15 replacement of parts, 22 hydroblock and bypass tube – Glow-worm Ultracom sxi User Manual

Page 58

58

15 Replacement of Parts

BYPASS

TUBE

RH

HYDROBLOCK

LH

HYDROBLOCK

CH OUTLET

PIPE

SECURING

SCREW

PRIMARY

FLOW PIPE

SPIGOT (4 OFF)

MOUNTING

BRACKET

BLANKING PLATE

RUBBER SEAL

(4 OFF)

BLANKING

PLATE

AUTOMATIC

BYPASS

HOUSING

SEALS

CH FILTER

(in Hydroblock)

RETAINING

CLIP

RETAINING

CLIP

Diagram 15.17

13531

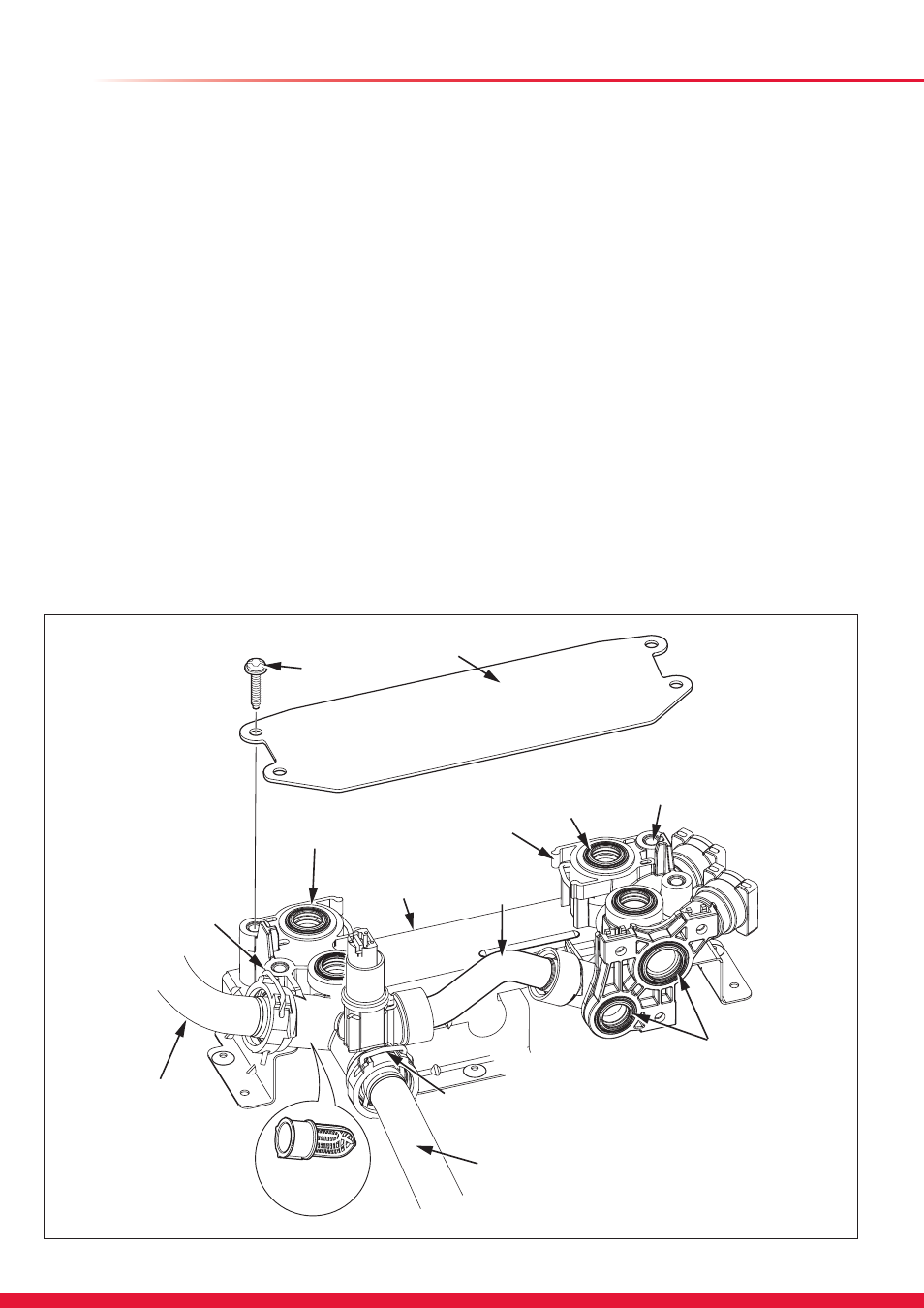

15.22 Hydroblock and Bypass Tube

For access, refer to section 15.1.

IMPORTANT: To replace the bypass tube the LH and RH

hydroblocks will need to be removed. The following procedure

must also be used for the replacement of either the LH or RH

hydroblock.

Drain the boiler heating circuit as described in the appropriate

section of 15.1.

Isolate the gas supply at the gas service isolation valve, see

diagram 12.1.

Remove the low water pressure sensor from the LH

hydroblock, refer to section 15.20.

Remove the blanking plate, see diagram 15.17.

Remove clips from the plastic LH hydroblock retaining the

primary flow pipes and CH outlet pipe, see diagram 15.17.

Remove the primary flow pipe from the LH hydroblock.

Remove the CH filter from the primary flow pipe port in the LH

hydroblock. The filter is a push-fit in the hydroblock port.

Undo the union nuts on the CH outlet pipe and gas pipe at the

connections between the top and bottom modules.

Undo the locknuts retaining the CH outlet pipe and the gas

pipe to the boiler chassis.

Rotate the gas pipe upwards and clear of the chassis panel.

Remove the 3 screws which retain the automatic bypass

housing, refer to section 15.21.

Grip the LH and RH hydroblocks simultaneously and lift clear

of the spigots on the mounting bracket. The RH hydroblock

should be drawn upwards past the plastic three way valve

body.

NOTE: Before removing the bypass tube from the

hydroblocks, take note of the tube position and orientation.

Fit the new bypass tube with new ‘O’ ring seals and re-

assemble to hydroblocks.

NOTE: Before lowering the assembly onto the bracket

spigots, ensure that the two port axis in each hydroblock run

parallel to each other and also that the bottom faces of the

hydroblocks are level and aligned.

Lower the assembly onto the bracket ensuring that the brass

washers on the DHW and DCW pipes are not displaced.

Check also that the seals on the front of the RH hydroblock

remain in place as it slides past the automatic bypass

housing. Before refitting the plate to plate heat exchanger

ensure that the four rubber seals are in place, two in the LH

and two in the RH hydroblock.

Fit new ‘O’ rings to pipes.

Refill system, vent and pressurise the boiler.