Controls, Control system – Carrier 19 Series User Manual

Page 43

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

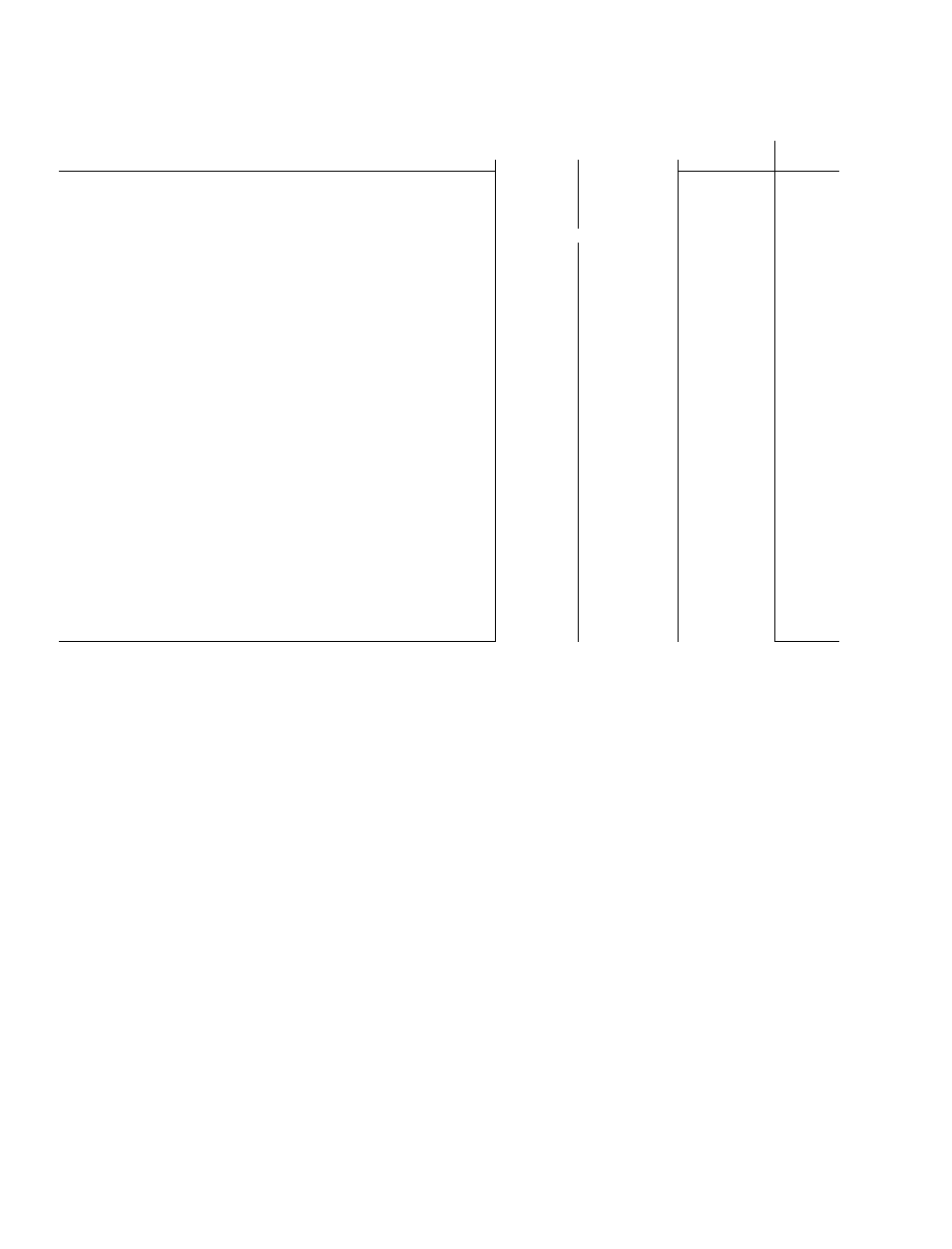

Controls

SAFETY AND CONTROL COMPONENT FEATURES

FEATURE

APPLIES TO THE

19DH

19EB

19FA

19CB

SAFETY CUTOUTS:

Bearing High Temperature

.

