For example, A warning – Carrier WEATHERMAKER 8000 58WAV User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SUPPLY

AIR

For Example:

VENT THROUGH ROOF

(OATEGORY I) OR WALL

(CATEGORY III)

! I I

I I I

I

I I

_12 MAX

1 1 SO IN.

Ш

PER 1000

BTUH*

INTERIOR

HEATED

SPACE

6 IN. MIN

(FRONT) +

1 SO IN.

PER 1000

BTUH*

* Minimum opening size is 100 square in. with

minimum dimensions of 3 in.

+ Minimum of 3 in. when type-B vent is used.

A89012

Fig. 2—Air For Combustion and Ventilation

(Inside Air)

For Example:

58WAV FURNACE

INPUT BTUH

FREE AREA PER OPENING

(SQ IN.)

44,000

100

66,000

100

88,000

100

110,000

110

132,000

132

154,000

154

If the building is constructed unusually tight, a permanent opening

directly communicating with the outdoors should be provided.

This opening shall have a minimum free area of 1 sq in. per 5000

Btuh of total input rating for all equipment in the enclosure.

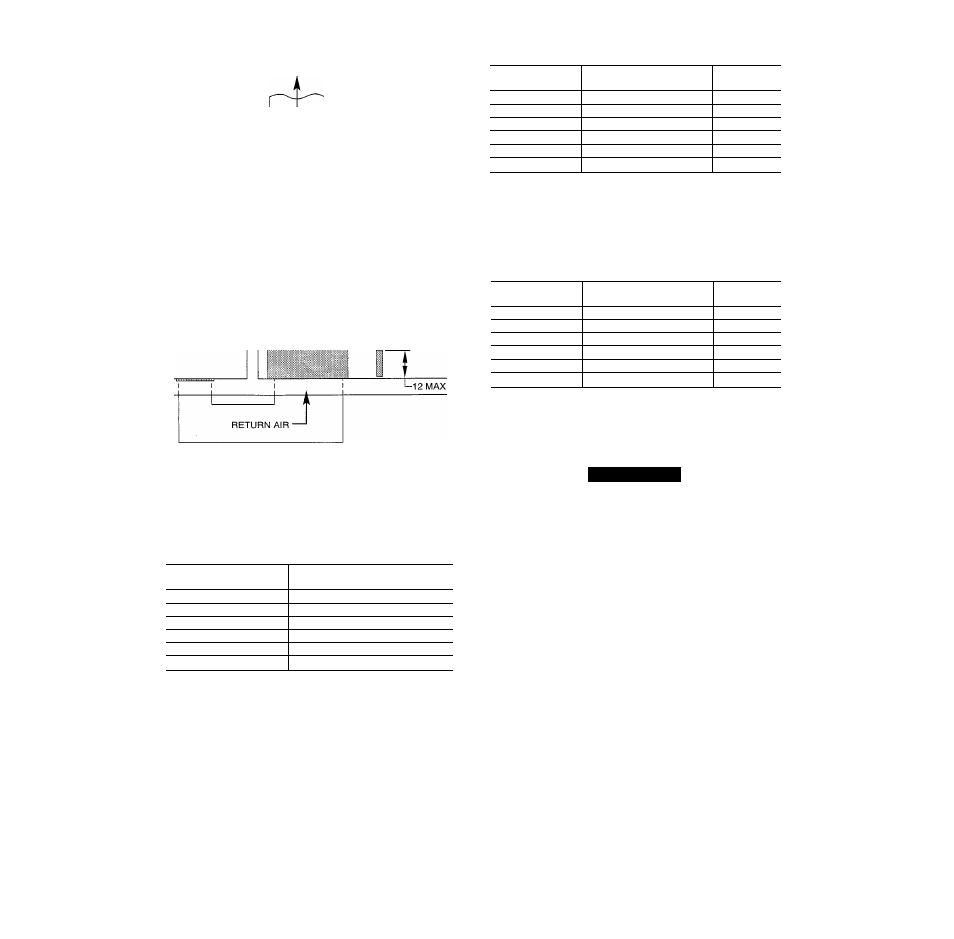

If the furnace is installed on a raised platform to provide a

return-air plenum, and return air is taken directly from the hallway

or space adjacent to the furnace, all air for combustion must come

from outdoors.

2. AJil air from outside the structure:

a. If combustion air is taken from outdoors through vertical

ducts, the openings and ducts MUST have at least 1 sq in.

of free area per 4000 Btuh of the total input for all

equipment within the confined space. (See Fig. 3.)

58WAV FURNACE

INPUT BTUH

FREE AREA PER OPENING

(SQ IN.)

ROUND PIPE

(IN. DIA)

44,000

11.0

4

66,000

16.5

5

88,000

22.0

6

110,000

27.5

6

132,000

33.0

7

154,000

38.5

7

b. If combustion air is taken from the outdoors through

horizontal ducts, the openings and ducts MUST have at

least 1 sq in. of free area per 2000 Btuh of the total input

for all equipment within the confined space.

For Example:

58WAV FURNACE

INPUT BTUH

FREE AREA PER OPENING

(SQ IN.)

ROUND PIPE

(IN. DIA)

44,000

22.0

6

66,000

33.0

7

88,000

44.0

8

110,000

55.0

9

132,000

66.0

10

154,000

77.0

10

When ducts are used, they must be of the same cross-sectional area

as the free area of the openings to which they connect. The

minimum dimension of rectangular ducts must not be less than 3

in. (See Fig. 3.)

A WARNING

Do not install the furnace on its back; safety control operation

will be adversely affected. Never connect return-air ducts to

the back of the furnace. A failure to follow this warning can

cause a fire, personal injury, or death.

Step 3—Filter Arrangement

The factory-supplied filter(s) is shipped in the blower compart

ment. Determine location for the filter and move filter retaining

hardware, if necessary, before attaching the return-air duct. After

the return-air duct has been connected to the furnace, install the

filter(s) inside the furnace blower compartment. See Fig. 4 for side

return application and Fig. 5 for bottom return application.

A bottom closure panel is factory installed in the bottom of the

furnace. When bottom return inlet is desired, remove and discard

the enclosure panel.

Filter retaining brackets, supports, and retainers are factory as

sembled and shipped installed for side return application, with 1

set of all required hardware on each of the furnace. (See Fig. 4.)

For bottom return applications, remove the brackets (front and

back) and supports from each side. The back bracket(s) are

installed in the rear of the furnace casing (dimples are provided to

mark mounting screw locations).

The front bracket(s) are installed on the bottom front plate as

shown in Fig. 5, once the bottom enclosure has been removed.

Rotate filter supports 180° so filter will rest on support, and

reinstall. (Do not reinstall in 17-1/2 in. casing.) Install the filter

retaining rod (small U-shaped end) in the rear bracket, and the

front of the filter retainer rod as shown in Fig. 5. Two sets of

hardware are needed for furnaces in 24-1/2 in. casings using 2

filters for bottom return. All hardware is provided for filter

installation.