Carrier WEATHERMASTER III 38HQ User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Attach one lead to compressor terminal board

connection OA. Connect other lead to line side of

defrost thermostat.

Set switch at temperature of first thermal balance

point (heating). This balance point is provided by

CLIC load estimating program. Further adjust

ments can be made following operating experience.

Step 8 — Install Room Thermostat, Outdoor

Thermostat(s) and Emergency Heat Relay —

Follow Installation Instructions shipped with these

accessories plus the instructions in the sections that

follow. Connect as described in step 9.

INDOOR THERMOSTAT — Use only Carrier

indoor thermostat and subbase as shown in Table 4.

Set heat anticipator settings according to Table 5.

These settings may be changed slightly to provide

a greater degree of comfort for certain installations.

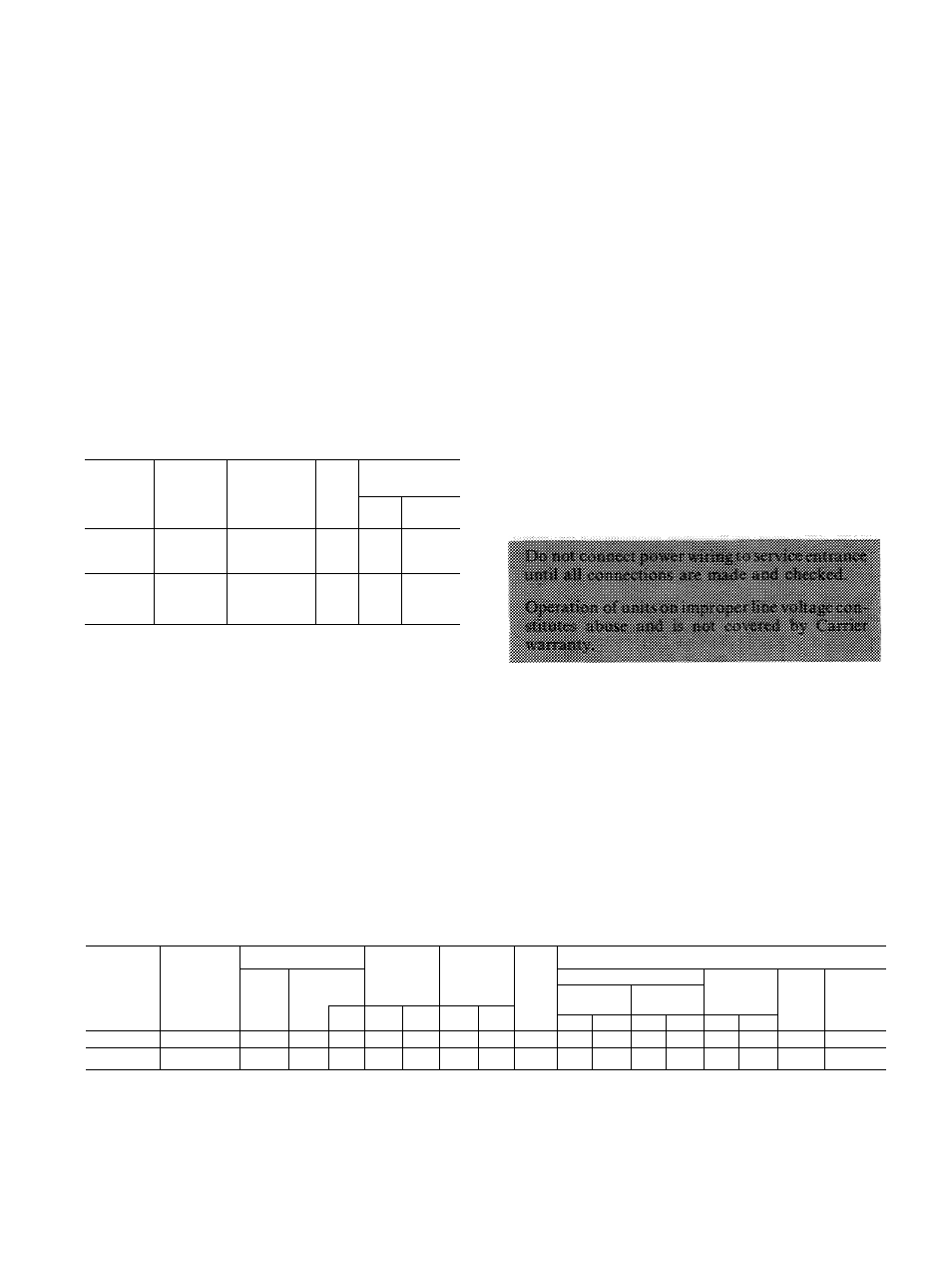

Table 5 — Thermostat Heat Anticipator

Settings

INDOOR

COMPR

SECTION

OUTDOOR

COIL

SECTION

INDOOR

UNIT WITH

ELECTRIC

HTR

HTR

KW

ANTICIPATOR

SETTINGS

First

Stage

Second

Stage

38HQ227

38HQ940

40FS160 with

40FQ916010

thru 090

8 thru

20

Fixed

16

38HQ234

38HQ960

40FS200 with

40FQ920060

thru 150

10 thru

25

Fixed

49

OUTDOOR THERMOSTAT ACCESSORY pro

vides adjustable outdoor control of accessory

electric heater (used on indoor fan-coil). This ther

mostat closes on a drop in outdoor temperature.

It energizes a stage of electric heat when the out

door temperature setting is reached, provided the

room thermostat is on the second stage of heating.

One outdoor thermostat is recommended for each

stage of electric heat after the first stage. Connect

as described in Step 9. Set the outdoor thermostats

progressively lower for each stage. Refer to heat

load of building and unit capacity to determine the

correct outdoor thermostat settings. Locate maxi

mum of 2 outdoor thermostats in control voltage

section of outdoor coil section junction box. Fasten

in place with sheet metal screws.

EMERGENCY HEAT RELAY — This accessory is

required when 2 or more outdoor thermostats are

used. It is automatically energized by the manually-

operated emergency heat switch in the indoor ther

mostat subbase. The indoor thermostat locks out

the compressor and the relay bypasses the outdoor

thermostats for electric heater operation during heat

pump shutdown. When one outdoor thermostat is

