4it ip, I-ì4, Pumpdown procedure – Carrier 38QB User Manual

Page 14: Unit controls and safety devices, Table 8 — pressure switch settings

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

360

(2482)

340

(2344)

3

300

> (2069)

01

a

S

280

5 (1931)

!;

I 260

« (1793)

240

(1655)

220

(1517)

ÌFH

-r^

. ;TT

: (li

4 ì it

-4 f4-

rii^

P 62 F

pi (I6.6C)

Pi

:|T|C =•1^1=2

000:

til

i-PP-

■ j f!

p| i4

ri ;J

w

P H

liii- iiO

Pi

tp

1 u t

: 1 ! . II5F 4P;

tp.

P

h

ET-

NT IN

i-iiL

3ULB

DOOF

TrPF(46.l(

TEMPAIR

p:[

UT

itlp

;jj E

UNIT

1 P i | P : i

• 1 r i

M i !

4it ip

t-pt

05 F

pii

iPr

T-i ¡J-

'P';

h: :p i-y (4 O.bC ) /

RT

pp-ip-

JP

'Hi-

-Hip

l:.i±r

44-

-i/-

iH-p

Ìpi;

:[n

i|4

1 i -

-7;

-PI

96F

350

"7

ii:i-

P

l

/ i -

1 ,

;

:

! : :

t

TTtt

tr

Pi-

f-r:

f

i_!_;

Fi" ” PI

44

p4

ijtr Ì:I

t

r 85 F

i (29.4 C)

44:

l'r :

44-4 4

pH;

fip

■PP

T

/. :

S

44

ÌÌ4

i-Ì4#

t/ ■

Cil:

j

pi

iP

'-'

t

P : ; 1 .

LI ■ :

iitt

tm

-jfiP

P;

l

2lii ip-

ì

4H-

ì

S

l

ifii

■fljH

ljp

PII

PSIG

(kPa)

64

(441)

68

(469)

72

(496)

76

(524)

80

(552)

