VACUUBRAND PC 3012 VARIO User Manual

Page 53

Documents are only to be used and distributed completely and unchanged. It is strictly the users’ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999164 / 19/05/2009

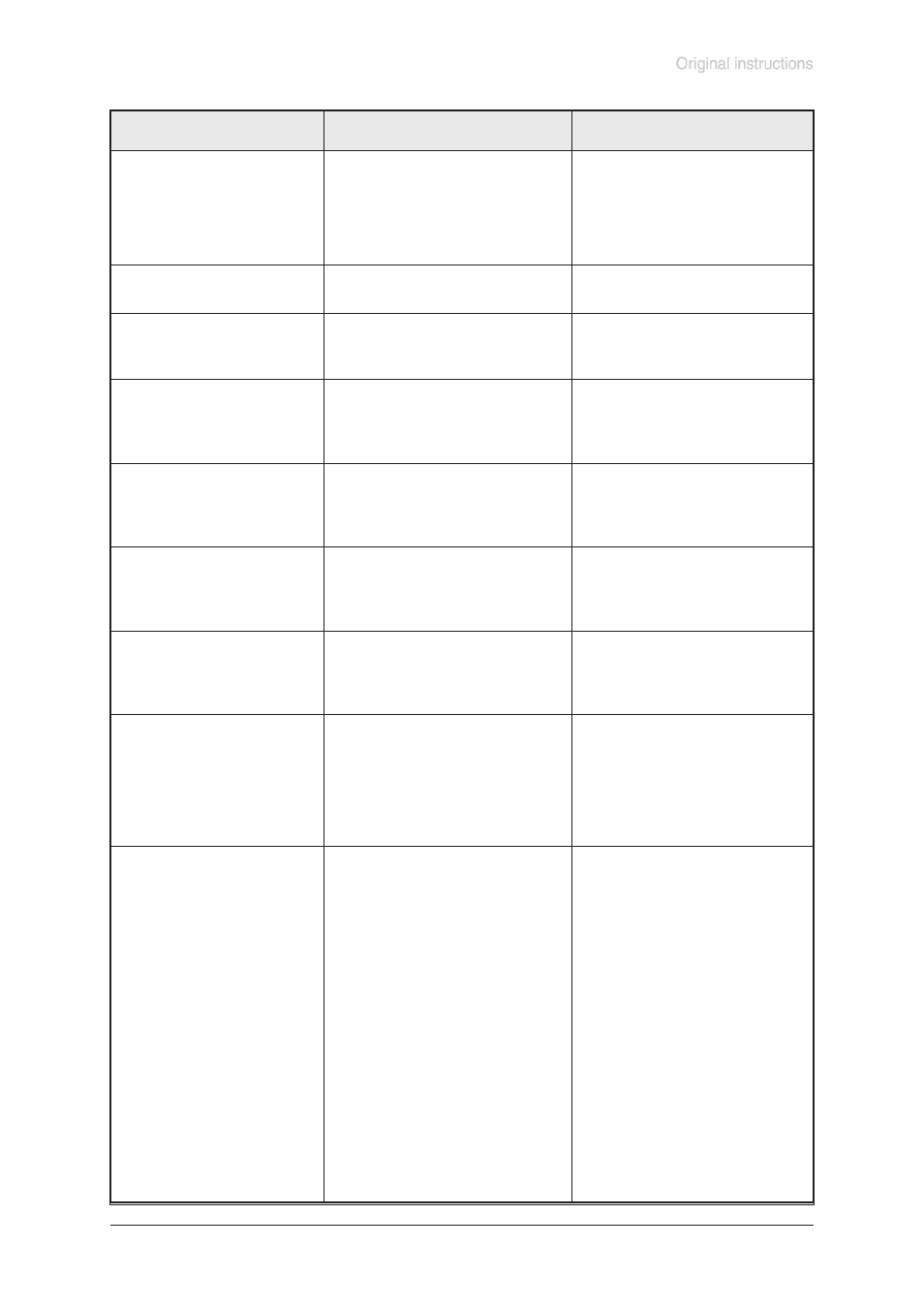

Fault

Possible cause

Remedy

❑ Warning triangle and

pump symbol are flash-

ing, six blips*.

➨ NT VARIO / VARIO-B pump

and VMS** (Vacuum Manage-

ment System) connected?

✔ Remove VMS. Restart con-

troller.

➨ Fault at the NT VARIO /

VARIO-B pump?

✔ Check pump, restart control-

ler.

❑ Clock symbol is flashing. ➨ Preselected process time is

over?

✔ Confirm by pressing key

START/STOP.

❑ Venting valve does not

respond, valve symbol is

displayed.

➨ Venting valve contaminated? ✔ Clean valve.

❑ Operation mode ”Vac

control”: Control stops,

”arrow up” is flashing.

➨ Preset maximum pressure

exceeded?

✔ Confirm by pressing key

START/STOP. Adapt maxi-

mum pressure value if nec-

essary.

❑ Operation mode ”Pump

down”: Control stops, ”ar-

row down” is flashing.

➨ Pressure below preset mini-

mum pressure?

✔ Confirm by pressing key

START/STOP. Adapt mini-

mum pressure value if nec-

essary.

❑ Controller does not

respond when pressing

keys (except ON/OFF).

PC symbol is displayed.

➨ Controller in remote mode?

✔ Control CVC 3000 via in-

terface or switch off remote

mode.

❑ Controller does not

respond when operat-

ing any keys. No change

after switching off/on.

✔ Contact local distributor.

❑ Pump does not start or

stops immediately. Warn-

ing triangle and pump

symbol are flashing.

➨ Pump has been exposed to

condensate?

✔ Allow pump to run for some

minutes at maximum speed

with atmospheric pressure at

the inlet.

➨ Overpressure in the exhaust

line?

✔ Open exhaust line, ensure a

free (pressureless) outlet line.

❑ Pump does not achieve

ultimate vacuum or nor-

mal pumping speed.

➨ Wrong setting at controller?

✔ Select operation mode ”Pump

down” with speed set to ”HI”

and check again.

➨ Centring ring not correctly po-

sitioned or leak in the pipeline

or vacuum system?

✔ Check pump directly - con-

nect CVC 3000 directly at

pump inlet - then check con-

nection, pipeline and vacuum

system if necessary.

➨ Long, narrow line?

✔ Use lines with larger di-

ameter, length as short as

possible.

➨ Pump has been exposed to

condensate?

✔ Allow pump to run for some

minutes at maximum speed

with atmospheric pressure at

the inlet.

➨ Deposits have been formed

inside the pump?

✔ Clean and inspect the pump

heads.