used, an emergency heat relay is not required. The

emergency heat switch in the indoor thermostat

subbase bypasses the outdoor thermostat, locks out

the compressor and activates the electric heater.

Install emergency heat relay in a convenient loca

tion on indoor unit. Attach with sheet metal screw.

Connect relay as shown in Fig. 7.

Step 9 — Make Electrical Connections

— In

stall field wiring in accordance with local and

national fire, safety and electrical codes. Be sure

voltage to units is within ± 10% of voltage indi

cated on nameplate. Contact local power company

for correction of improper line voltage.

When making electrical connections, provide

clearance at unit for refrigerant piping connections.

See Table 6 for recommended wire and fuse sizes.

Line power connections and control circuit connec

tions are shown in Fig. 7 and 8.

Route line and control power wiring for 38HQ

outdoor coil from connections in the 38HQ in

door compressor section. Use 14-ga (minimum) line

power wire size to outdoor coil section when total

wire length connecting compressor section to coil is

under 25 feet. If over 25 ft, use same wire size as

compressor section branch circuit.

Table 6 — Electrical Data

INDOOR

COMPR

SECTION

OUTDOOR

COIL

SECTION

VOLTAGE

COMPR

1

COMPR

2

OFM

(FLA)

BRANCH CIRCUIT

Nom

1-Ph

60-Hz

Operating*

Power Wire

Gnd Wire

Sizet

(AWG)

Min

Ckt

Amps

Max

Fuse

Amps“

Min Size

(AWG)

Max Ft

Max

Min

LRA

RLA

LRA

RLA

ICS

OCS

ICS

OCS

ICS

OCS

38HQ227

38HQ940

230

254

207

72

17

88

17 8

1 5

6

14t

55

25t

10

14t

40 8

50

38HQ234

38HQ960

230

254

207

88

20

94

21 2

2 3

4

14t

75

25t

10

14t

48 8

60

FLA — Full Load Amps

ICS — Indoor Compressor Section

LRA — Locked Rotor Amps

OCS — Outdoor Coil Section

OFM — Outdoor Fan Motor

RLA — Rated Load Amps

‘Permissible limits of the voltage range (for limited period of time)

at which the units will operate satisfactorily

fOutdoor coil section wiring — for 25 ft wire run or less, use

minimum 14 AWG size wire For longer wire run use same size

as supply to compressor section

^Required when using nonmetallic conduit

“Maximum dual element fuse size

NOTES;

1 All units have 24-v control circuit which requires external

power source

2 Copper wire size table based on 60 C Use copper or copper-clad

aluminum wire to indoor section; copper wire only to outdoor

section Use latest National Electrical Code for wire sizing