Do steps 51 - 62 if installing ailerons – Top Flite Sierra 40 Trainer Kit User Manual

Page 22

22

48. Test the fit of the die-cut 1 /8" plywood R-

1 B's (1 B) against the R-1 A's. Trim the Ft-1 B's

if necessary for a good fit. The dowel may also

need to be flattened slightly with a sanding block

to allow the R-1 B's a good fit.

49. Glue in the R-1 B's with 15-minute epoxy.

50. For rubber band on wings, glue the die-cut

1/8" plywood R-1 B's to the R-1 A's, forward center

brace (F), and dihedral brace with epoxy.

DO STEPS 51 - 62 IF

INSTALLING AILERONS

51. Cut out and remove the remaining

piece of balsa from across the servo bay in the

bottom side of R-1 C using a knife or razor saw

(see photo at top of next column).

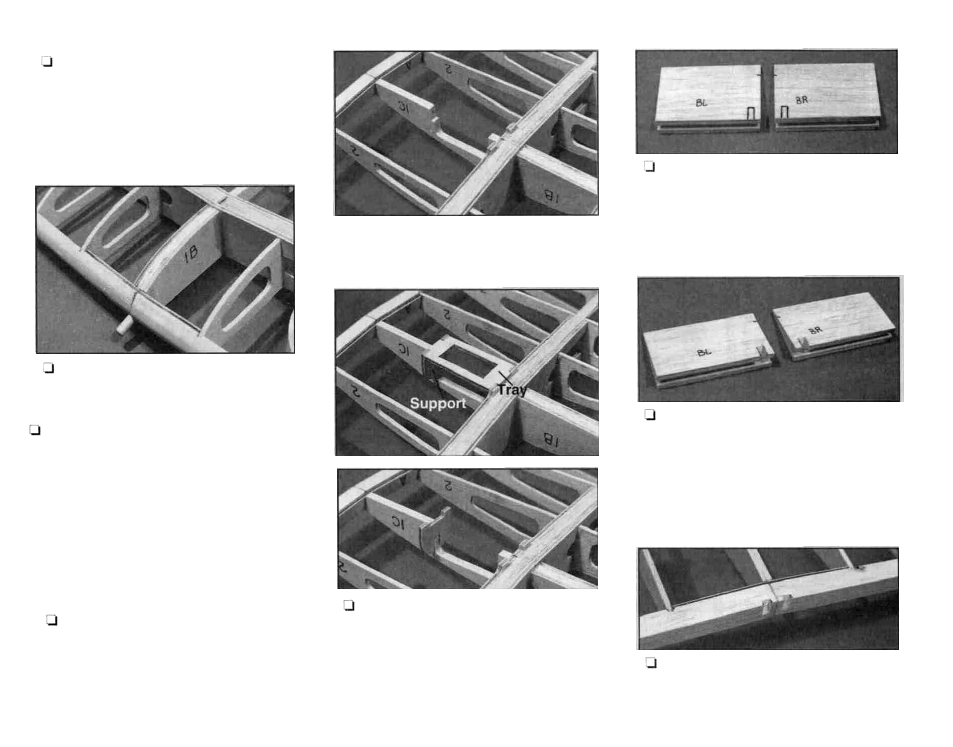

Photo for Step 51

52. Snap the die-cut 1/8" plywood aileron

servo tray and servo tray support in place as

in the photo. Use medium CA to glue in the

servo tray support while using the servo tray to

hold it in position. Do not glue the servo tray in

at this time.

53. Sand the root ends of the tapered and

grooved balsa trailing edge center pieces so

they will meet properly when they are held

together against the TE. Mark the parts so you

can identify the bottom of the left and right parts.

54. Hold the trailing edge center pieces over

the right wing panel plan. Mark where the

torque rods will exit the bottom of the trailing

edge. The root cross-section gives a view of the

cut-out. Cut a notch in the trailing edge center

pieces to allow the torque rod to exit.

55. Hold the trailing edge center pieces up

to the wing. Transfer the notch locations onto