Top Flite TOPA0950 User Manual

Page 17

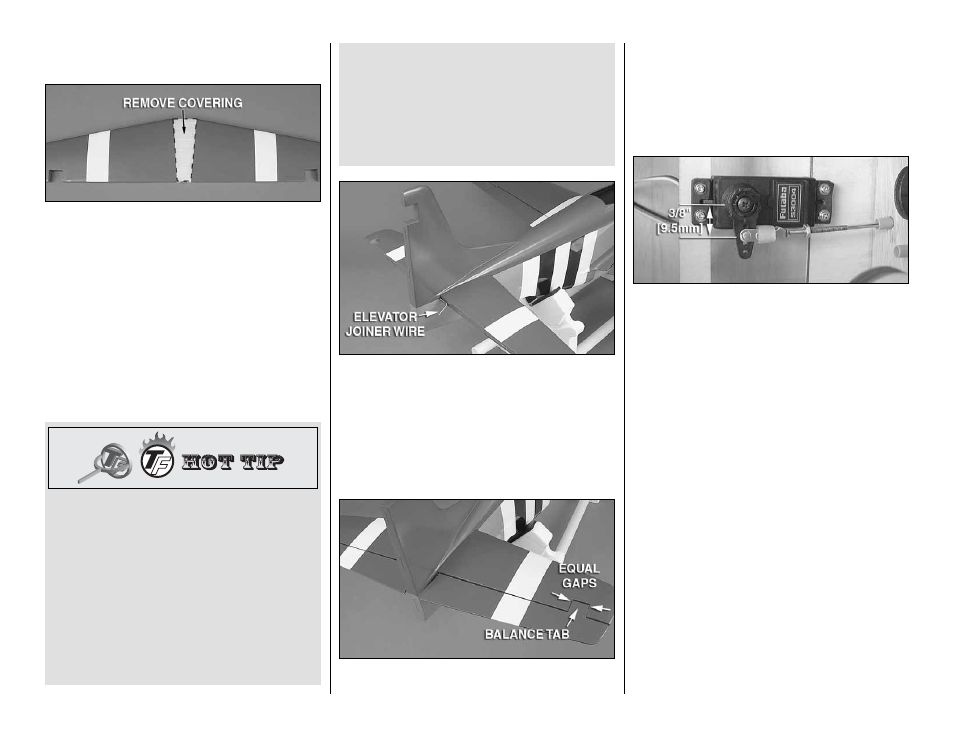

position of the stab, use a felt tip marker to mark the

outline of the fuselage onto the top and bottom of it.

❏

5. Remove the elevators and horizontal stab from

the fuselage. Remove the covering from both sides

of the stab 1/16" [1.6mm] inside the lines you drew.

Wipe away the lines with denatured alcohol.

❏

6. Unhook the clevises from the servo arm and

elevator control horn. Remove the pushrod from the

fuselage. Cut the pushrod to length and solder the

clevis onto the cut end using your mark as a guide.

Install a silicone clevis retainer onto the solder clevis.

Remove the threaded clevis and 2-56 nut from the

other end of the pushrod and insert the threaded end

of the pushrod through the aft end of the elevator

pushrod tube up to the elevator servo.

How To Solder The Clevis To The Pushrod

1. Where the pushrod will make contact with the solder

clevis, roughen the wire with 220-grit sandpaper.

2. Use denatured alcohol to remove any oil residue

from the pushrod wire.

3. Apply a couple of drops of fl ux to the wire. Slide

the solder clevis onto the wire. Using a small

torch or soldering iron, heat the wire allowing

the heated wire to heat the solder clevis. Apply

a small amount of solder to the joint. When the

wire and the clevis are hot enough the solder will

fl ow into the joint. Avoid using too much solder

causing solder to fl ow out of the joint and clump.

Use just enough solder to make a good joint.

Allow the wire and clevis to cool.

4. Put a couple of drops of oil onto a rag and wipe the

joint. This will prevent rust from forming on the joint.

❏

7. Being sure that the elevator joiner rod is still in

position in the stab saddle, use 30-minute epoxy to

glue the stab into the fuselage being sure the stab is

correctly positioned in the stab saddle. Wipe away any

excess epoxy with denatured alcohol and let the epoxy

cure undisturbed.

IMPORTANT: Make sure you reinstall the elevator

pushrod, see step 6.

❏

8. Roughen the ends of the elevator joiner rod and

clean them with alcohol. Insert CA hinges into the

elevator hinge slots. Apply a light coating of epoxy to

the ends of the joiner rod and join the elevators to the

stab with the hinges. Be sure that the balance tabs

on the elevators are centered in the cutouts. When

satisfi ed, apply thin CA to the top and bottom of each

hinge to secure the elevators in place. Wipe away any

excess epoxy from around the joiner rod.

❏

9. Connect the solder clevis to the outer hole in the

elevator control horn of the elevator joiner wire and

slide the silicone clevis retainer to the end of the clevis.

Thread a 2-56 nut and threaded clevis back onto the

pushrod along with a silicone clevis retainer. Make

any adjustments necessary to the clevis so that the

elevators are in the neutral position when the servo

arm is perpendicular to the servo case. When satisfi ed,

attach the clevis to the second hole from the center of

the servo arm, tighten the 2-56 nut against the back of

the clevis with threadlocking compound, and slide the

silicone clevis retainer to the end of the clevis.

17