Initial start-up, Sequence of operation – Carrier WEATHERMASTER III 38HQ User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

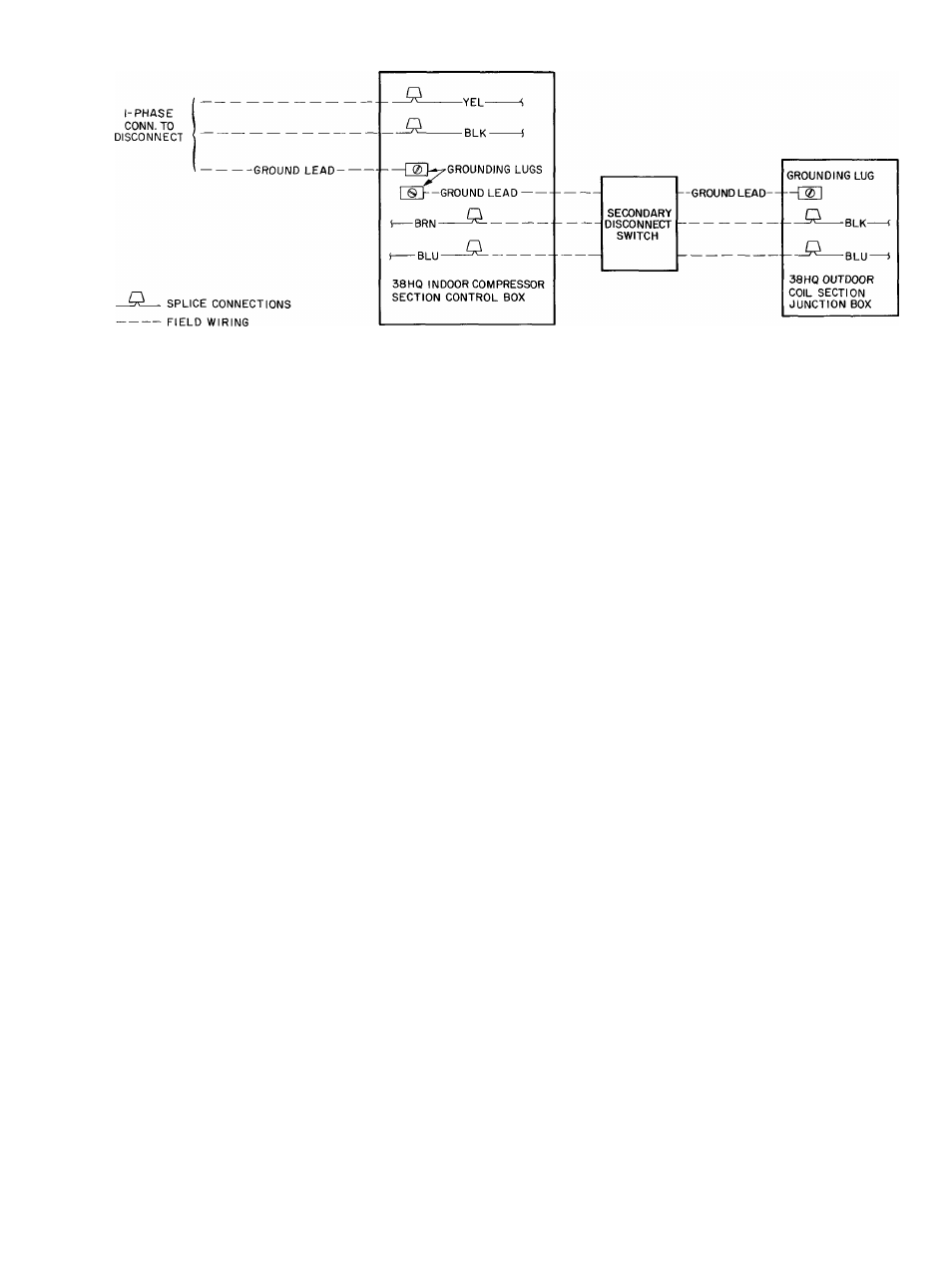

FACTORY WIRING

Fig. 8 — Line Power Connections

INSTALL A BRANCH CIRCUIT DISCONNECT

PER N.E.C. of adequate size to handle compressor

section starting current. Provide a separate dis

connect switch for outdoor coil section. Provide a

separate disconnect for indoor fan-coil and for each

accessory electric heater circuit as required. (See In

door Unit and Electric Heater Installation, Start-Up

and Service Instructions.) Locate disconnect(s)

within sight of and readily accessible to the units, per

section 440-14 of National Electrical Code (NEC).

ROUTE LINE POWER LEADS INTO COM

PRESSOR SECTION — Extend lead from discon

nect per N.E.C. thru 1-1/8 in. hole provided in com

pressor section top panel (Fig. 2) and into control

box. Extend line power leads for outdoor coil

section thru 7/8-in. hole provided in compressor

section top panel and into control box.

CONNECT GROUND LEADS AND POWER

WIRES — Connect ground leads to the ground lug

in control box for safety. Splice compressor section

line power leads to yellow and black pigtails, and

outdoor coil section power leads to brown and blue

pigtails. Use wire nuts and tape at each splice con

nection as shown in Fig. 8.

CONNECT POWER LEADS FROM INDOOR

COMPRESSOR

SECTION

TO

OUTDOOR

COIL SECTION thru secondary disconnect switch.

From this disconnect switch extend leads thru

hole provided in outdoor eoil section basepan

(Fig. 1) and into line voltage seetion of junction

box. Fig. 14. Splice leads to black and blue pigtails

with wire nuts.

CONNECT CONTROL WIRING (24-v) — Extend

wiring thru 7 / 8-in. grommeted hole in compressor

section top panel (Fig. 2), and to control wiring

terminal board on side of control box. Connect

leads to terminal board as shown in Fig. 7. Extend

and connect control wiring from compressor section

to outdoor coil section as required. Make splice

connections in low-voltage section of coil junction

box.

Use indoor fan-eoil transformer as 24-v supply for

system. Be sure fan eontrol package is installed as

described in Step 6. Package contains 75-va trans

former of adequate capacity to handle system

current.

INITIAL START-UP

The compressors in the indoor compressor

section are equipped with crankcase heaters. It is

reeommended that the heaters be energized a

minimum of 24 hours before starting the system. To

energize crankcase heaters only, set the thermostat

at OFF position and turn on main power to

compressor section.

To Start System

— (Be sure crankcase heaters

have been energized for 24 hours.) Adjust the ther

mostat as follows;

1. Set selector switch at OFF.

2. Turn on main disconnect switch(es) to indoor

and outdoor units.

3. Set fan switch as desired (ON or AUTO.).

4. Set thermostat dial at desired temperature.

5. Set selector switch at HEAT or COOL.

Check system refrigerant charge. See Service —

Refrigerant Charging.

SEQUENCE OF OPERATION

Fan Switch at AUTO. Position, Thermostat at

ON Position

(Crankcase heater is on as soon as the

field power supply is on.)

THERMOSTAT CALLS FOR COOLING

1. First-stage cooling thermostat (Co) closes and

the reversing valve solenoid (RVS) is energized.

The RVS actuates the reversing valve and

switches the system to cooling.

2. Second-stage cooling thermostat (Cl) closes. If

the low-pressure switch (LPS) is closed, com

pressor contactor (C) is energized and compres