Table 1 — carrier approve^^6^ systems, Step 2 — mount outdoor heat pump, Step 3 — make piping connections – Carrier 38QB User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

^ Table 1 — Carrier Approve^^6^ Systems

OUTDOOR

UNIT

38QB

REQUIRED

OUTDOOR

PISTON

SIZE

INDOOR

UNIT

MODEL 8i

SIZE

REQUIRED

INDOOR

PISTON

SIZE

015

38

28HQ.VQ018

40AQ018

46

40DQ018

46*

018

42

28HQ.VQ024

40AQ024

40DQ024

52*

28HQ.VQ024

55

40AQ024

55*

024

46

40DQ024

59

28HQ.VQ030

40AQ030

40DQ030

61*

28HQ.VQ030

63

40AQ030

63*

030

59

40DQ030

63

28HQ.VQ036

40AQ036

40FS160 1 28HQ.VQ036

70*

036

61

28HQ.VQ036

40AQ036

40FS160 1 28HQ.VQ036

67

28HQ.VQ042

40FS160 1 28HQ.VQ042

40QB.QH042

76

042

63

28HQ.VQ042

40FS160 I 28HQ,VQ042

40QB.QH042

76

048

73

28HQ.VQ048

40FS200 1 28HQ.VQ048

40QB.QH048

86*

060

82

40QB.QH060

93

‘Replace factory-installed piston with this piston size

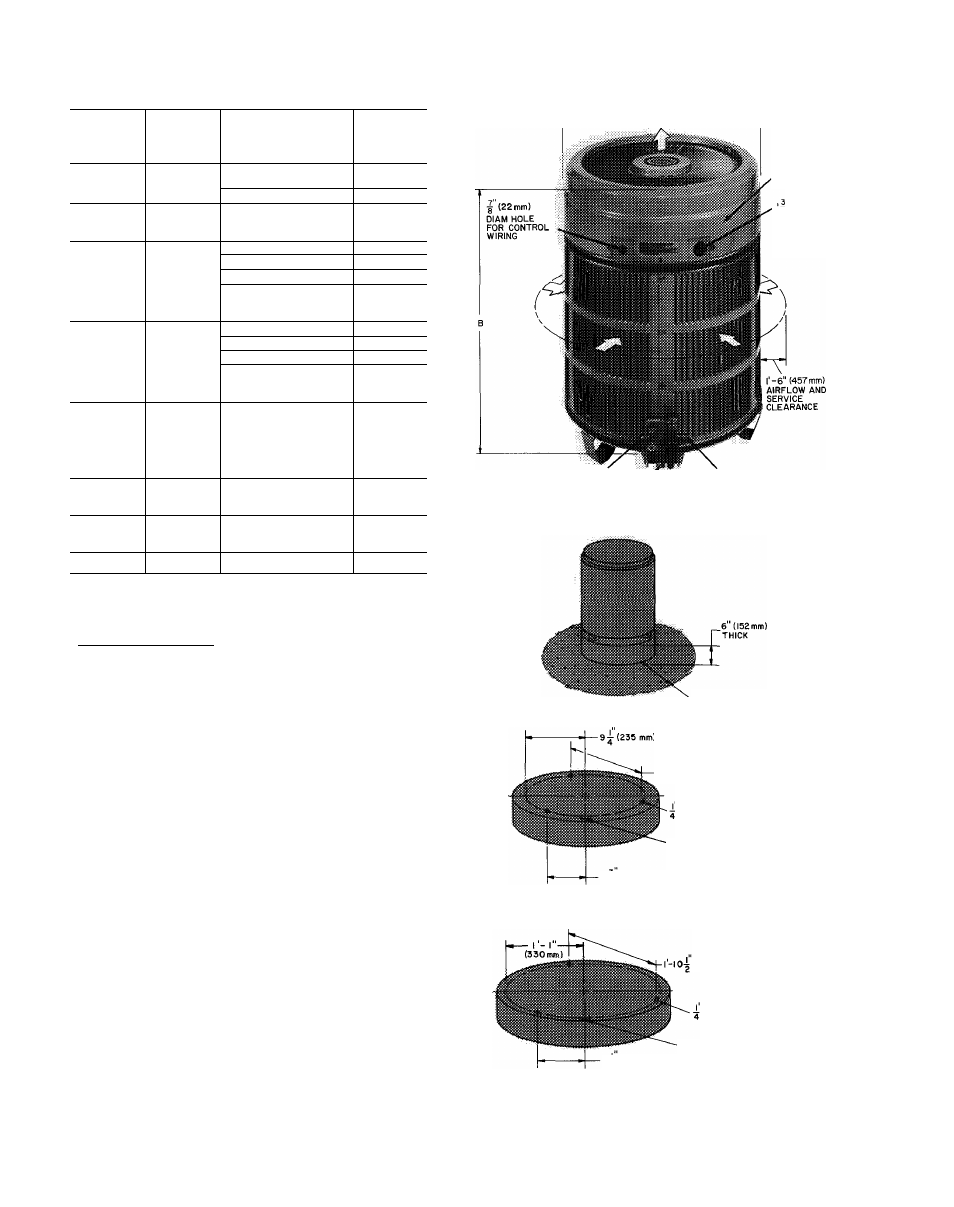

Top Cover Removal — Top cover can be removed

for wiring or servicing heat pump. Loosen decora

tive strip and slide down off screw heads. Remove

3 screws in connector plate and 2 screws on front of

unit. Loosen remaining 4 serews. Lift top from unit

(see Fig. 1).

Step 2 — Mount Outdoor Heat Pump

ON THE GROUND: MOUNT ON A SOLID

LEVEL CONCRETE PAD (see Fig. 1). Swing 3

legs down and lock in position, except when using

accessory rack. Use accessory heat pump rack

(Fig. 2) in areas where prolonged subfreezing tem

