Carrier 50DL User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

m

As the conditioned space temperature approaches

the thermostat’s cooling set point, stages cycle off,

last stage first. After all stages of mechanical

cooling are off, economizer modulates to minimum

position.

During the cooling cycle, a discharge air sensor

senses discharge air temperature. If discharge air

temperature drops below 62 F, the economizer

modulates toward minimum position. At 50 F dis

charge temperature, the economizer will be at mini

mum position.

At the end of the DAY (OCCUPIED) mode on

the clock, unit controls enter the NIGHT (UN

OCCUPIED) mode. Economizer closes. Indoor air

fan runs only on a call for heating or cooling. Tem

perature controls go into HEATING SETBACK,

COOLING SETUP or COOLING SHUTDOWN

mode.

HEATING SETBACK is field selectable at the

unit for 5°, 10°, or 15° below set point on room

thermostat.

COOLING SETUP is field selectable at the unit

for 5°, 8°, or 12° above set point on room

thermostat.

During the UNOCCUPIED mode, unit continues

to use economizer cooling first and then integrates

economizer cooling with mechanical cooling to

meet cooling requirements.

A 5-hour bypass timer is located in the remote

control box to provide air conditioning during

normally unoccupied hours.

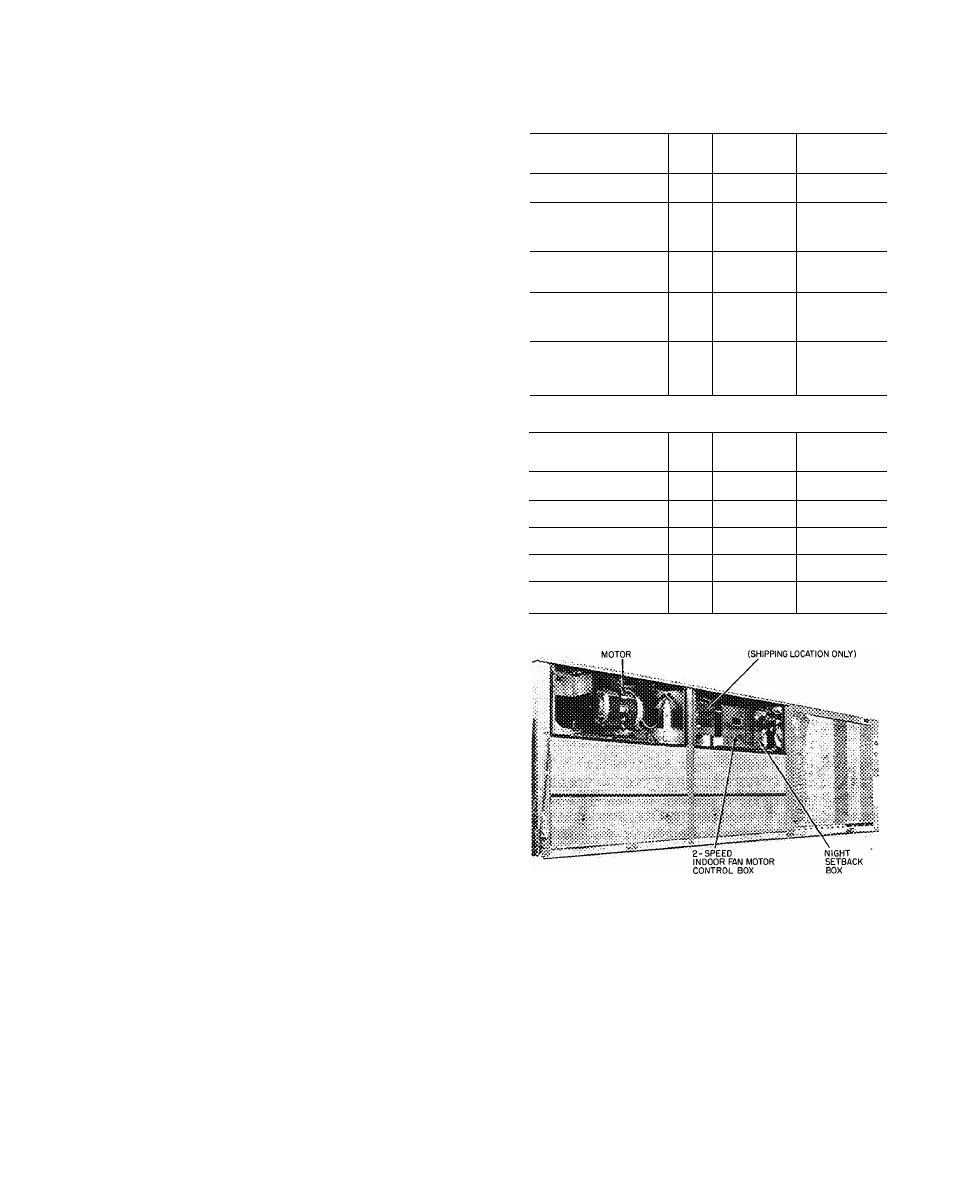

TWO-SPEED INDOOR FAN OPTION — Table 1

lists the 2-speed indoor fan motor hp, frame size and

shaft diameter. Due to the larger frame size, the

208/ 230-volt, 25-hp motors and all 30-hp motors are

available in single speed only.

The 2-speed motors are 2 winding (4 pole/6 pole)

design, with speeds of 1750/1170 rpm. Indoor fans

automatically operate at low speed until high speed

is necessary to maintain comfort conditions. No

field wiring or adjustment is necessary.

COOLING mode sequence of operation is out

lined in Table 4.

In HEATING mode, the indoor fan operates at

low speed for ventilation only, and operates at high

