6 installation preparation, 7 boiler fixing – Glow-worm Ultracom sxi User Manual

Page 15

15

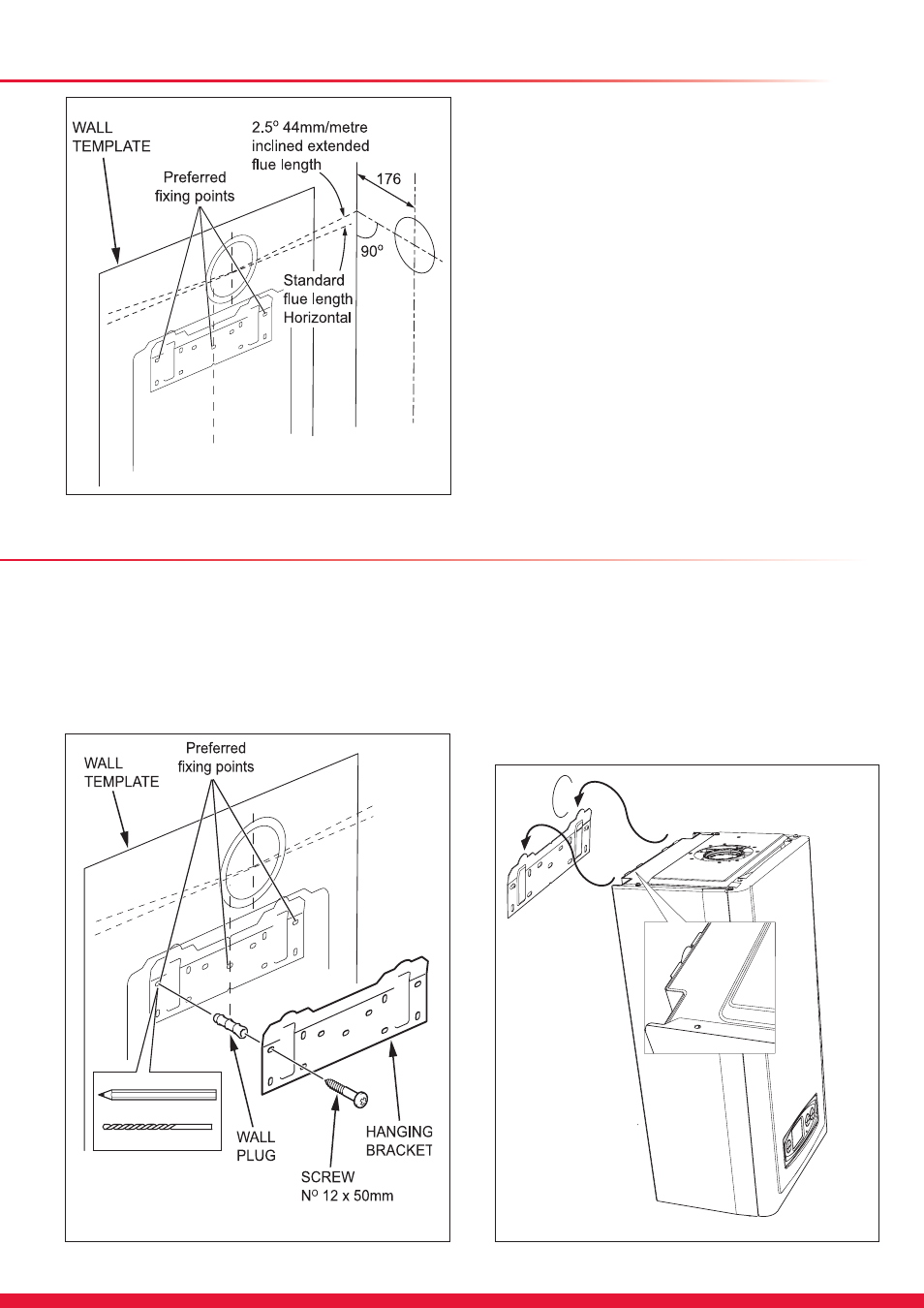

Diagram 7.1

13490

6 Installation Preparation

7.1 Hanging Bracket Fixing

The Wall Hanging Bracket is supplied in the main boiler

packaging at the rear of the boiler.

Reposition the wall template over the flue hole and mark

the position of the fixing holes for the hanging bracket, see

diagram 7.1.

Drill fixing holes and insert suitable wall plugs.

Diagram 7.2

13479

7.2 Boiler Hanging

IMPORTANT: With regards to the Manual Handling

Operations, 1992 Regulations, the following lift operation

exceeds the recommended weight for a one man lift, refer to

section 17 Manual Handling.

Lifting the boiler into position, lean the top of the boiler slightly

to the wall and position just above the hanging bracket. Lower

the boiler slowly and engage onto the hanging bracket, see

diagram 7.2.

7 Boiler Fixing

13853

Diagram 6.2

6.4 Flue Hole Cutting

External access flue installation can use a 105mm diameter

core drill.

Internal access only flue installation will need a 125mm

diameter core drill.

NOTE: The flue is designed with an internal fall of 44mm/

metre (2.5°), therefore the hole can be drilled horizontally.

If flue extension pipes are to be used then a core drill size of

125mm is required. This will allow the extension pieces to

slope at 44mm/metre (2.5°) towards the boiler.