peratures or heavy snow occur. (Refer to installation

instructions included with rack.) Drainage holes in

unit base must not be obstructed.

ON THE ROOF; MOUNT ON A LEVEL PLAT

FORM OR FRAME. Proper precaution must be

taken for support of unit in roof design. Elevate unit

for proper clearance as described under ground

installation, above. Plan roof design and water

drainage to prevent unit from setting in water. Flash

all roof openings to prevent leaks.

Roof mounted units exposed to winds above

5 mph (8 km/h) may require protective wind baffles

(field fabricated) to achieve adequate defrost.

Step 3 — Make Piping Connections

— Heat

pumps may be eonneeted to indoor sections using

Carrier aecessory tubing package (Table 3) or field-

supplied tubing of refrigerant grade, correct size and

4'-0" (1220 mm) OVERHEAD SPACE REQUIRED

FOR SERVICE AND AIRFLOW

TOP

COVER

DIAM HOLE

FOR POWER

WIRING

I

LIQUID VALVE SERVICE PORT

f

VAPOR VALVE SERVICE PORT

[//> AIRFLOW

SUCTION SERVICE PORT

12 (305mm)

GRAVEL APRON

I-4 (407mm) TYPICAL 3 PLACES

(6.35 mm) TIEDOWN BOLTS

CENTERLINE BETWEEN

VALVES

6^ (172 mm)

Г-н" (585mm) DIAM x 6"(l52mm)THK CONCRETE

MOUNTING PAD FOR 38QB0I5

(572 mm) TYPICAL 3 PLACES

(6.35 mm) TIEDOWN BOLTS

CENTERLINE BETWEEN

VALVES

9^ (241 mm)

2-6" (762 mm) DIAM x 6" (152mm) THK CONCRETE

MOUNTING PAD FOR 38QB0i8-060

Fig. 1 — Dimensions, Connections and

Mounting Pad (Refer to Table 2.)