3 maintenance schedule, 8 maintenance and service – Martin Christ Epsilon 2-4 LSCplus User Manual

Page 97

Freeze-dryer EPSILON 1-4 LSCplus

Freeze-dryer EPSILON 2-4 LSCplus

8 Maintenance and service

Version 04/2014, Rev. 1.4 of 09/12/2014 • sb

97

Translation of the original operating manual

Pos: 211 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 80 Wa rtu ng u nd I nstan dhal tung /08 0-0 020 Wart ung splan Epsilon 4er @ 2 5\m od_1 404 984 679 421 _68. docx @ 18 591 6 @ 2 @ 1

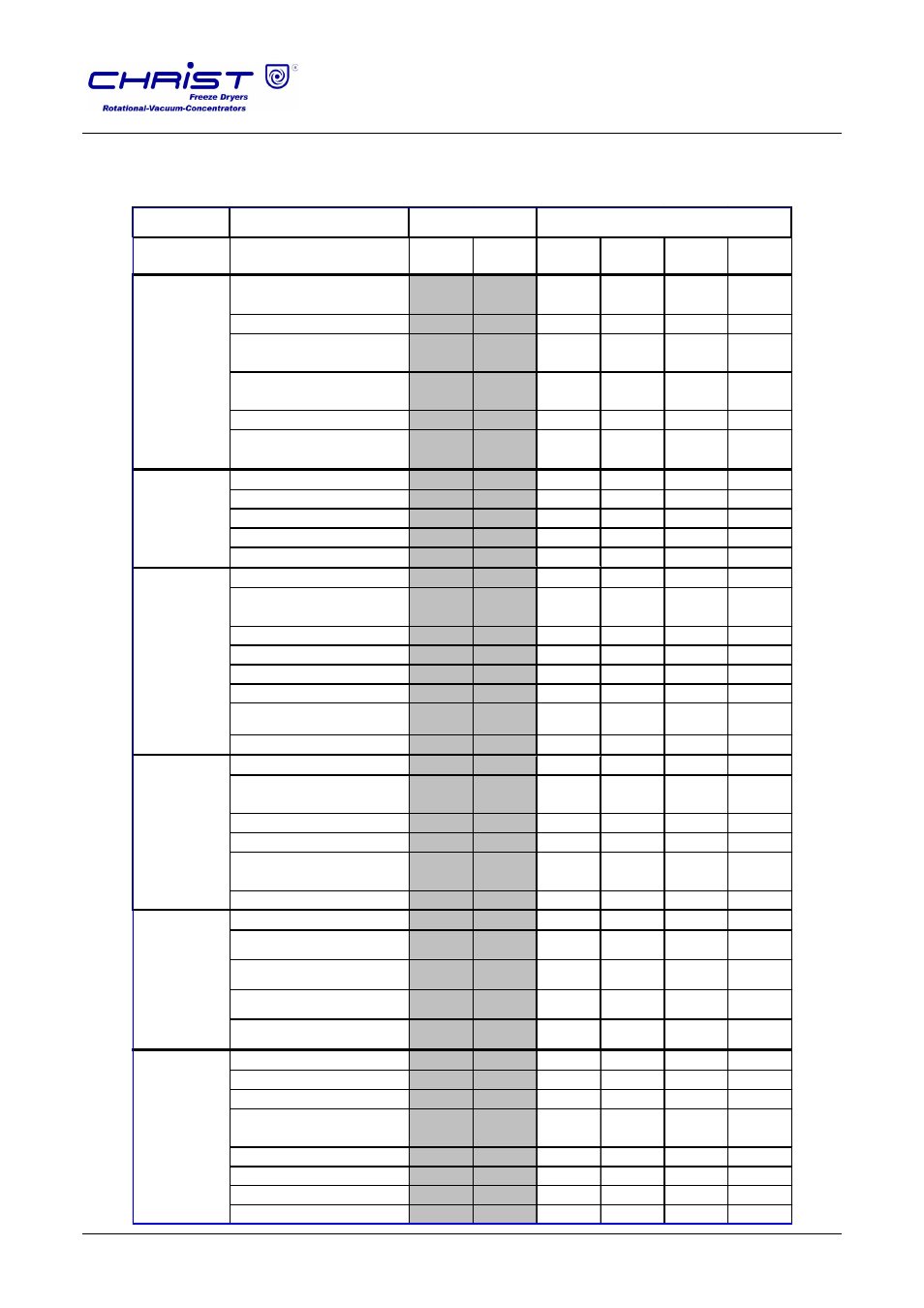

8.3 Maintenance schedule

System/

component

Detail / part

before start

daily

inspection

replace

operation

calibration

Door gasket:

clean and undamaged

X

replace

anually

Door locks, hinges: burr-free

X

X

X

Shelves:

surface clean and undamaged

X

X

Chamber door pane, sight glasses:

clean

X

X

Chamber: dry and clean

X

X

Door cover at the stainless steel

door: tight

X

Leakages

X

X

Noise emission during operation

X

X

Static seals: O-rings, clamp, KF

X

anually

Loose wire

X

Framework: corrosion

X

Pump: oil level

X

X

X

Pump: oil condition

(colour, contamination)

X

X

X

oil change

Oil mist filter: emission of oil mist

X

X

X

Oil mist filter: oil level

X

cleaning

Final vacuum of instrument

X

Residue / Particles inside oil casing

x

Oil leakages at pump

x

x

gasket after

10 years

Vacuum leakage test

X

Ice formation

X

Heat exchanger

(air cooled machine)

X

X

cleaning

Noise emission above average

X

Soleniod valves

X

Ice condenser temperature:

low end

X

Cooling water control valves

X

X

Mechanical components: function

X

Hydraulic system:

maximum pressure reading

X

Hydraulic system:

oil in reservoir

X

Hydraulic system: condition of the

hoses (oil leakages)

X

Hydraulic system:

travel speed cylinder

X

Temperature sensors

X

anually

Vacuum sensors

X

anually

Pressure sensors

X

anually

Electrical rack:

condition of the components

X

General wiring

X

Power reading of components

X

Alarm beeper

X

PLC backup battery (LSCplus)

5 years

Electrical

installation

Vial stoppering

system

Periodical maintenance

Drying chamber -

operator side

General

condition

Vacuum system

Refrigeration

system

Inspection

Pos: 212 /01 0 Univ ersal mod ule/Seit enwec hsel @ 0\m od_ 120 211 624 4312 _0. docx @ 10 5 @ @ 1