Carrier 50DL User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

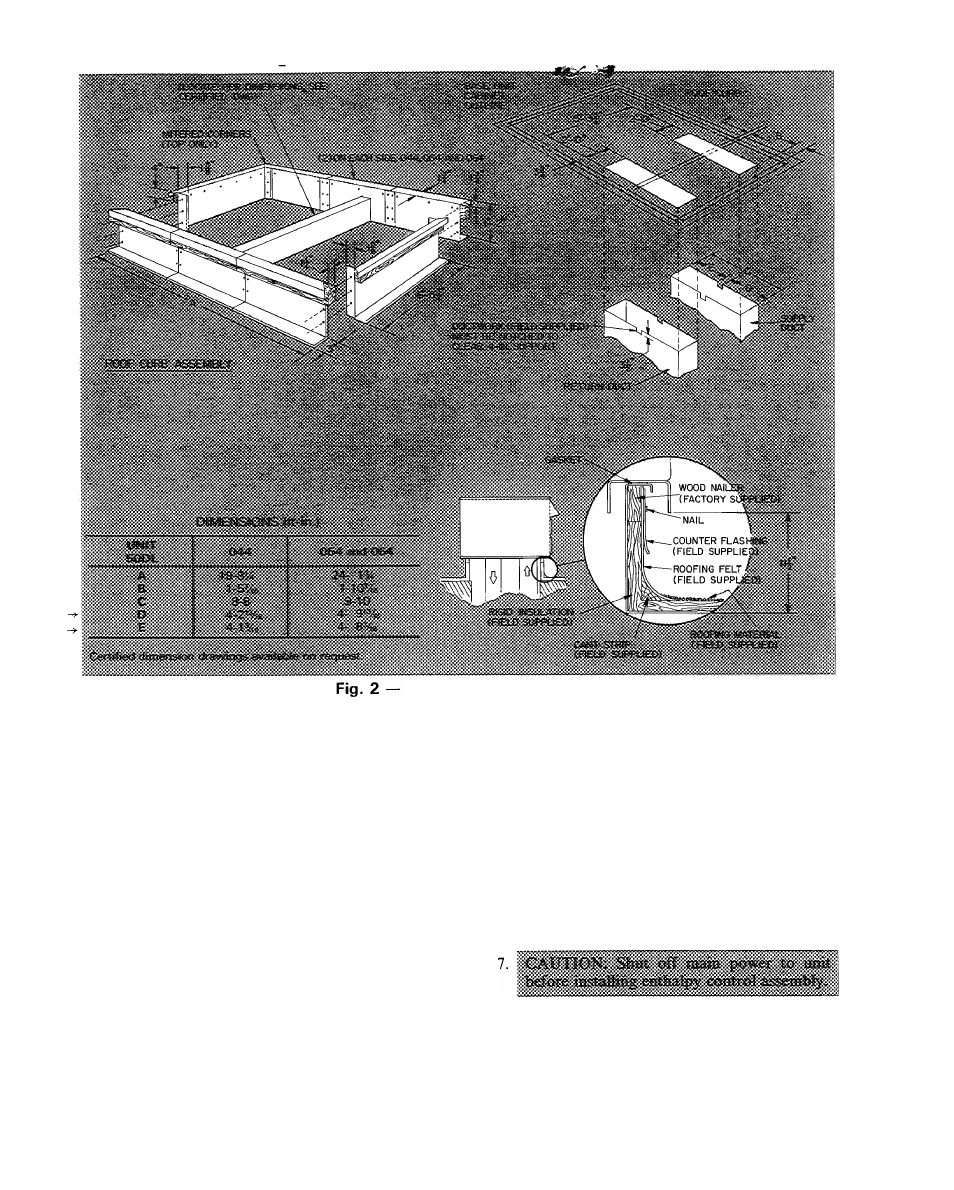

Roof Curb Dimensions

Insulate ducts passing thru unconditioned spaces

and cover with a vapor barrier.

Maintain one-in. minimum clearance between

supply air duct and any combustible material for at

least 3 ft of duct run from unit.

Unit is shipped set up for thru-the-bottom duct

connections. Ductwork openings are shown in

Fig. 4.

Economizer Section

ECONOMIZER HOODS INSTALLATION (Fig.

5) — The economizer mechanism and all electrical

connections are factory installed and adjusted

except as noted below. Hood assembly, outdoor air

inlet screens and required hardware are shipped

separately and must be field installed. Units have 2

hood assemblies.

Install economizer hoods and enthalpy control

as follows:

1. Loosen unit top panel sheet metal screws above

outdoor air inlet opening.

2. Assemble hood top panel, side panels and

support channel.

3. Insert hood flange between unit top panel flange

and unit. Slots are provided in hood flange to

clear sheet metal screws. Tighten sheet metal

screws. Apply RTV sealant to surfaces as shown

in Fig. 5.

4. Secure hood side panels to outdoor air opening

flanges, using screws provided.

5. Install hood support bracket(s) between U-

channel and support channel.

6. Install screen retainer on support channel,

using screws in the slots. Do not tighten.

8. Remove enthalpy control assembly from ship

ping location on horizontal deck in return air

filter compartment.

9. Using 4 no. 10-1/2 screws from envelope in con

trol assembly junction box, mount enthalpy

control assembly to inside of economizer hood

side panel nearest condenser section (Fig. 4).

288