Replacing the diaphragm – VACUUBRAND PC 3012 VARIO User Manual

Page 66

Documents are only to be used and distributed completely and unchanged. It is strictly the users’ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999164 / 19/05/2009

Replacing the diaphragm

☞

Check diaphragm for damage and replace if necessary.

➨

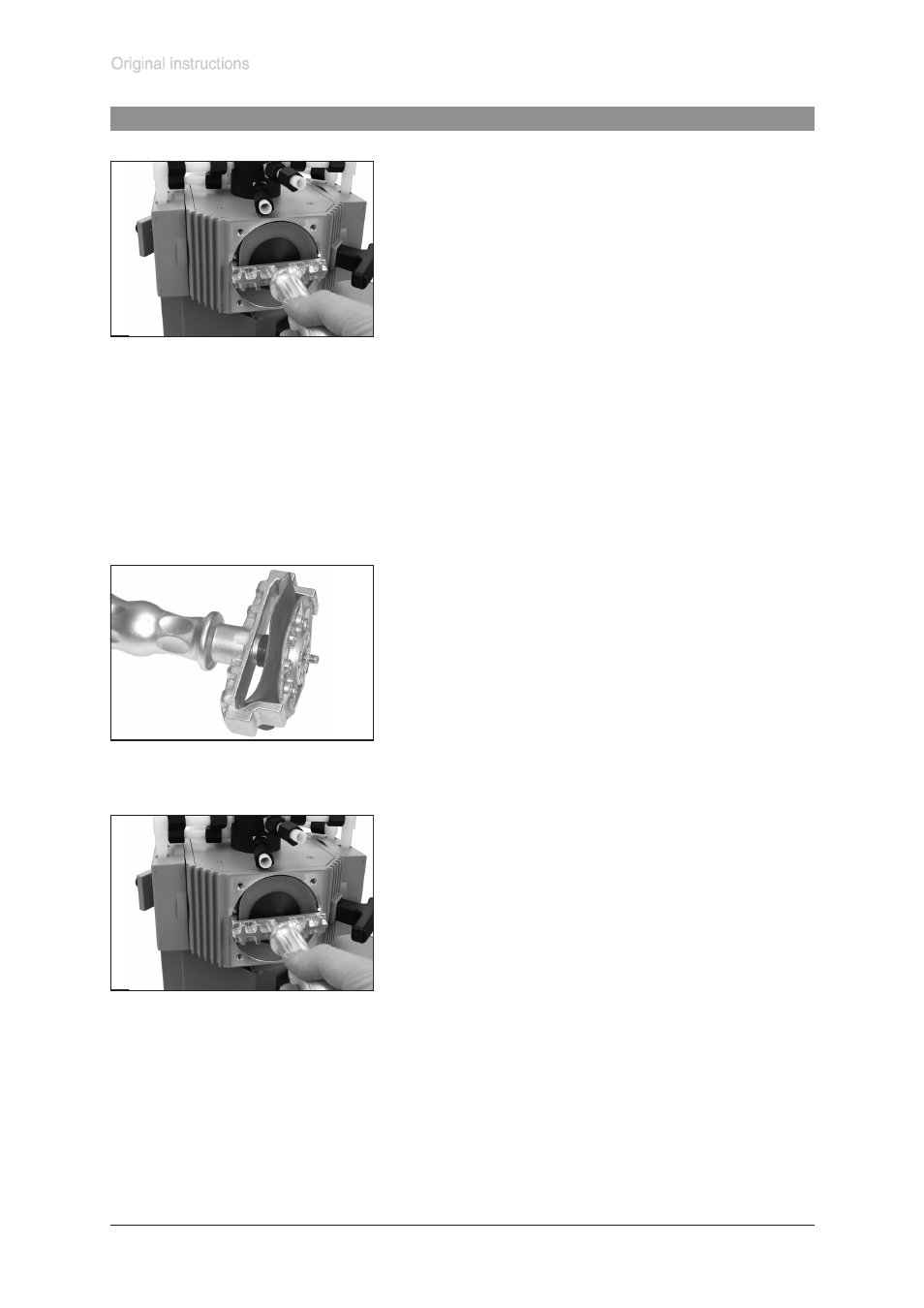

Lift diaphragm carefully sidewise.

☞

Never use a spiky or sharp-edged tool to lift the dia-

phragm.

➨

Use the diaphragm key to grip the diaphragm support disc

below the diaphragm.

➨

Unscrew diaphragm support disc with diaphragm and dia-

phragm clamping disc.

➨

Check for washers between the diaphragm support disc

and the connecting rod. Do not mix the washers from the

different pump heads. Make sure that the original number

is reassembled at the individual pump head.

☞

If the old diaphragm is difficult to separate from the support

disc, immerse assembly in naphtha or petroleum ether. Do

not inhale!

☞

Too small number of washers: The pump will not attain

ultimate vacuum. Too many washers: Clamping disc will

hit head cover; noise or even blockade of the pump.

➨

Position new diaphragm between diaphragm clamping

disc with square head screw and diaphragm support disc.

☞

Attention: Position diaphragm with pale side towards dia-

phragm clamping disc (to pump chamber).

☞

Make sure that the square head screw of the diaphragm

clamping disc is correctly seated in the guide hole of the

diaphragm support disc.

➨

Lift diaphragm at the side and position carefully together

with diaphragm clamping disc and diaphragm support disc

in the diaphragm key.

☞

Avoid damage of the diaphragm: Do not bend diaphragm

too much.

➨

Assemble the original number of washers between sup-

port disc and connecting rod.

➨

Screw diaphragm clamping disc, diaphragm, diaphragm

support disc and washers to connecting rod.

☞

Optimum torque for the diaphragm support disc: 6 Nm, it

is recommended to use a torque key. Attach hex key to

diaphragm key (hexagonal bolt 6 mm wide).

Attention: Never use the diaphragm key with any addi-

tional tools like tongs or hex keys without torque limita-

tion.