Resistors, How are they made – Elenco Electronic Component Kit User Manual

Page 3

-2-

RESISTORS

RESISTORS,

How are they made?

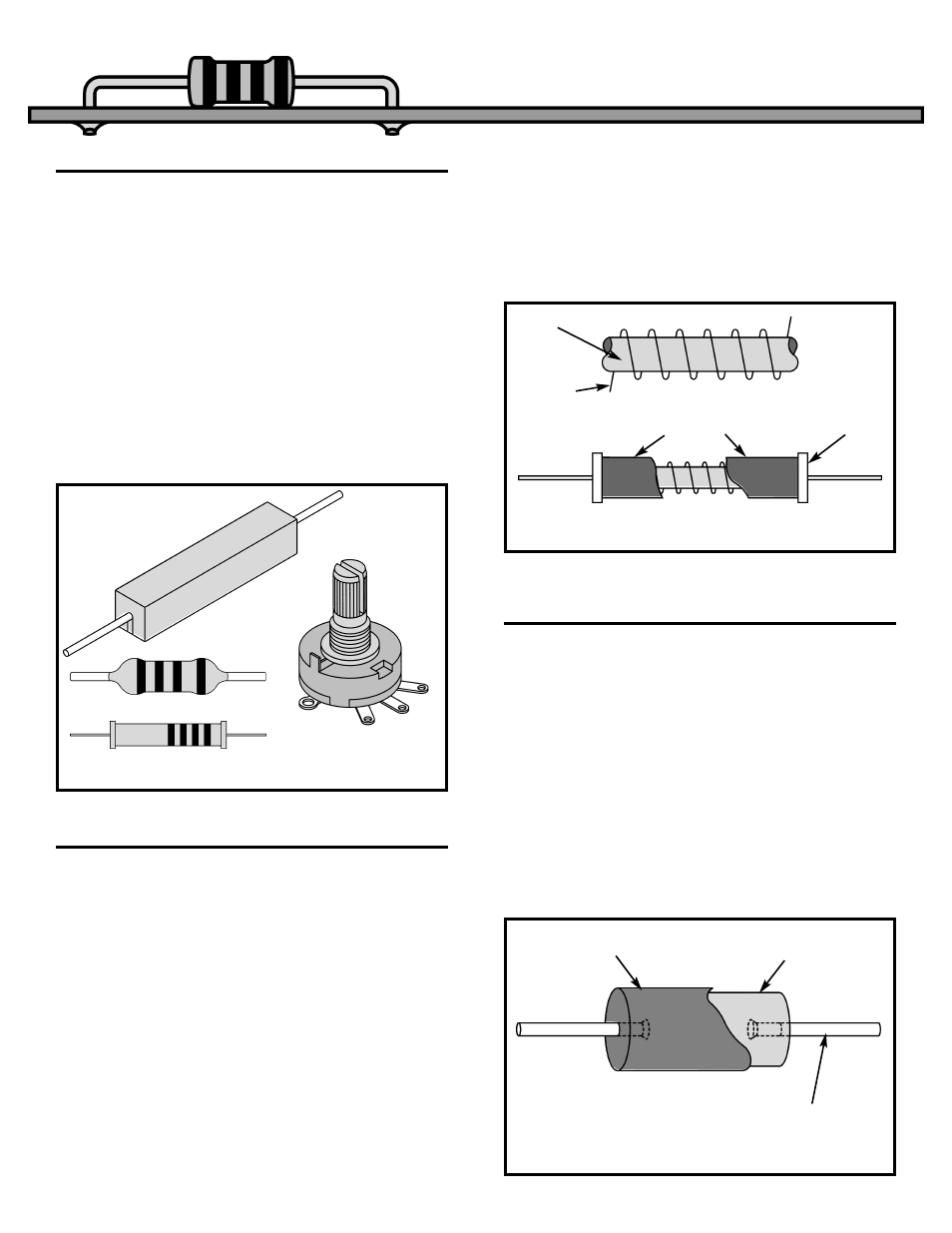

There are many different types of resistors used in

electronics. Each type is made from different

materials. Resistors are also made to handle

different amounts of electrical power. Some

resistors may change their value when voltages are

placed across them. These are called voltage

dependent resistors or

nonlinear resistors. Most

resistors are designed to change their value when

the temperature of the resistor changes. Some

resistors are also made with a control attached that

allows the user to mechanically change the

resistance. These are called variable resistors or

potentiometers. Figure 2 shows physical shapes of

some different types of resistors.

The first commercial resistors made were formed by

wrapping a resistive wire around a non-conducting

rod (see Figure 3). The rod was usually made of

some form of ceramic that had the desired heat

properties since the wires could become quite hot

during use. End caps with leads attached were then

placed over the ends of the rod making contact to

the resistive wire, usually a nickel chromium alloy.

The value of wirewound resistors remain fairly flat

with increasing temperature, but change greatly with

frequency. It is also difficult to precisely control the

value of the resistor during construction so they

must be measured and sorted after they are built.

By grinding carbon into a fine powder and mixing it

with resin, a material can be made with different

resistive values. Conductive leads are placed on

each end of a cylinder of this material and the unit is

then heated or cured in an oven. The body of the

resistor is then painted with an insulating paint to

prevent it from shorting if touched by another

component. The finished resistors are then

measured and sorted by value (Figure 4). If these

resistors are overloaded by a circuit, their resistance

will permanently decrease. It is important that the

power rating of the carbon composition resistor is

not exceeded.

Figure 2

Carbon Film

Variable

Carbon Composition

THE WIREWOUND RESISTOR

Figure 3

THE CARBON COMPOSITION RESISTOR

Ceramic Rod

Wire

End Cap

Protective Coating

Figure 4

Insulating Paint

Carbon & Resin

Mixture

Conductive Wire