Carrier 38QB User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 6 — Service Data

Table 7 — Compressor Data (60 Hz)

UNIT 38QB

015

018

024

030

036

042

048; 060

R-22CHG (lb)

40

6 2

7 2

7 3

7 8

8 5

8 6

8 0

AccuRator-'-' (Bypass iypo)

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes be

fore checking charge, and after each charge

adjustment.

2. Measure suction pressure by attaching a gage to

outdoor unit suction service port. (See Fig. 6

for correct service port location on cooling cycle.)

3. Measure outdoor (coil inlet) air dry-bulb tem

perature with service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor unit.

5. Refer to correct Charging Chart. Locate on

curves where outdoor air dry-bulb and indoor

air wet-bulb temperature lines intersect.

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than chart pres

sure, add refrigerant to system until chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

Unit Single-Phase Compressors

COMPRESSORS OF THE SPLIT CAPACITOR

(PSC) TYPE require an equalized system pressure

to start. When supply voltage is within nameplate

limit and compressor does not start, give compres

sor a temporary capacitance boost. See Carrier

Standard Service Techniques Manual, Chapter 2,

for details.

Compressor Removal

— See Table 7 for com

pressor information and Fig. 7 for component

location. Shut off power to unit. Remove refrigerant

from unit using refrigerant removal methods de

scribed in Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants.

Be sure system pressure is 0 psig before

proceeding.

UNIT

38QB

V/PH

PRODUCTION COMPRESSOR

Model*

015

REK3-0125-PFV

20 1

018

CRA1-0150-PFV

51 1

024

208-230/1

MD2314GE

44

i

030

MD3214GE

44 j

036

MD3514GE

44 1

042

PC4616BD

64

048

230/1

PC5016BD

64 1

060

PC6016BD

64 1

036

MF3513GE

44

042

048

208-230/3

PY4616AD

PY5016BD

64

64

060

PY6016BF

64 1

036

MH3513GE

44 i

042

460/3

PH4616AD

64 !

048

PH5016BD

64

060

PH6016BF

64

Oil Recharge

Ounces

‘Refer to Service Parts Catalog for replacement compressor

model numbers

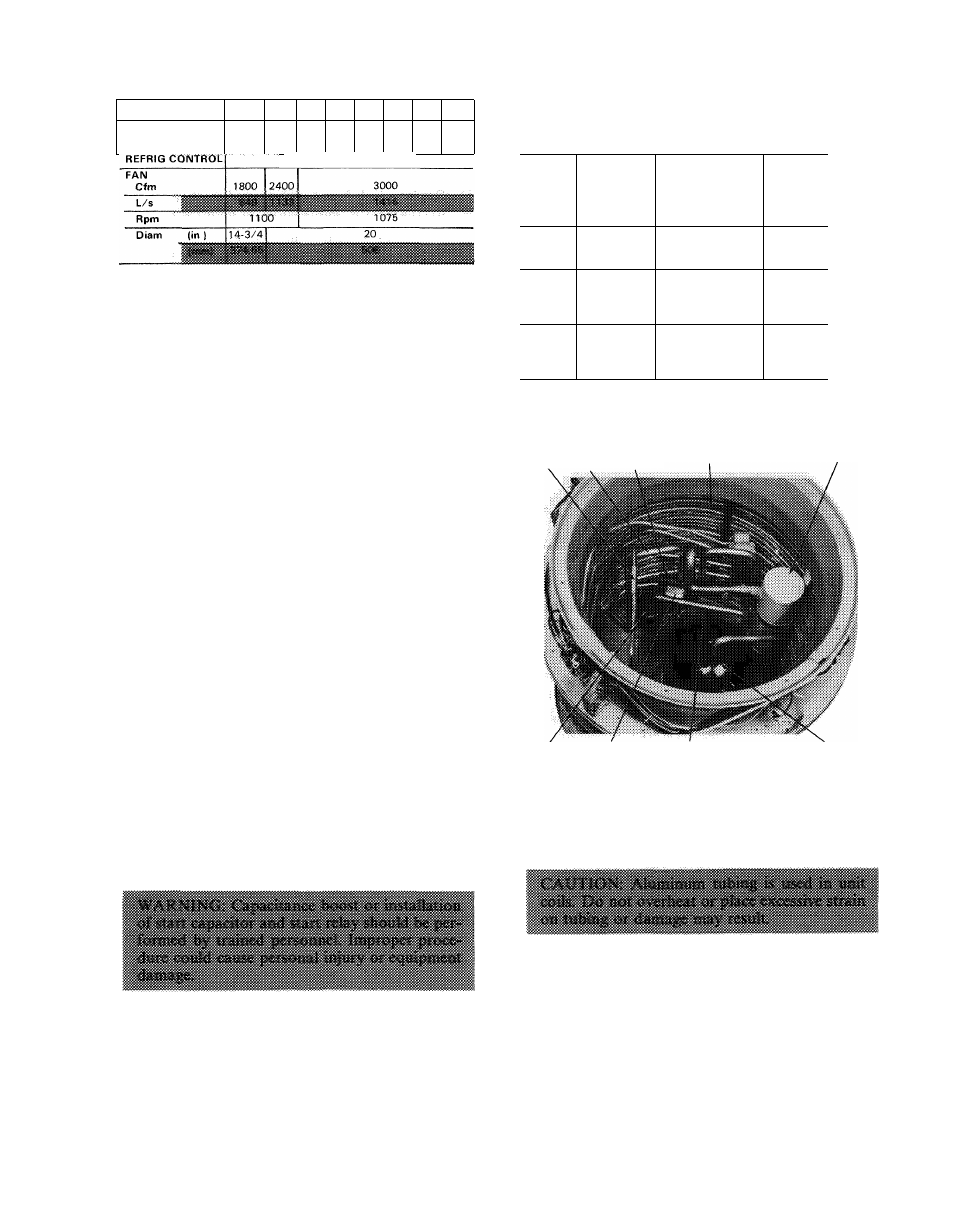

STRAINER VAPOR REVERSING

LINE VALVE

ECOIL

ACCUMULATOR

MUFFLER SOLENOID

HOT GAS

COIL

DISCHARGE LINE

COMPRESSOR

Fig. 7 — Component Location

Follow safety codes. Wear safety glasses and

work gloves. Have quenching cloth available.

1. Remove top cover as described in Installation,

Step 1.

2. Disconnect high- and low-voltage field wiring

and fan motor leads from capacitor and

contactor.

3. Remove screws holding discharge grille in place.

Lift grille from unit.

4. Disconnect compressor leads (crankcase heater,

low-pressure switch, defrost thermostat and

solenoid coil) from electrical components and

pull them thru the wire access opening into the