In-line impeller design, Flash and thermal economizer, Thermal purge – Carrier 19 Series User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

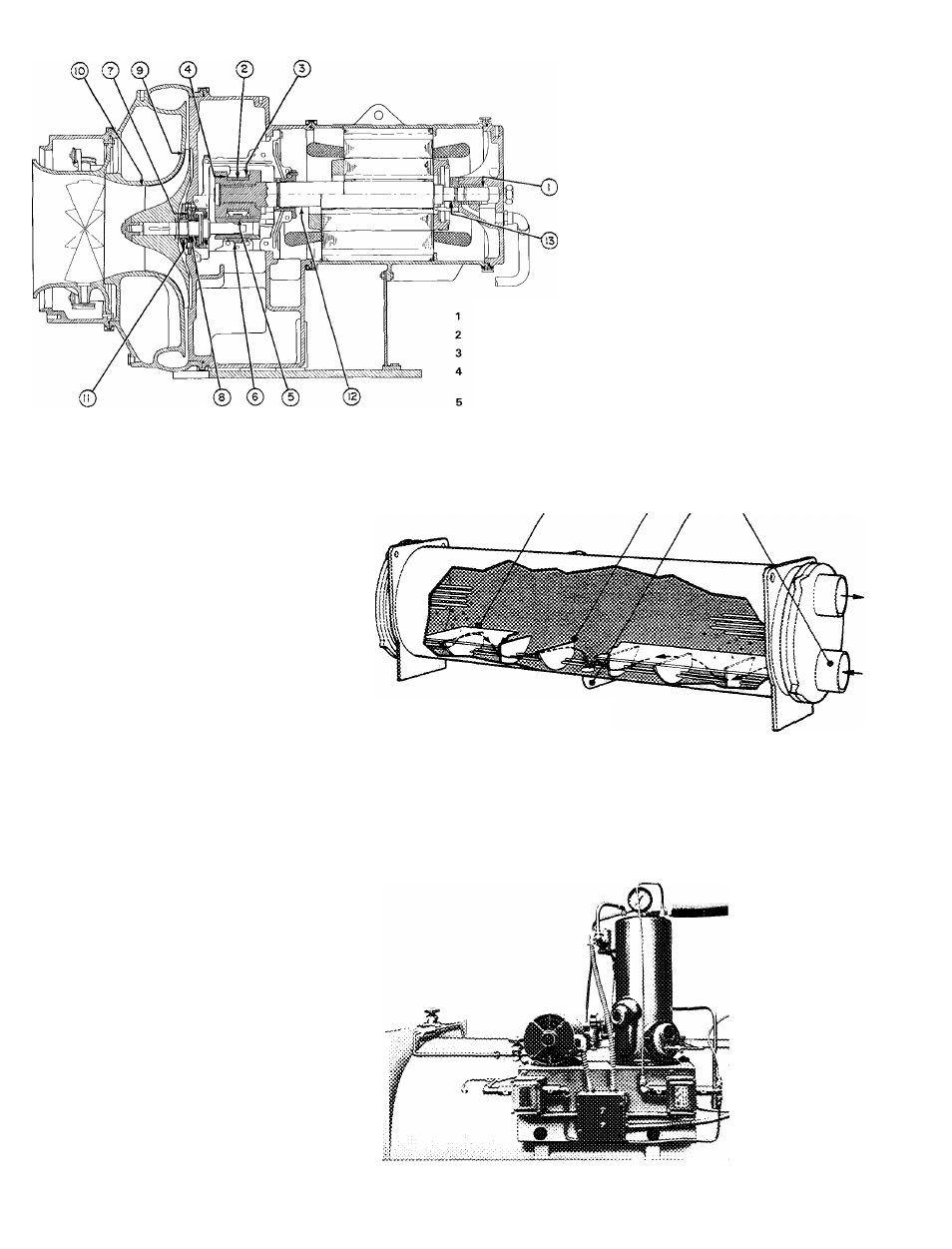

In-line impeller design

In-line impeller design, with diaphragm

between stages, allows for more flexi

bility in compressor component selec

tion, which results in first cost savings

on other machine components. Also

provides higher head capabilities, pre

vents uneven loading and allows for

routine, easy maintenance.

LEGEND

19DH

Flash and thermal economizer

Two-stage models thru 1,600 ton

(5627 kW) capacity feature a thermal

economizer. The thermal economizer

shown brings warm condensed refriger

ant into contact with the inlet (coldest)

water tubes where water as low as 55 F

(13 C) may be flowing. This low tem

perature water subcools the refrigerant

so when it moves on in the cycle it

has greater cooling potential, thus im

proving cycle efficiency and reducing

power/ton requirements. In addition, all

two-stage models employ a flash econo

mizer, not shown, to further improve

cycle efficiency. The liquefied refrig

erant leaves the condenser thru a

metering device and flows into the flash

economizer where the normal flashing

of part of the refrigerant into vapor is

used to cool the remaining refrigerant.

The flash vapor is diverted directly to

— Motor End Bearing

8

— High-Speed Journal Bearing

— Gear Journal Bearing

9

— Front of Impeller to Volute Wall

— Driving Gear Bearing To Housing

10

— Impeller Eye to ID of Inlet Ring

— Thrust Clearance on Gear

Bearing (each side)

11

— Labyrinth Behind Impeller to

Spacer Ring

— Pinion Gear Journal Bearing

— Pinion Gear Bearing To Housing

12

— Labyrinth Behind Transmission

and Motor Shell

— Thrust Bearing

13

— End-Bell Bearing Labyrinth

14 *5

J6 17

19FA THERMAL ECONOMIZER

the compressor’s second stage so that it

does not have to be pumped thru the full

compression cycle. The flash econo

mizer generates savings and signifi

cantly lowers operating costs.

LEGEND

14

— Thermal Economizer Partition Plate

15

— Refrigerant Flow Baffle

16

— Refrigerant Liquid Drain Line

17

— Condenser Water Inlet

Thermal purge

The thermal purge effectively removes

air, water, and noncondensables from

the refrigerant system, promoting

greater operating efficiency and lower

maintenance costs. It needs no water

connections or air-cooled condenser.

It performs normal system purging

during periods of operation on R-11 and

R-114 machines. In addition, on R-11

machines it doubles as a pump for leak

testing or machine evacuation after

servicing. It also provides recovery of

refrigerant

under

normal

purging

conditions.

19DH