speed during active heating. A 2-heat/4-cool logic

panel provides the necessary fan control.

The circuit breakers, contactors, and relays re

quired for 2-speed motor control are located in the

2-speed indoor fan motor control box (Fig. 17).

POWER EXHAUST OPERATION — Units have

an auxiliary switch located on the damper motor.

This switch is factory set to prevent the power

exhaust fans from operating when the economizer

damper is less than 30% open.

If other than factory setting is desired, adjust

as follows:

Table 4 — Two-Speed Indoor Air Fan

Staging; Cooling Mode

ECONOMIZER COOLING (Enthalpy Permitting)

OPERATING

CONDITION

FAN

SPEED

ECONOMIZER

DAMPER

POSITION

COMPRESSOR

OPERATION

NO CALL FOR COOLING

(Ventilation Air)

Low

Minimum

Position

Off

CALL FOR

MINIMUM COOLING

Low

Modulating

Between

Min and

Full Open

Off

STAGE 1 OF

LOGIC PANEL

(Economizer Cooling)

High

Full Open

Off

STAGE 2 OF

LOGIC PANEL

(Integrated Econ/Mech

Cooling)

High

Full Open

Compr 1

STAGE 3 AND 4

OF LOGIC PANEL

(Integrated Econ/Mech

Cooling)

High

Full Open

Compr 1 and 2

MECHANICAL COOLING

(Enthalpy Not Permitting Economizer Cooling)

OPERATING

CONDITION

FAN

SPEED

ECONOMIZER

DAMPER

POSITION

COMPRESSOR

OPERATION

NO CALL FOR COOLING

(Ventilation Air)

Low

Minimum

Position

Off *

STAGE 1 OF

LOGIC PANEL

Low

Minimum

Position

Off

STAGE 2 OF

LOGIC PANEL

Low

Minimum

Position

Compr 1

STAGE 3 OF

LOGIC PANEL

Low

Minimum

Position

Compr 1 and 2

STAGE 4 OF

LOGIC PANEL

High

Minimum

Position

Compr 1 and 2

INDOOR FAN

REMOTE CONTROL PANEL

Fig. 17 — Two-Speed Fan Control Box

Location

NOTE: Adjustment does not require running the

motor.

1. Motor must be in the fully closed position.

2. Referring to Fig. 18, take off “C” clip and drive

bracket. Remove screws at 4 corners of housing.

Pull off return spring housing.

3. Remove spring on motor shaft.

4. Adjust switch as shown in Fig. 19.

5. After adjustment, replace spring on motor shaft

and reassemble return spring housing.

13