Carrier 50DL User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

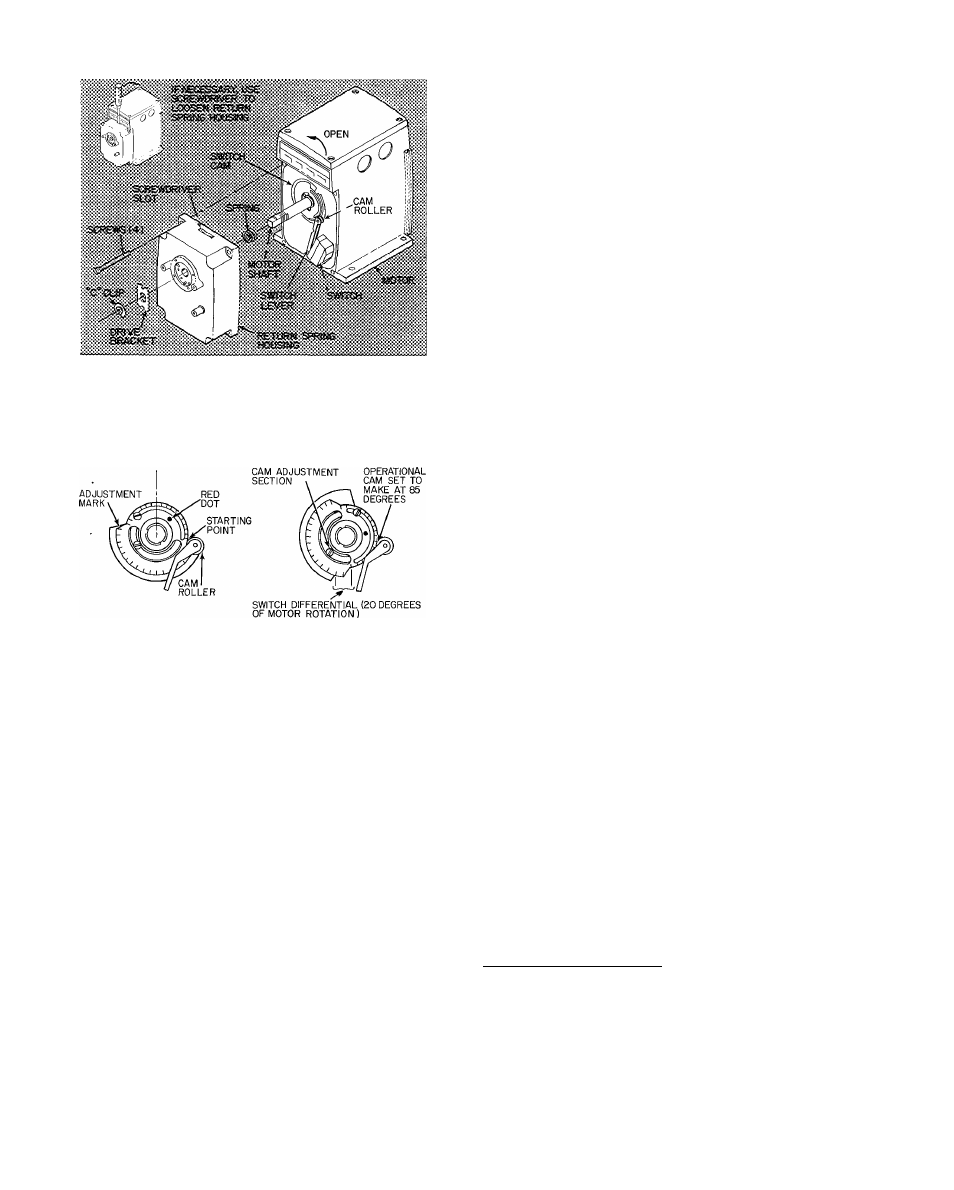

Fig. 18 — Removing Return Spring

Mechanism

STARTING POSITON

NOTE POSITION

OF RED DOT

CENTERLINE

ADJUST CAMS

OPERATIONAL

Each adjustment mark repre

sents 10 degrees of motor rota

tion Use marks and center of

cam roller as adjustment guide

Loosen operational cam adjust

ment screw Rotate both cams

clockwise the number of de

grees motor must travel before

switch makes Tighten screw

Red dot will be to right of centerline if switch is properly adjusted

Fig. 19

Adjusting Switch Make and

Break Points

CAPACITY CONTROL, HEATING — Stages 1

and 2 of heaters are controlled by heating relays

HRl and HR2, respectively. Using a suitable

ammeter, check heater current draw for heating

assemblies or elements. When checking second-

stage heater operation, be sure heating thermostat

is set high enough to activate second-stage heaters.

Also, check operation of outdoor air thermostats if

additional staging is provided.

Modu-Pac® Variable Volume Units

— Units

suitable for use with Modu-Pac variable air volume

systems (i.e. Carrier 37 Series terminal units) are

equipped with electric unloaders on the no. 1 com

pressor and hot gas bypass on the no. 1 refrigerant

system.

Before starting unit, open compressor service

valves and liquid line shutoff valve. Be sure com

pressor crankcase heaters are on and crankcase oil

level is half full. See Compressor and Crankcase

Heaters as applicable.

CONTROL SEQUENCE CHECKOUT

1. Turn on unit main power supply. Be sure unit is

ready to operate. Turn off compressor circuit

breakers.

2. Set the control band knob (Fig. 12) on micro

processor to 8° (50DL044) or 6° (50DL054,064).

3. If unit is not in DAY (OCCUPIED) mode, turn

on unit by overriding time clock with manual

bypass switch on remote box cover.

4. To check for cooling, turn set point knob

(Fig. 14) on microprocessor to 40 F. As cor

responding stage of cooling come on, the LED’s

should glow. Indicator light, located on remote

box cover, should also be lit.

5. Turn set point knob on microprocessor to 90 F.

The LED’s on microprocessor should go out as

corresponding stages turn off (providing ambient

temperature is below 90 F).

6. To check for heating on units with electric heat,

set morning warmup thermostat (Fig. 12),

located in variable volume box, to its maximum

position. If return air temperature is below the

set point, first stage of heat should come on. The

outdoor dampers should be tightly closed. Light

marked HEATING on the cover of remote box

should come on. NOTE: If unit has been in cool

ing mode, it will be necessary to shut off unit

power momentarily in order to check out heating

mode; once unit goes into cooling mode, a hold

ing relay locks out heating mode.

7. The morning warmup thermostat is a 2-stage

device. When first stage is satisfied, control shuts

down electric heat (if used). An adjustable dead

band of 3F to 10 F exists between first and

second stage. In the deadband zone, indoor air

fan runs but cooling mode will not begin until

return air temperature exceeds adjustable set

point of the second stage. Note that the difference

between heating and cooling set points will

always be 3 F to 10 F.

8. When checkout is complete and unit operation is

satisfactory, turn off bypass switch, position the

set point knob on microprocessor to desired

setting (approximately 55 F) and replace all

unit panels.

ECONOMIZER OPERATION — Refer to Con

stant Volume Units, Economizer Operation.

7-DAY TIME CLOCK ADJUSTMENT

Setting ON and OFF Times (Fig. 20) — NOTE:

14 trippers (7 sets, one set for each day) are included.

If more than 7 ON-OFF operations per week are

required, additional trippers are needed.

1. To set ON (OCCUPIED) time, slip the ON

tripper over edge of time dial and position at

desired day of the week and time of the day (AM

or PM). (When switch is turned on, normally

open contacts close and normally closed con

tacts open.)

14