12 commissioning, 3 gas supply, 4 initial lighting – Glow-worm Ultracom sxi User Manual

Page 37: 5 check the gas inlet pressure and gas rate, Underside view of boiler

37

12 Commissioning

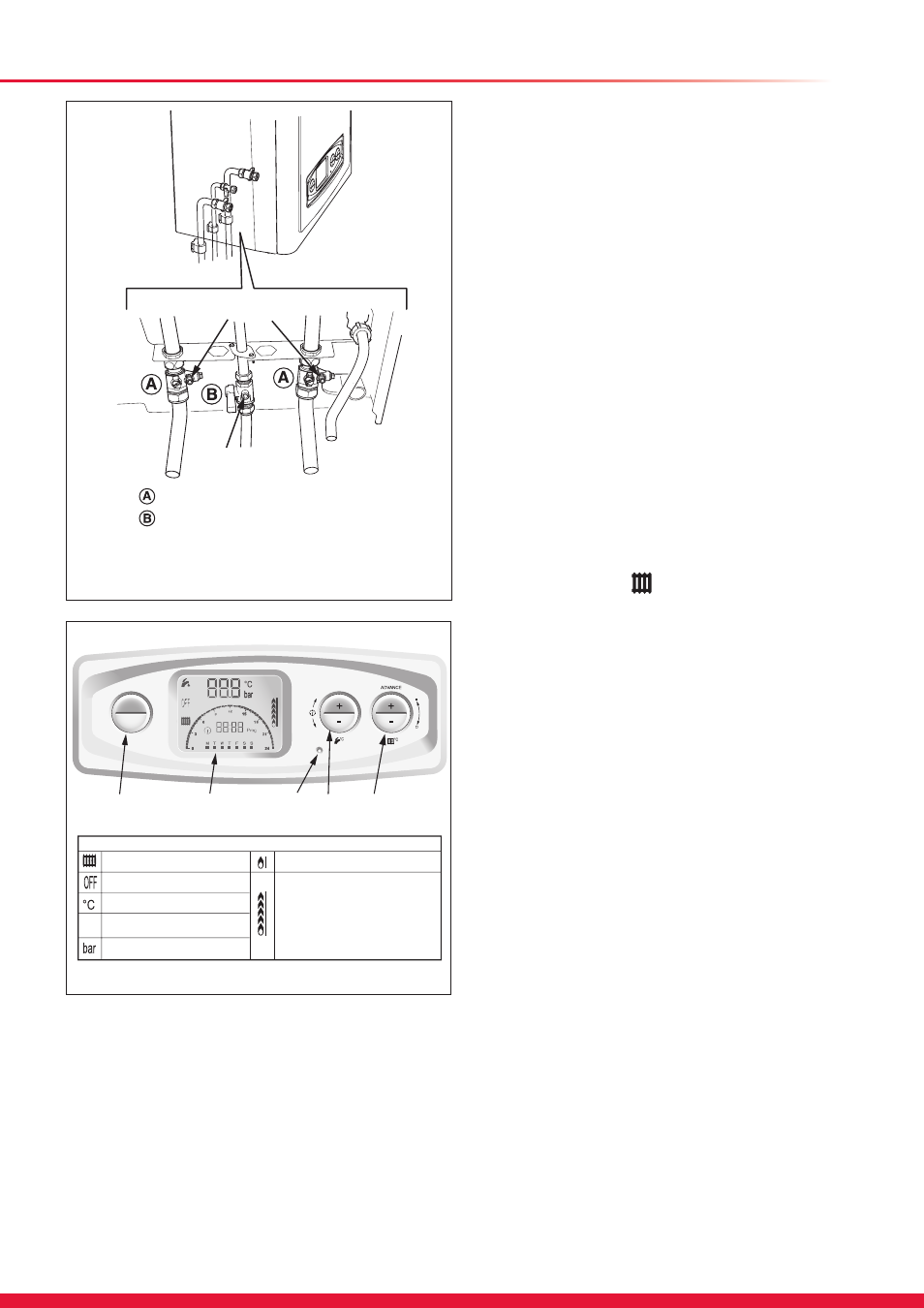

Diagram 12.1

13476

Diagram 12.2

MODE

PROG

Ext

Ext

t

SYMBOLS DISPLAYED ON THE LCD AND DESCRIPTIONS

Max burner display

Min burner display

Temperature

Appliance OFF

Central Heating Function

LCD

DISPLAY

RESET

BUTTON

NOT

USED

CH TEMPERATURE

ADJUSTMENT

TOGGLE BUTTON

MODE and PROG

Glow-worm control (Optional)

Ext

System pressure - not applicable

13473

CENTRAL HEATING ISOLATION VALVES

GAS SERVICE ISOLATION VALVE

ALL SHOWN CLOSED

DRAIN POINTS

UNDERSIDE VIEW OF BOILER

PRESSURE

TEST POINT

12.3 Gas Supply

The gas valve is factory set for natural gas (G20) and should

need no adjustment. Turn on the gas supply at the isolation

valve, see diagram 12.1. Check the supply pressure at the

pressure test point is 20mbar.

12.4 Initial Lighting

NOTE: The combustion for this appliance has been checked,

adjusted and preset at the factory for operation on natural gas

(G20) as defined on the appliance data label.

Do not adjust the Gas/Air ratio valve.

No measurement of the combustion is necessary, having

checked :

● the appliance has been installed in accordance with the

instructions.

● the integrity of the flue system and flue seals.

● the integrity of the appliance combustion circuit and

relevant seals.

● that all internal/external controls are calling for heat.

● the gas service isolation valve, diagram 12.1, is open.

As an option, a chargeable boiler only commissioning service

can be provided by Glow-worm Service by calling telephone

No. 01773 828100.

LPG Conversion: See section 12.9.

NOTE: If you have fitted a Glow-worm Options Board Kit,

please refer to the instructions supplied with the kit for

completion of commissioning.

Do not operate the boiler without water.

Refer to diagram 12.2

1. With no demand from any external controls, switch on the

electrical supply to the boiler.

Open the gas service isolation valve, see diagram 12.1.

2. Select your required function by pressing “ Mode “, scroll

through your options and select one of the following:-

Central heating.

Boiler functions ALL switched off. “OFF”

3. Turn ON your external controls and select the room

temperature required.

The boiler will operate automatically.

NOTE: The display will indicate the Heating system water

temperature or a fault code if in a fault condition.

12.5 Check the Gas Inlet Pressure and

Gas Rate

The supply from the governed meter must be of adequate

size to provide a steady inlet working pressure of 20mbar (8in

wg) at the boiler. On completion, test the gas installation for

tightness using the pressure drop method and suitable leak

detection fluid, purge as necessary.

NOTE: Due to the modulating operation of the boiler and

the need to check the gas inlet pressure and measure the

gas rate at maximum rate, it will be necessary to force it to

maximum.

Press the “reset” button on the controls fascia, release

and immediately press and hold in the “+” button. After

approximately 5 seconds “Hi” will be displayed. Pressing

the mode button when “Hi” is selected will force the boiler

to maximum rate, the display will flash between “Hi” and the

“default display” this will indicate the boiler has been forced to

maximum.

Operational Gas Inlet Pressure

With ALL other gas appliances operating, check the

operational supply pressure at the gas service isolation valve

test point, see diagram 12.1.

The nominal supply pressure for Natural Gas (G20) is 20mbar.

The nominal supply pressure for LPG (G31) is 37mbar.

Turn the taps and appliances off, then disconnect the pressure

gauge.