Carrier 50DL User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

reading should gradually increase to about

16 VDC. (See Fig. 23.)

5. Move the cooling lever above room temperature.

Meter reading should drop to less than 2 VDC.

6. Remove the (+) meter lead from terminal 4 and

connect it to terminal 5.

7. Slowly move the heating lever above room tem

perature to simulate a call for heating. Meter

5000

4800

4600

4400

4200

4000

3800

3600

3400

3200

3000

2800

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

N L____

\

^30

OOnAT 77F( >50

'

60

65

70

75

80

85

90

95

100

(16) (18) (21) (24)

(27)

(29)

(32) (35)

(38)

TEMPERATURE DEGREES F (DEGREES C)

Fig. 22 — Resistance Range of

the Discharge Sensor

reading should gradually increase to about

16 VDC. (See Fig. 23.)

8. Move the heating lever below room temperature.

The meter reading should drop to less than

2 VDC.

ECONOMIZER (Motor Operation) — Check to

see 115 V is at the economizer motor. Remove wire

from the W terminal on damper motor. Dampers

should go fully open.

Short between R-W on motorterminals. Dampers

should go fully closed.

Logic Panel Economizer Signal

1. Disconnect terminal W on logic panel.

2. Connect meter (2.5 VDC scale) with negative (-)

lead to R and the positive (+) lead to W.

3. Set thermostat for a call for cooling. Meter

reading should rise to 1.5 VDC. If thermostat

was already calling for cooling, reading will be

1.5 V when meter is connected.

4. Turn thermostat up so that no cooling is called

for. Voltage should fall from 1.5 VDC to 0.

Conduct the above test with air temperature at

the discharge sensor (located at unit air dis

charge) above 62 F. If air is below 50 F, there will

be no voltage signal. If air is between 50 F and

62 F, voltage will be in the same proportions.

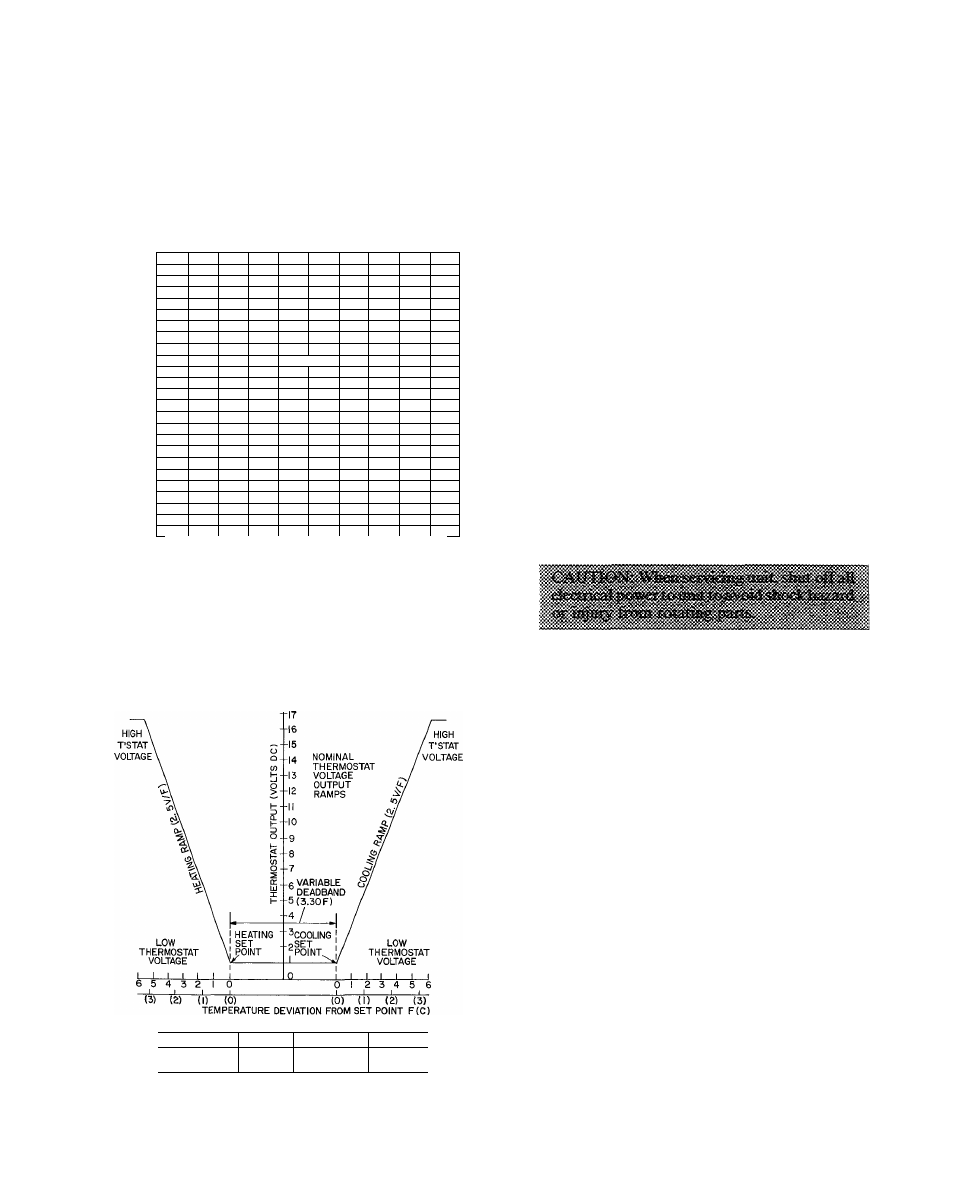

VOLTAGES NECESSARY TO ACTIVATE LOGIC PANEL

HEAT STAGE

VOLT DC

COOL STAGE

VOLT DC

1

4 63

1

5 00

2

5 88

2

5 88

Differential: 63 +

07 volts

Tolerance: i 25 volts

Fig. 23 — Thermostat/Transmitter

Output Voltage Ramps

Cleaning

— Inspect unit interior at the beginning

of each heating and cooling season and during each

season as operating conditions require. Remove unit

top panel(s) and/ or side panels as required to expose

unit interior.

EVAPORATOR COILS — Clean with a stiff

brush, vacuum cleaner or compressed air.

CONDENSER COILS — Clean with a stiff brush

or vacuum cleaner. When cleaning with compressed

air or low-pressure water or steam, guard against

damaging compressor wiring and nearby controls.

Condenser fan motor(s) is drip-proof but not

waterproof.

CONDENSER SECTION DRAIN — Check that

area under coil is clear and drains freely.

CONDENSATE DRAIN — Check and clean

annually at start of cooling season. In winter, keep

drain and trap dry or protect against freeze-up.

FILTERS — Replace filters at start of each heating

and cooling season or as often as necessary during

each season, depending on operating conditions.

Refer to Table 1 for type and size of filter used.

Filter access panels are shown in Fig. 4. Return air

filter tracks will accept 2 layers of 1-in. thick filters

if 2-in. filters are not available. Do not install bag

filters in standard filter tracks. Do not install

17