Weld termination due to secondary control, Weld termination due to a bad limit, Iq series – Dukane Ultrasonic Generator 403-575-00 User Manual

Page 96

PART

DOWNSTROKE

DOWNSTROKE

WELD TIME

WELD DIST

WELD ENERGY

HOLD

TOTAL

TOTAL

COUNT

TIME

DIST

PRESSURE 1

PRESSURE 1

PRESSURE 1

TIME

CYCLE TIME

STROKE

13

0.994

1.7916

0.038

0.0026

>>20.9

0

1.032

1.7942

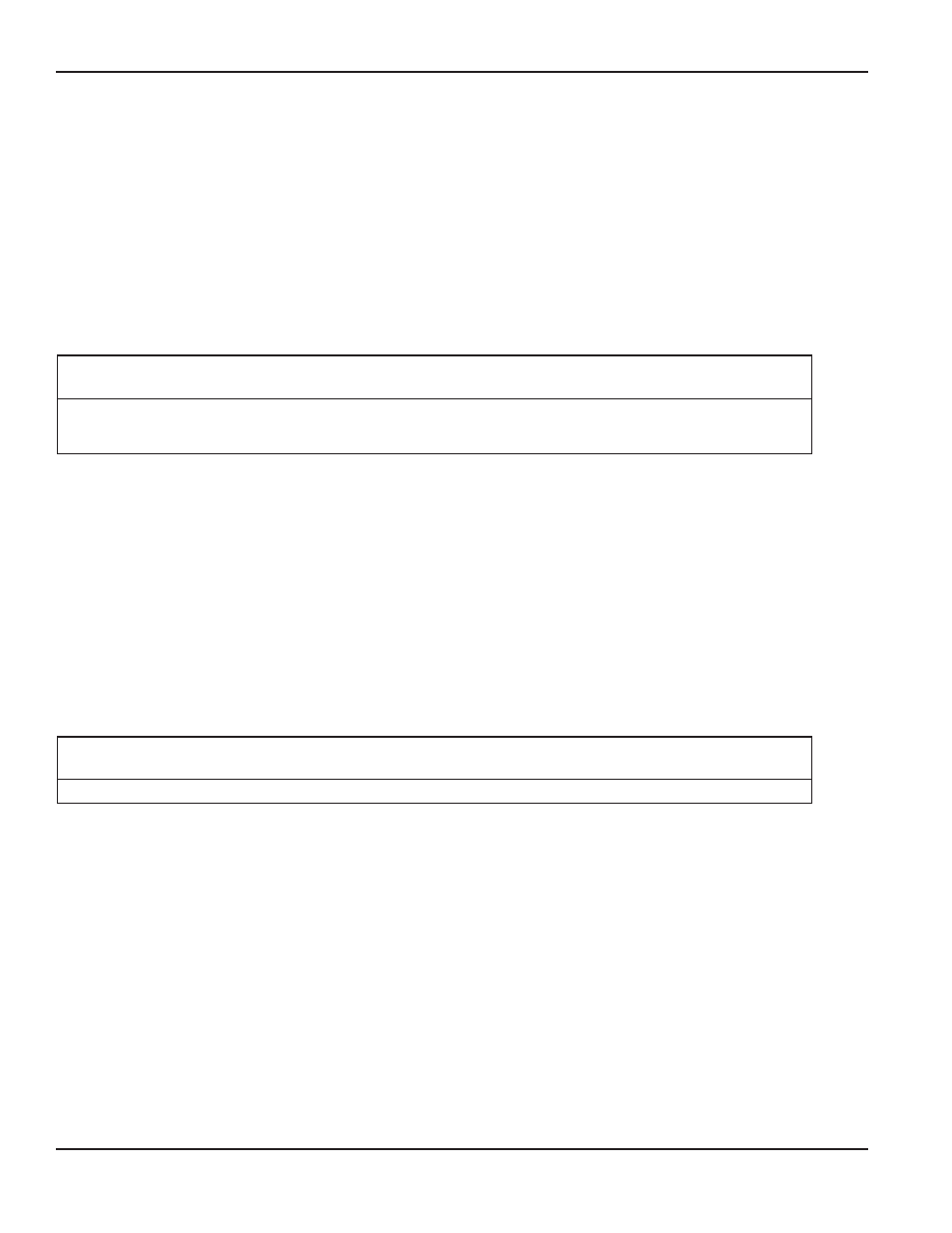

Figure 6-8

Weld Segment Terminated by a Bad Part Limit

Weld Termination Due to Secondary Control

Secondary controls are additional controls that allow the weld to be con-

trolled by more than one process parameter. In this example, the weld por-

tion of the cycle ends when either the primary control parameter (in this

case, Weld by Time for 50 ms) or the secondary control parameter (Weld

Energy for 20.0 joules) is reached. In either case, the cycle proceeds to

the hold portion of the cycle provided that no process characteristics fall

outside of the bad limits. Figure 6-7 shows the results using Weld Energy

as a secondary control.

PART

DOWNSTROKE

DOWNSTROKE

WELD TIME

WELD DIST

WELD ENERGY

HOLD

TOTAL

TOTAL

COUNT

TIME

DIST

PRESSURE 1

PRESSURE 1

PRESSURE 1

TIME

CYCLE TIME

STROKE

3

0.999

1.7915

0.037

0.0024

20.3

1.000

2.036

1.8089

4

0.944

1.7919

0.038

0.0024

20.9

1.000

1.982

1.8089

5

0.906

1.7922

0.038

0.0021

20.9

1.000

1.944

1.8090

Figure 6-7

Weld Segment Terminated by a Secondary Control

Weld Termination Due to a Bad Limit

As with all bad part limits, falling outside of a limit results in an immediate

termination of the process. Figure 6-8 illustrates the results when a bad part

limit was exceeded for Weld Energy. The two “greater than” arrows (>>)

preceding the Weld Energy measurement indicates that a bad part upper

limit was exceeded. These arrows, known as limit indicators, are always

displayed in the Cycle Data.

Page 90

iQ Series

Ultrasonic Generator/Power Supply ES User’s Manual

Dukane Manual Part No. 403-575-00