Carrier WEATHERMASTER III 38HQ User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Compatible Fitting coupler is used for liquid line

connection. See accessory coupler, Fig. 6.

Connect vapor line from outdoor coil section to

indoor compressor section, and from compressor

section to indoor fan-coil. Section vapor line as

required (Fig. 5). Use correct compressor section

vapor line connection to indoor and outdoor coils.

Unit Compatible Fittings permit mechanical or

sweat connection as described below.

When a 1-1/8 in. field-supplied vapor line is used

on 38HQ234, four field-supplied 3/4-in. to 1-1 / 8 in.

vapor line adapters must be provided.

fitting on unit liquid line connection. Connect liquid

line to Compatible Fitting using mechanical or

sweat connection. When mechanical connection is

made, use 2 wrenches to tighten Compatible Fitting

nut — one to hold coupler and one to tighten nut.

Insulate Refrigerant Lines — After making tubing

connections, the compressor section fittings must be

insulated. Butt the Armaflex tubing insulation (pro

vided in tubing package) against the Compatible

Fittings. Secure the insulation with Prestito or an

equivalent material which provides both adhesion

and insulation. Also wrap the Compatible Fittings

with Prestito to prevent sweating.

Mechanical

Connection-to-Compatible

Fitting

(Mate one set of connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure 0-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length.

4. Insert tube into Compatible Fitting until it

bottoms.

5. Tighten nut until it bottoms on back coupler

flange. Keep tube bottomed in Compatible

Fitting while tightening nut.

Sweat

Connection-to-Compatible

Fitting

(Use

refrigerant grade tubing.)

1. Remove locking nut, rubber O-ring and Schrader

core from valve.

2. Cut tubing to correct length.

3. Insert tube into Compatible Fitting. Wrap top

and bottom of service valves in wet cloth to pre

vent damage by heat. Solder with low tempera

ture (430 F) silver alloy solder.

4. Replace Schrader core.

5. Evaeuate or purge system with field-supplied

refrigerant.

