Notice – VACUUBRAND PC 3012 VARIO User Manual

Page 22

Documents are only to be used and distributed completely and unchanged. It is strictly the users’ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999164 / 19/05/2009

NOTICE

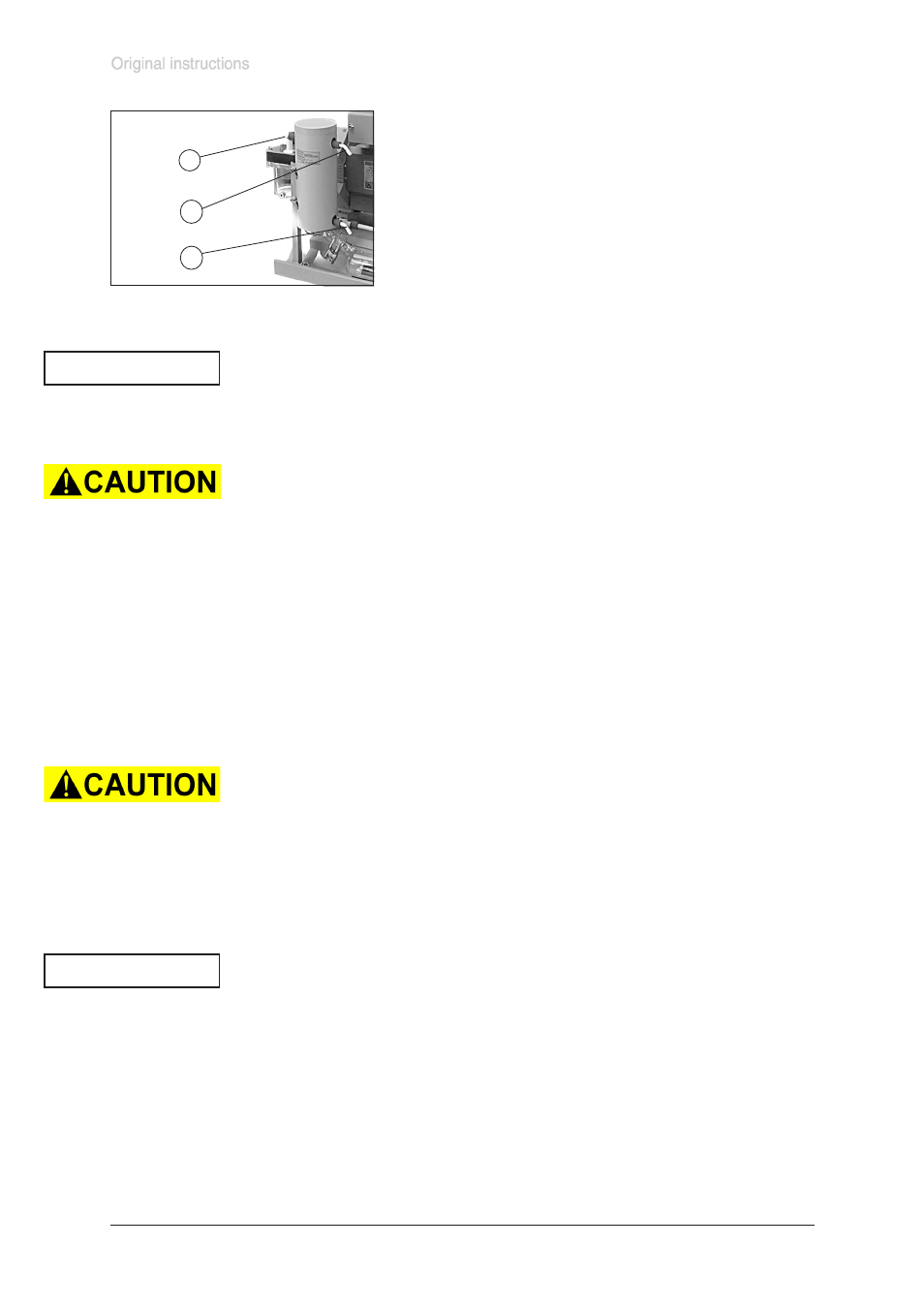

Attach the pipelines of the coolant circuit to the respective hose nozzles (see image,

hose nozzles 6-8 mm) at the waste vapour condenser. Check hose connections prior

to starting operation of the cooling system.

Secure coolant hoses at the hose nozzles (e.g. with hose clip) to prevent their ac-

cidental slipping.

• The gas outlet (hose nozzle 10 mm) must not be blocked. The exhaust pipeline has

always to be free and pressureless to enable an unhindered discharge of gases.

• Connect the exhaust to a suitable treatment plant to prevent the discharge of

dangerous gases and vapours to the surrounding atmosphere.

•

Attention: Install hoses of the cooling system in a way to avoid flow / dropping of

condensed water onto the pumping unit (especially cables and electronic parts).

• Ensure that the coolant outlet pipeline is always free and that it cannot get

blocked.

• Install coolant valves always in the supply line of the waste vapour condenser

only.

During operation

•

Maximum ambient temperature: 40 °C

• Make sure ventilation is adequate especially if the pump is installed in a housing

or if the ambient temperature is elevated.

•

Potentially dangerous gases or vapours at the outlet of the pump have to be

drained and disposed of appropriately.

• Due to the high compression ratio of the pumps, the pressure at the outlet port

might get higher than the maximally permitted pressure compatible with the

me-

chanical stability of the system. Ensure that the pump outlet is neither blocked

nor restricted.

If the pump is installed in altitudes of more than 1000 m above mean sea level check

compatibility with applicable safety requirements, especially IEC 60034 (motor might

overheat due to insufficient cooling).

Do not start the pump if the

pressure at outlet port exceeds maximum 1.1 bar

(absolute). Attempts to start the pump at higher pressures may cause blockade and

damage of the motor.

Check compatibility with

maximally permitted pressure at inlet and outlet.

Prevent internal condensation, transfer of liquids or dust. The diaphragms and valves

will be damaged, if liquids are pumped in significant amounts.

Check the pump regularly for external soiling and deposits, clean if necessary to

avoid an increase of the pump‘s operating temperature.

NOTICE

Exhaust waste vapour condenser:

➨

Assemble hose nozzles for coolant inlet and coolant outlet

pipelines at the exhaust waste vapour condenser.

The exhaust waste vapour condenser enables an efficient

condensation of the pumped vapours at the outlet.

☞

No backflow of condensates.

☞

Controlled recovery of condensates.

☞

Next to 100% solvent recovery.

☞

The isolation cover protects against glass splinters in case

of breaking, acts as thermal isolation to avoid condensa-

tion of humidity and is intended to absorb shocks.

PC 301x VARIO

15

16

8