Pumpdown procedure (cooling cycle) — the – Carrier WEATHERMASTER III 38HQ User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

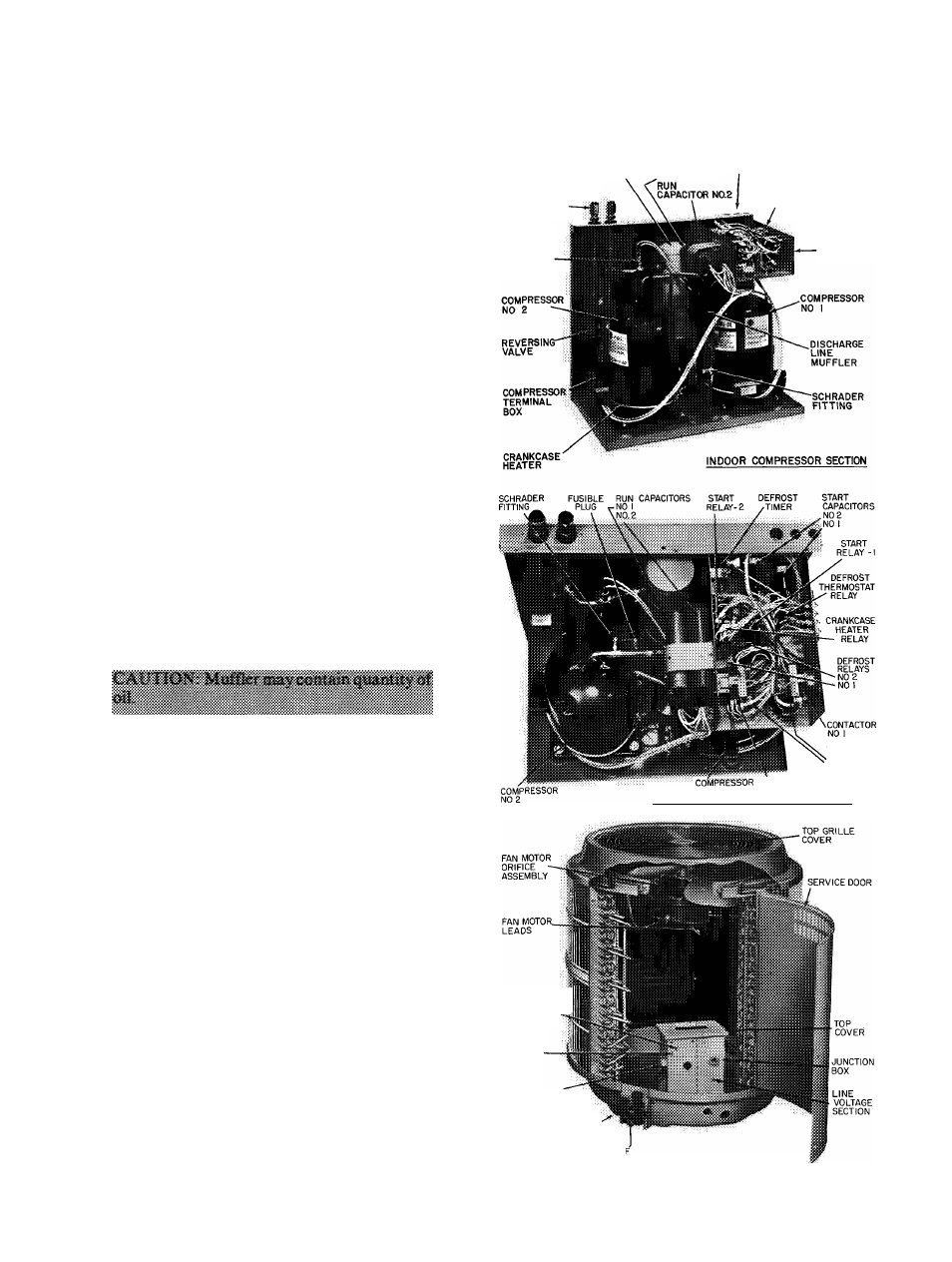

Compressor Removal

— See Table 2 for com

pressor information; Fig. 14 for component loca

tion. Shut off power to unit. Remove refrigerant

from system using refrigerant removal methods

described in Carrier Standard Service Techniques

Manual, Chapter 1, Refrigerants.

Follow safety codes, and wear safety glasses and

work gloves. Have quenching cloth available.

If either compressor fails due to motor burnout,

it is necessary to replace both compressors. Since

both compressors use common oil, one compressor

burnout contaminates both compressors.

1. Remove unit top cover and front access

wrapper.

2. Remove compressor terminal box cover, dis

connect and remove compressor power leads.

3. Using a tubing cutter, cut suction and discharge

lines at convenient place near compressor for

easy reassembly to new compressor with copper

slip couplings.

4. Disconnect equalizer tube from compressor

shell.

5. Remove crankcase heater from compressor

base.

6. Remove compressor hold-down bolts. Lift out

compressor.

7. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

8. Braze piping stubs (removed in step 1) onto new

compressor.

9. Clean system. Add new liquid line heat pump

filter-drier as described below.

10. Install new compressor in unit. Braze suction

and discharge lines to compressor piping stubs

(at points where cut, step 3) using field-supplied

copper couplings. Reconnect equalizer tube.

Teflon O-ring in fitting is reusable. Torque

fitting to 30-40 ft-lb. Ensure compressor hold

down bolts are in place. Connect wiring.

11. Evacuate and recharge system.

Lubrication

— Compressor contains factory oil

charge. Replace oil when lost. See Table 2 for oil

recharge. If necessary, refer to Carrier Standard

Service Techniques Manual, Chapter 1, Refrig

erants, pages 1-21, for oil recharging procedure.

Use Carrier PP33-1, Texaco Capella B or Suniso

3G oil.

Filter-Drier

— Install accessory heat pump filter-

drier (Table 4) in system liquid line when refrig

erant system is opened for service as described under

Compressor Removal. Position drier in liquid line at

convenient location.

Pumpdown Procedure (Cooling Cycle)

— The

38HQ units may be pumped down in order to make

repairs on low side of system without losing com

plete refrigerant charge.

SUCTION LINE

ACCUMULATOR

RUN, CAPACITOR

VAPOR LINE

CONNECTIONS

LOW

PRESSURE

SWITCH

CONTROL WIRE

TERMINAL BOARD

.CONTROL

BOX

SIGNAL-LOG"’

N01

N0 2

'CONTACTOR

N0.1

N0.2

INDOOR COMPRESSOR SECTION-TOP VIEW

ACCESSORY

OUTDOOR

THERMOSTAT

LOCATION

CONTROL

VOLTAGE

SECTION

DEFROST

THERMOSTAT'

LIQUID LINE SERVICE'

VALVE(WITH SERVICE PORT)

VAPOR LINE SERVICE VALVI

(WITH SERVICE PORT)

38HQ OUTDOOR COIL SECTION

Fig. 14 — Component Location

14