is logged and subsequently

analyzed, off-line. In the automatic mode, the ther-

mometer fully sequences the test and applies real

time corrections to the calorimeter temperature rise

in order to correct for all systemic heat leak effects.

In either case, the operator must determine the ap-

propriate temperature source for the jacket.

• Probe – This method uses a thermistor probe

attached to the jacket wall to measure the actual

temperature of the surroundings (at the chosen

point) and the heat leak corrections are based

upon the actual differences between the bucket

and this external jacket temperature.

• Calculated – During the initial equilibrium period

this method analyzes the actual heat leak rate

and calculates the apparent temperature of the

surroundings which would generate this rate and

applies this calculated jacket temperature for the

determination.

• Fixed – In this method the operator determines

what his jacket temperature will be and enters it

into the thermometer. All heat leak corrections are

then based upon this fi xed jacket temperature.

For most applications the calculated method is rec-

ommended.