A warning – Carrier WEATHERMAKER 8000 58WAV User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

remains on until the end of the purge period, then shuts off

until the end of the ignition warm up and trial for ignition

periods (a total of 24 sec). The blower then comes back on at

heating speed.

When the W input signal disappears, the control begins the

normal inducer post-purge period and the blower changes to

cooling speed after a 1-sec delay. If the W-Y-G signals should

disappear at the same time, the blower remains on for the

selected heating blower off delay period, and the inducer goes

through its normal post-purge period. If the W-Y inputs

should disappear, leaving the G signal input, the control goes

into continuous blower mode and the inducer remains on for

the normal post-purge period.

While in heat pump mode, the control uses only the 17-sec

ignition warm-up period and does not use the 45-sec period at

all. Any time the control senses false flame, the control locks

out of heating mode. This occurs because the control cannot

sense the W input due to the false flame signal, and as a result,

sees only the Y input and goes into cooling mode blower off

delay. All other control functions remain in standard format.

EAC terminals are energized during blower operation.

HUM-1 is energized only during gas heat or defrost operation.

START-UP PROCEDURES

1. Self-test—The furnace features a self-test system to help

diagnose a system problem in the case of a component failure.

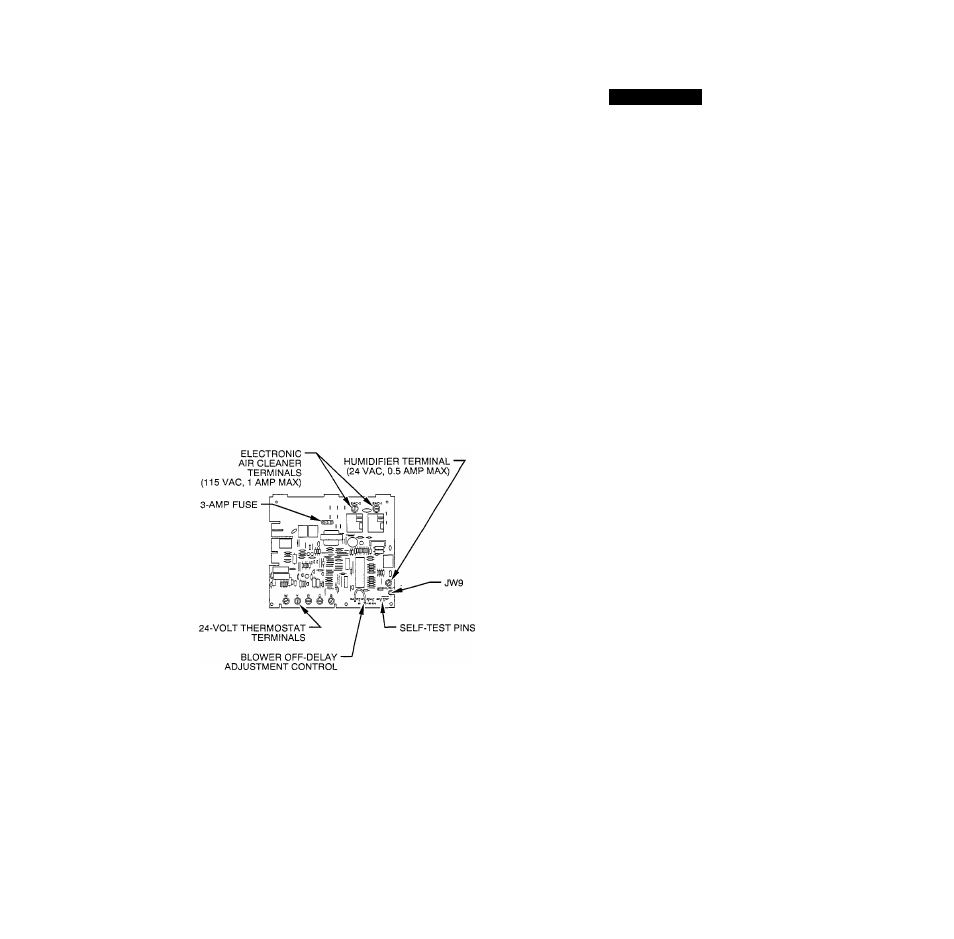

Two test pins (ST-1 and ST-2) are located in the lower

right-hand corner of the control board as shown in Fig. 9. To

initiate the self-test procedure, momentarily short across the 2

pins for approximately 0.5 sec.

A91060

Fig. 9—Control Center

NOTE:

The self-test feature does not operate if the control board

is receiving any thermostat signals.

The self-test sequence is as follows:

a. The furnace control checks itself, then operates the inducer

motor for 10 sec, then stops.

b. The hot surface ignitor is then energized for 15 sec, then

de-energized.

c. The humidifier relay is then energized for 10 sec, then

de-energized.

d. The blower motor operates on cooling speed for 10 sec,

then stops.

e. The blower motor operates on heating speed for 10 sec,

then stops.

2. Purge gas lines—After all connections have been made, purge

the lines and check for leaks.

A

WARNING

Never purge a line into a combustion chamber. Never use

matches, candles, flame or other sources of ignition for the

purpose of checking leakage. Use a soap-and-water solution

to check for leakage. A failure to follow this warning can

cause a fire, explosion, personal injury, or death.

3. To operate furnace, follow procedures on operating instruc

tions label attached to furnace.

4. With furnace operating, set thermostat below room tempera

ture and observe that furnace goes off. Set thermostat above

room temperature and observe that furnace restarts.

ADJUSTMENTS

1. Set gas input rate.

There are 2 methods of adjusting the gas input rate. The

preferred method is by using Table 6 and following instruc

tions in item a. The second method is by clocking the gas

meter and following instructions in item b.

The gas valve regulator has been nominally set at 3.5-in. wc

for natural gas. When adjusting input rate, do not set manifold

pressure above 3.8- in. wc or below 3.2-in. wc.

a. Check gas input rate using Table 6.

(1.) Obtain average yearly heat value for local gas supply.

(2.) Obtain average yearly specific gravity for local gas

supply.

(3.) Verify furnace model. Table 6 can only be used for

model 58WAV Furnaces.

(4.) Check and verify orifice size in furnace. NEVER

ASSUME THE ORIFICE SIZE. ALWAYS CHECK

AND VERIFY.

(5.) Find natural gas heat value and specific gravity in

Table 6.

(6.) Follow heat value and specific gravity lines to point of

intersection. Find orifice size and manifold pressure

settings for proper operation at given natural gas

conditions.

EXAMPLE:

Heat value = 1070 Btu/cu ft

Specific gravity = 0.58

Therefore Orifice No. 44 *

Manifold pressure 3.3-in. wc

* The furnace is shipped with No. 43 orifices. Therefore, in

this example, all main burner orifices must be changed and

manifold pressure must be adjusted.

(7.) Proceed to item c. to adjust manifold pressure,

b. Check gas input rate by clocking gas meter.

(1.) Obtain average yearly heat value for local gas supply.

(2.) Check and verify orifice size in furnace. NEVER

ASSUME THE ORIFICE SIZE. ALWAYS CHECK

AND VERIFY.