10 flue fitting – Glow-worm Ultracom sxi User Manual

Page 26

26

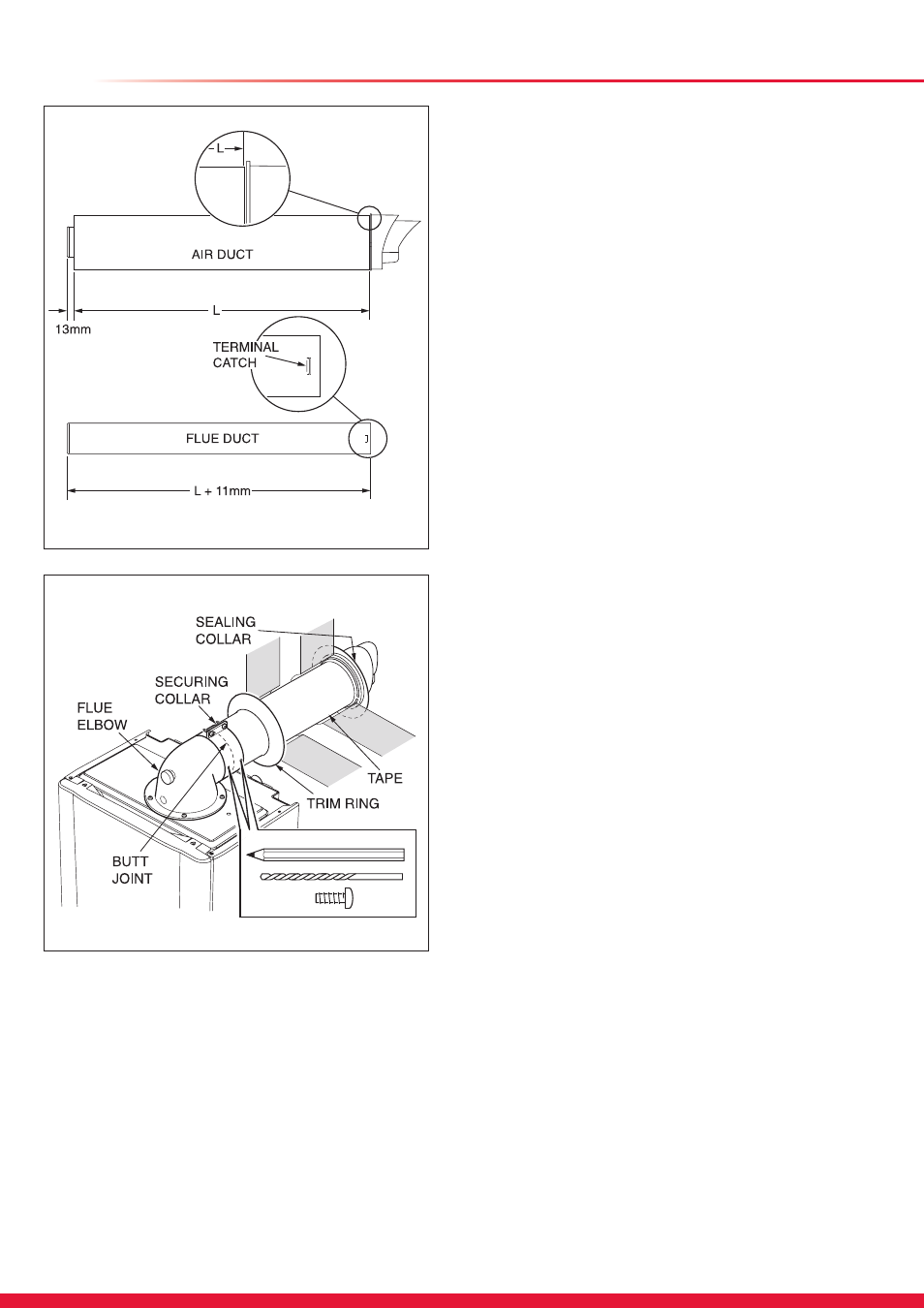

Diagram 10.16

12847

Diagram 10.17

13254

10 Standard Flue - Length, Preparation and Installation

10.10 Flue Fitting

IMPORTANT:-

The flue seals are sensitive to mineral oil based lubricants.

Do not grease the seals. If the seals do need to be

lubricated

use only water.

During the installation of the flue system, ensure that debris

such as mortar, filings or swarf are cleared from the flue

system before completion.

Long lengths of flues must be secured to the walls or ceilings

they run against. Use at least one fixing bracket for every flue

extension that is used.

After cutting inner flue tubes ensure that you de-burr and

chamfer the male tube end to prevent damage.

Inspect the flue pipes before fitting and do not install

damaged or dented flue components.

When assembling the flue system, ensure that the inner

seals are not damaged, do not install a flue component with a

damaged seal.

When fitting flue elbows ensure that they are fitted at the

correct angle to avoid strain, this will ensure that the seal fits

correctly preventing leakage.

Remove the flue elbow.

Separate the flue duct from the terminal by twisting to release

the terminal catch, then pull out of the retaining seal, refer to

diagram 10.16.

The flue duct cutting length (L + 11mm.) is shown in diagram

10.16.

The air duct should be cut at the opposite end to the terminal

The plastic flue duct MUST be cut at the opposite end to the

terminal catch.

The plastic flue duct extensions MUST be cut at the opposite

end to seal.

Insert the flue duct into the air duct terminal assembly,

remembering to engage the catch within the terminal.

Fit the sealing collar behind the locating lugs on the flue

terminal, see diagram 10.17.

Push the flue assembly into the wall, externally or internally,

initially until the end of the assembly protrudes a short way

from the inside face of the wall. This will enable the internal

trim ring (if required) to be positioned and allow the flue

assembly to be drawn back into the flue elbow.

Secure the flue elbow in position on top of the boiler with four

torque headed screws supplied.

Draw the flue assembly from wall and engage the flue duct

into the elbow and butt fit between the air duct and flue elbow.

Fit the securing collar into position.

Ensuring correct alignment of the flue, mark through two of

the pre drilled holes in the securing collar.

Remove securing collar and drill two 3mm diameter holes one

in the elbow and one in the air duct, take care not to pierce the

inner flue duct. Fit the securing collar and secure with screws

provided, see diagram 10.17.

Slide the internal trim ring back against the wall, securing in

place with a small amount of sealant if required.

NOTE: If the air and flue ducts have been correctly cut to the

instructions the sealing collar should fit flush with the outside

wall.