PRESSURE AT SUCTION SERVICE VALVE

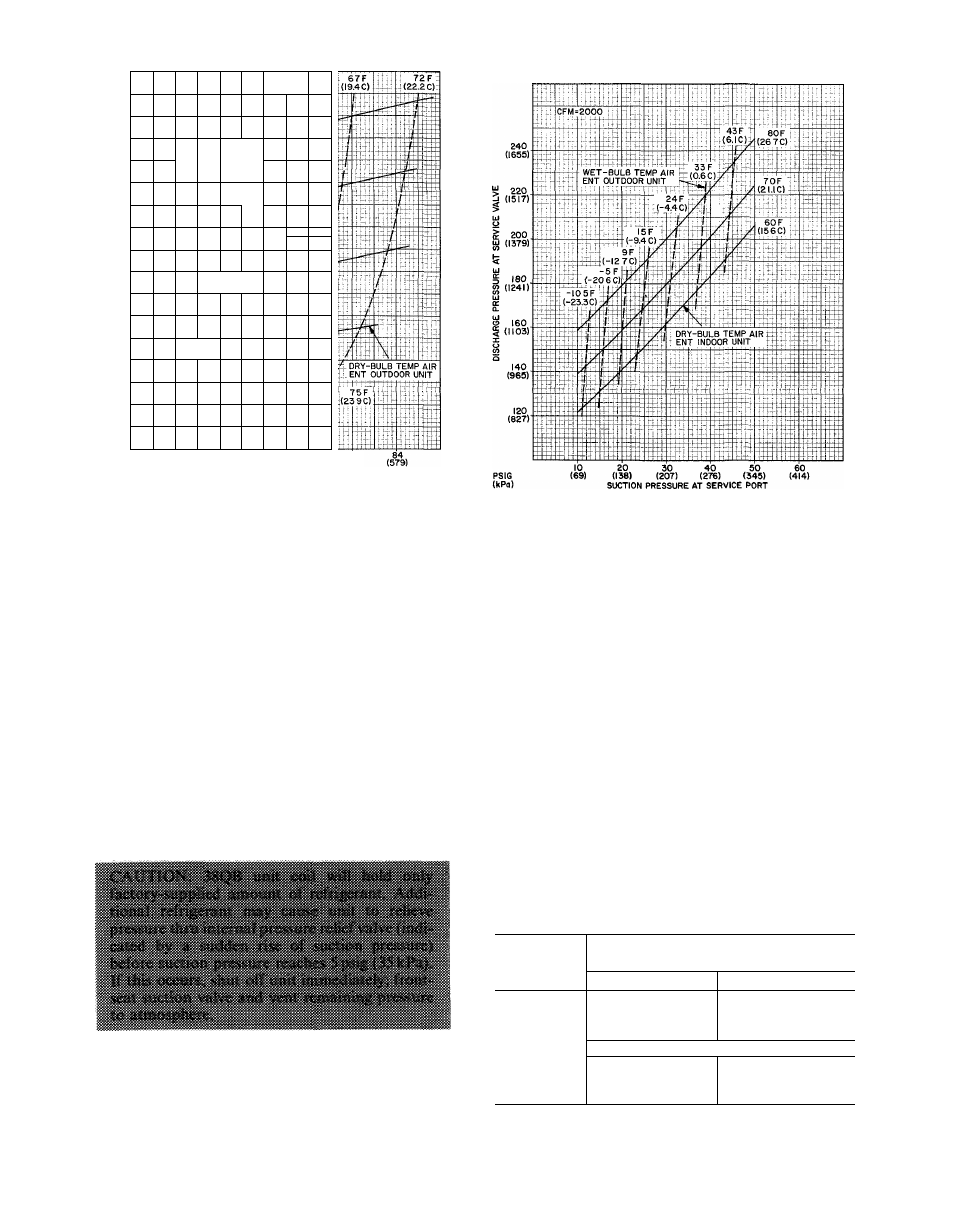

Fig. 22 — 38QB060 with 40QB,QH060

Cooling Cycle Charging Chart

Fig. 23 — 38QB060 with 40QB.QH060

Heating Cycle Operation Check Chart

Filter Drier

— Install field-supplied filter drier

(Table 3) in system liquid line when refrigerant sys

tem is opened for service as described under Com

pressor Removal. Position drier in liquid line at

convenient location.

Pumpdown Procedure

— The system may be

pumped down in order to make repairs on low side

without losing complete refrigerant charge.

1. Attach pressure gage to suction service valve

gage port.

2. Frontseat the liquid line valve.

3. Start unit and run until suction pressure reaches

5 psig (35 kPa) (see Caution).

4. Shut unit off and frontseat suction valve.

5. Vent remaining pressure to atmosphere.

Unit Controls and Safety Devices

HIGH-PRESSURE RELIEF VALVE is located in

compressor. Relief valve opens at a pressure differ

ential of approximately 500 psig (3448 kPa) between

suction (low side) and discharge (high side) to allow

pressure equalization.

INTERNAL CURRENT AND TEMPERATURE

SENSITIVE OVERLOAD resets automatically

when internal compressor motor temperature drops

to a safe level (overloads may require up to 45

minutes to reset). When an internal overload is

suspected of being open, check by using an ohm-

meter or continuity tester. If necessary, refer to

Carrier Standard Service Techniques Manual,

Chapter 2, for complete instructions.

LIQUID

LINE

LOW-PRESSURE

SWITCH

(LLPS) is connected in liquid line to work with

compressor internal thermostat in providing loss-of-

charge protection during the heating cycle. Control

is mounted on liquid line.

With a high-side leak, pressure gradually de

creases until low-pressure control stops the com

pressor. (Low-pressure control settings are shown

in Table 8.)

Table 8 — Pressure Switch Settings

UNIT

38QB

LIQUID LINE

LOW-PRESSURE SWITCH

Cut-in

Cutout

015

018

024

030

2 2 +

5t)sis

7

±

3 psio

036

042

048

060

14