Iq servo press error messages page 2 of 2 – Dukane Ultrasonic Generator 403-575-00 User Manual

Page 89

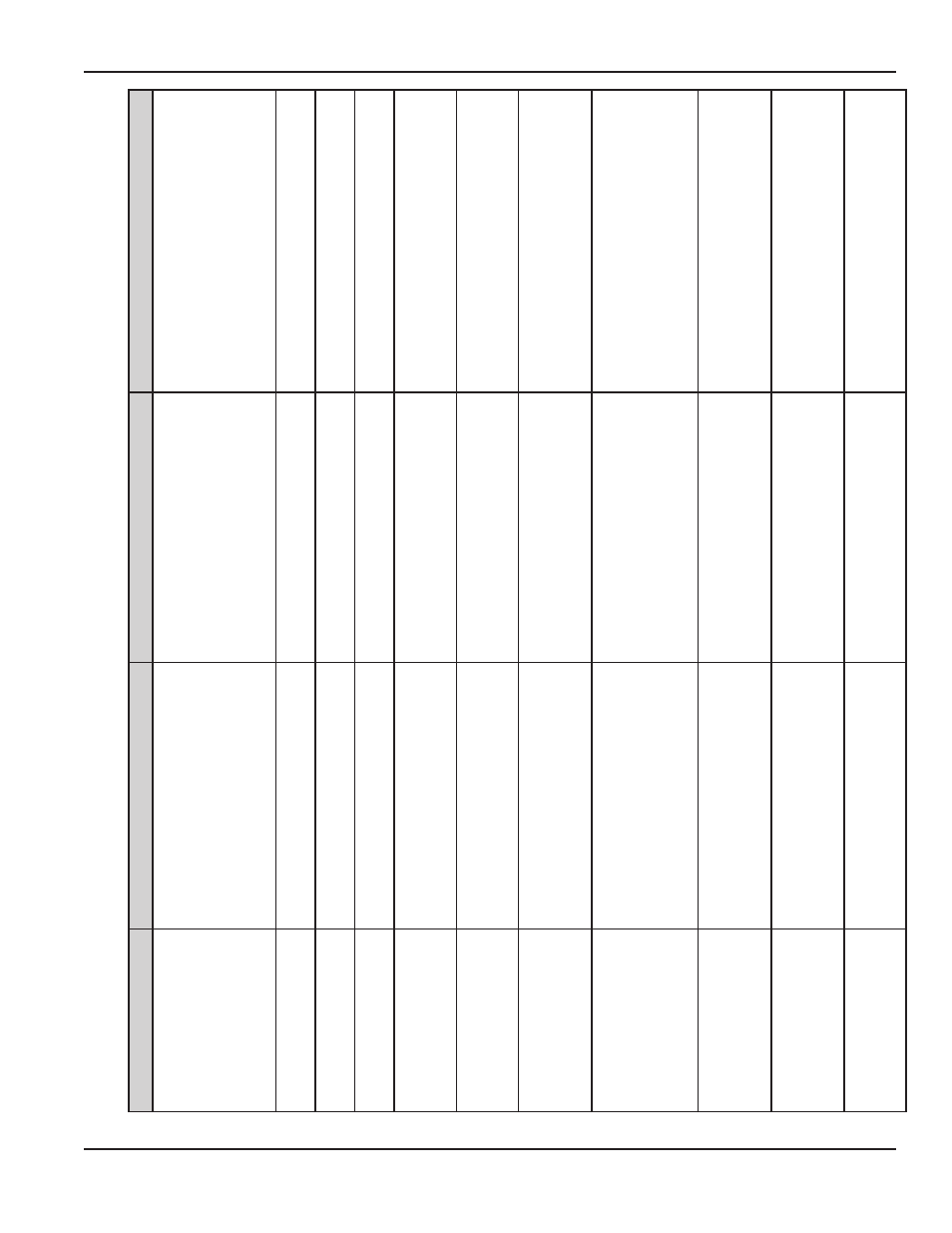

Error Message

Description

Cause(s)

Possible Solution(s)

Position Error

Allowable servo position following error was exceeded.

1. Force required to maintain pro

-

grammed speed(s) is too large. 2.

Trigger Distance or Sensing Start

Distance is too large, causing premature contact of horn with part. 3. Press motion is obstructed.

1a. Reduce weld/hold speed(s). 1b. Increase weld amplitude to increase melt rate. 2. Reduce

Trigger Distance or Sensing start

Distance. 3. Check for and remove any obstructions to press motion.

Servo Error

General servo error

.

Multiple causes possible.

1. Restart press system. 2. Contact DUKANE service.

Trigger Force or Power Trigger occurred before press reached Sensing Start Distance. 1. Sensing Start Distance is too large. 2. Part(s) not properly loaded. 1. Decrease Sensing Start Distance. 2. Check part placement. Up T ravel Limit Lower travel limit switch activated. Press moved sufficiently far up to acti - vate upper limit switch. Jog press down. Up T ravel Limit Lower travel limit switch activated Press moved sufficiently far up to activate upper limit switch. Jog press down. Overload (average) at xxx msecs. Power above generator rating. Power from ultrasonic stack sent to the part exceeds power rating of generator . 1. Excessive pressure applied to the part. 2. Booster size is too large. 1. Decrease pressure applied to part. 2. Reduce size of booster . Overload (peak) at xxx msecs. Check stack. 1. Component failure in the stack. 2. Improper stack assembly . 3. Incorrect Advanced Hardware settings. 1. Check functionality of stack components. 2. Disassemble and reassemble stack. 3. Check the generator's Advanced Hardware settings. Over temperature fault! Generator's internal temperature ex - ceeds 158º F (70º Celsius). 1. W elder duty cycle is too large. 2. W eld/hold times or forces are too large. 3. Thruster fan not working. 4. Servo actuator or amplifier is dam - aged. 1. Reduce cycle rate. 2. Change setup to reduce weld/hold forces or decrease weld duration. 3. Check if fan is obstructed; contact DUKANE service for replacement. 4. Contact DUKANE service. Overload (frequency) at xxx msecs. Check stack, cable or validate ramp up time. Generator is unable to lock to the reso - nant frequency of the ultrasonic stack. 1. Improper stack assembly . 2. Defective ultrasound cable. 3. Ramp up time is too short. 1. Disassemble and reassemble stack. 2. Replace ultrasound cable. 3. Increase ramp up time. Overload (frequency) at xxx msecs. Check for coupling between stack and part. Generator correctly locks to the resonant frequency of the ultrasonic stack, but loses the lock at a point later in the weld cycle. Horn comes in contact with the part nest or anvil. Make adjustments to thruster and part nest. Power fault. Check AC line. AC line voltage drops below 190 V AC on 240 V AC systems, and below 95 V AC on 120 V AC systems. Fluctuations in AC power . Check the incoming AC line power . iQ Servo Press Error Messages Page 2 of 2 Table 6 - I Error Messages, Servo-related (continued) Page 83 Dukane Manual Part No. 403-575-00 Section 6 - Troubleshooting