*

*

*

Motor High Temperature

*

*

*

♦

Gas Discharge High Temperature

—

*

*

—

Refrigerant High Pressure (Condenser)

*

*

*

*

Refrigerant Low Pressure (Cooler)

—

*

—

—

Refrigerant Low Temperature (Cooler)

*

—

*

y

Oil Pump Motor Overload

*

\/

Lube Oil Low Pressure

*

*•

*

*

Impeller Displacement Limit

—

*

*

Cooler and Condenser Water Flow Switches

/

y

\/

Y

INTERLOCKS:

Unloaded (Vanes Closed) Start

*

*

*

Pre-Lube and Post-Lube (via Program Timer)

*

*

*

*

Starting Sequence (via Program Timer)

*

*

*

*

Low Chilled Water Temp/Recycle Sequence (via Program Timer)

*

*

*

*

Oil Cooler Water Flow (Solenoid)

*

*

*

*

Machine Manual Reset after Safety Cutout

*

*

*

CAPACITY CONTROL:

Guide Vane Actuator

*

*

*

*

Solid State Leaving Chilled Water Control

*

*

*

*

Motor Current (demand) Limit — Adjustable 40-100%

*

*

*

*

Manual Leaving Chilled Water Reset

*

*

*

*

OTHERS:

Elapsed Time Indicator

*

*

*

*

Start Counter

*

*

*

—

Manual (Local) Start

*

*

*

Auto. (Remote) Start

#

#

#

#

Pneumatic Leaving Chilled Water Control

—

—

#

#

Pneumatic LCW Control Transducer

#

n

—

—

Safety Indicator panel

#

#

#

tl

Lead-Lag Panel

#

#

#

n

Mounted Oil Pump Starter

*

*

/

y

^Factory supplied and installed

/ Required — Field- and/or Factory-Option Supplied

#Optional

— Not applicable to this unit

Control system

The safety controls of each Carrier centrifugal chiller are

factory wired and mounted to ensure machine protection

against condenser high pressure, cooler low temperature,

bearing or motor overtemperature, motor overload and oil

low pressure. Other safety controls ensure no-load starting

of compressor and prevent compressor restart until a safe,

preset interval has elapsed.

The capacity control system is a fully automatic, modular,

solid state system for precise control of machine capacity

at all loads. When it is desirable to use pneumatic controls

to interface with a complete pneumatic system, control

interface devices or complete pneumatic control systems

are available.

The operating capacity of each chiller is matched directly

with the need for cooling. As cooling needs change, guide

vanes in the refrigerant vapor stream entering the com

pressor change position to maintain the selected chilled

water (brine) temperature.

The changes in vane position are initiated by a solid state

thermistor in the chilled water line. This probe constantly

relays any variations in water temperature to a solid state

capacity control module in the chiller control center. The

control module, in turn, amplifies and modulates the probe

signals. The amplified signals cause a guide vane actuator

motor to adjust the guide vane position as required.

If chilled water temperature drops below the selected

design temperature, the actuator moves the guide vanes

towards a closed position; the rate of refrigerant evap

oration slows and chiller capacity decreases. A rise in

chilled water temperature above the set point causes the

actuator to move the vanes towards a more open position.

Refrigerant begins to evaporate at a more rapid rate and

chiller capacity increases.

Built-in safeguards in the capacity control system

prevent motor overload. When motor full load current is

reached, the guide vanes stop opening immediately If

motor current continues to increase, the guide vanes begin

to close until motor current is reduced. To minimize start

up current demand, capacity control interlocks keep the

guide vanes in a closed (minimum capacity) position until

the compressor motor reaches run condition.

44