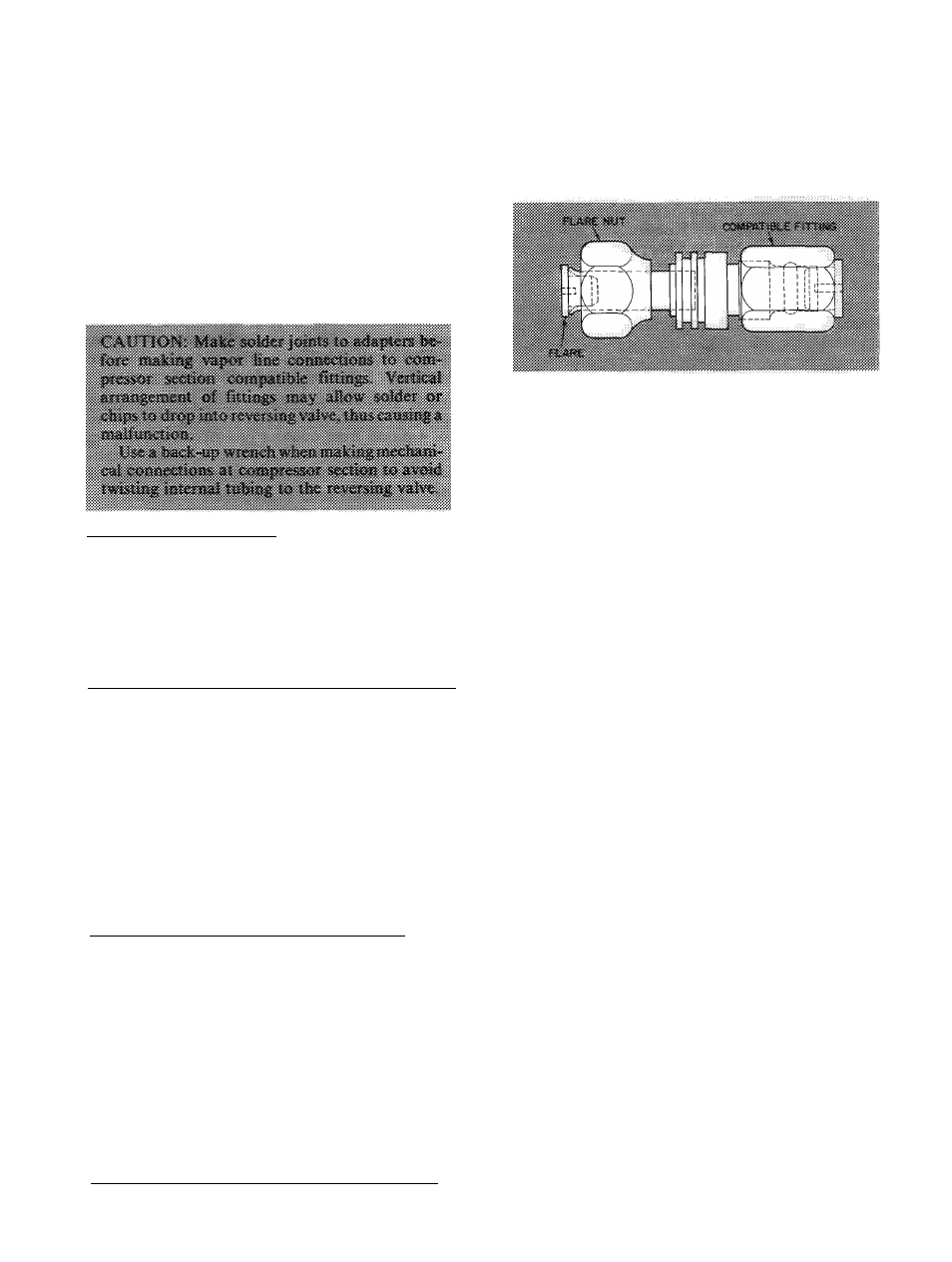

Accessory Flare-to-Compatible Fitting Coupler is

shown in Fig. 6. Attach flare nut on coupler to flare

Fig. 6 — Accessory Coupler

Step 6 — Install Fan Control Package

(factory

supplied; packaged separately inside indoor com

pressor section) — This control, consisting of a

transformer and a relay, provides high-speed fan

operation when both compressors are energized.

Refer to connection diagram in Fig. 7 for wiring

details. Install control as follows:

1.

Remove factory-installed transformer from

indoor fan-coil unit electric heater package.

Refer to 40FS service instructions as required.

2. Install fan control package in upper right-hand

corner of the 40FS.

3. Route wires from controls to heater package thru

knockouts provided. Restore transformer wiring

connections including ground wire.

4. Connect black wire from indoor fan relay (IFR)

terminal no. 4 (or no. 6) to black wire from

indoor fan relay no. 2 (IFR-2) terminal no. 3.

(Cut off male connector from IFR wire; supply

wire nut to splice wires.)

5. Connect black wire from IFR-2 terminal no. 6 to

fan speed selector block terminal no. 1 (high

speed).

6. Connect blue wire from IFR-2 terminal no. 1 to

fan speed selector block terminal no. 3 (low

speed).

7. Connect low-voltage field control wires between

indoor compressor section and indoor fan relay

(IFR-2) orange pigtails (TB OA to OFR-2, ter

minal no. 4; contactor C-2, terminal C to IFR-2,

terminal no. 5). Field-supplied, 24-gage, NEC

Class 2 thermostat wire may be used.

Step

7

—

Install

Outdoor

Ambient

Switch

(OA)

(factory-supplied; packaged separately inside

indoor compressor section) — This switch activates

compressor no. 2 when the first heating thermal

balance point is reached. The switch is installed in

the same manner as the outdoor thermostat (step 8),

except refer to Fig. 7 for correct wiring.