Installing rpm sensors and magnets – Eagle Tree Pro, Glide, Flight and Boat Seagull Wireless Telemetry and Data Recorder User Manual

Page 6

Copyright © 2003-2010 Eagle Tree Systems, LLC

Page 6

If your system came with a temperature sensor, the dashboard is configured to display one temperature. If

you purchased additional Temperature Sensors, you will be able to monitor up to 6 temperatures with your system (two

using our loop type sensors, and up to four using our Exhaust Gas Temperature or Cylinder Head Temperature expanders).

Plug the Futaba style connector from the sensor into the recorder as shown in Figure 1.

Note: the Temperature Sensor lead can be easily extended with a standard servo extension cable.

Installing RPM Sensors and Magnets

The following instructions apply to the magnetic RPM sensor, which is included with all systems except the Glide. Note

that if you have a brushless electric motor, our easy to install Brushless RPM Sensor is also available.

Installing the RPM sensor and magnets is the most challenging part of installation, but is relatively easy once a good

mounting location is determined. Refer to our website’s support page at

http://www.eagletreesystems.com

for pictures of

example installations.

To install our magnets, first find a suitable location on your engine’s motor to attach either one or two small magnets and

RPM sensor. Typically, the prop washer or prop hub are ideal locations. This will of course vary with make and model

of aircraft. Make sure the magnets are mounted on some structure that doesn’t “flop around,” as the magnets could hit the

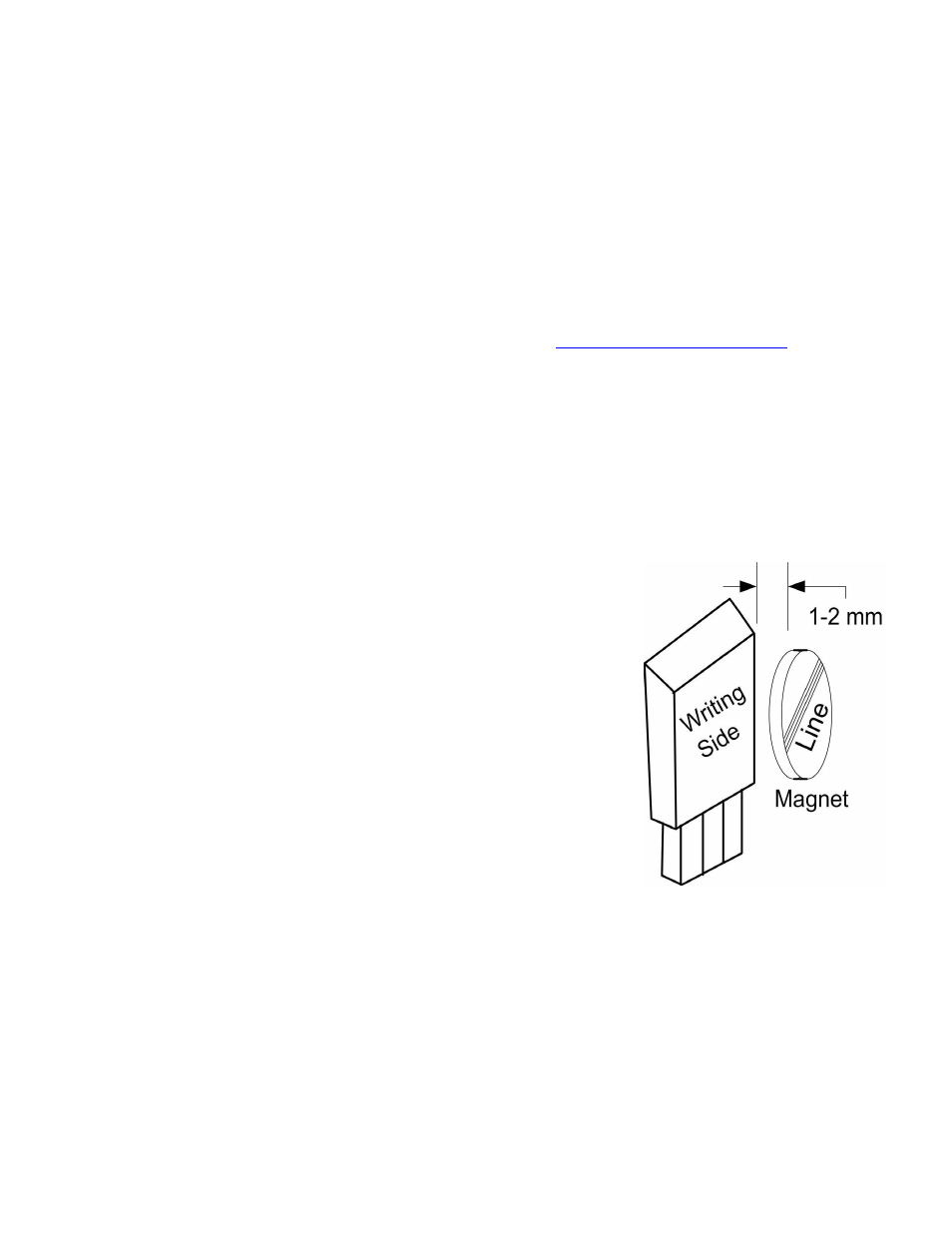

sensor in this case. The RPM sensor must be mounted so that it does not move around, and is within 1-2 mm of the two

magnets as they spin. On typical model installations, there’s usually a place where the back of the sensor can be glued to

a flat surface under or over the hub which has the magnets mounted. The Recorder kit includes four magnets. That

provides you with up to 3 spares.

Installing Magnets

Once you have determined where to install the magnets, decide whether you will

drill a hole so that the magnets will mount flush with the surface, or if you will just

glue the magnets to the surface. Though somewhat more difficult and permanent,

mounting the magnet flush with the surface is the best long term approach, since

the mounting will be much more rugged, and the risk of imbalance due to not

mounting the magnets exactly 180 degrees apart is reduced. In fact, if the magnet

is mounted flush in another metal material, it is quite possible that no shaft

imbalance will occur if you only mount one of the magnets total.

To flush mount the magnets, drill a hole just slightly larger than the diameter of the

magnet size you choose, and of the same depth as that magnet. If you decide to

surface mount the magnets, thoroughly clean this area and lightly scuff it to

improve adhesion. Glue the magnets with the side marked with a red line

facing inward (hidden), using epoxy, or other strong, suitable glue. It’s important

that the red line on the magnets faces away from the sensor once the sensor is

installed. The magnets should be glued 180 degrees apart to keep the shaft in

balance.

WARNING: make sure that the magnets are glued sufficiently so that they will not detach and create a hazard,

and always wear safety glasses when your engine is running! It is also a good idea to put a piece of heatshrink

tubing or electrical tape around the magnets, to further secure them.

Using Existing Magnets

Note: if your engine already has magnets mounted for some other purpose, there’s a good chance you can use them.

Take one of the magnets included with your recorder, and put that magnet up against the previously mounted magnet. If

the red line of the Recorder magnet faces down so that the sensor can be mounted facing the side of the magnet with no

red line, mount the sensor with the printed side toward the magnet. If the side of the magnet with the red line is visible

when on top of the previous magnet, the polarity is reversed. This should work correctly if you install our sensor

backwards (printed side of sensor away from magnets), though we have not tried it.