Top Flite TOPA0708 User Manual

Page 7

7

ASSEMBLE THE WINGS

Start with the left wing so the assembly matches the

photos the fi rst time through.

❏

1. Lay a few paper towels on top of each other and cut

them into small squares. These paper towel squares will

come in handy for wiping away excess epoxy throughout

the assembly process (and will save you from wasting

whole paper towels).

❏

2. If necessary, use a covering iron with a covering

sock to go over the wing, fl ap and aileron to remove

any wrinkles. The best method to remove the wrinkles

is to glide the iron over the covering until the wrinkles

disappear, then go over the area again, pushing down on

the iron to bond the covering to the wood. If the wrinkles

don’t disappear, the balsa in that area might be fl exing

inward. If this is happening, don’t press down. Simply let

the heat of the iron shrink the covering. If the wrinkles

momentarily disappear, then immediately reappear, the

iron may be too hot, thus causing air bubbles. Lower

the temperature of the iron or use a sharp #11 blade

to puncture several holes in the covering, then reheat.

The suggested iron temperature is around 360

˚

F.

MOUNT THE AILERON SERVOS

❏

❏

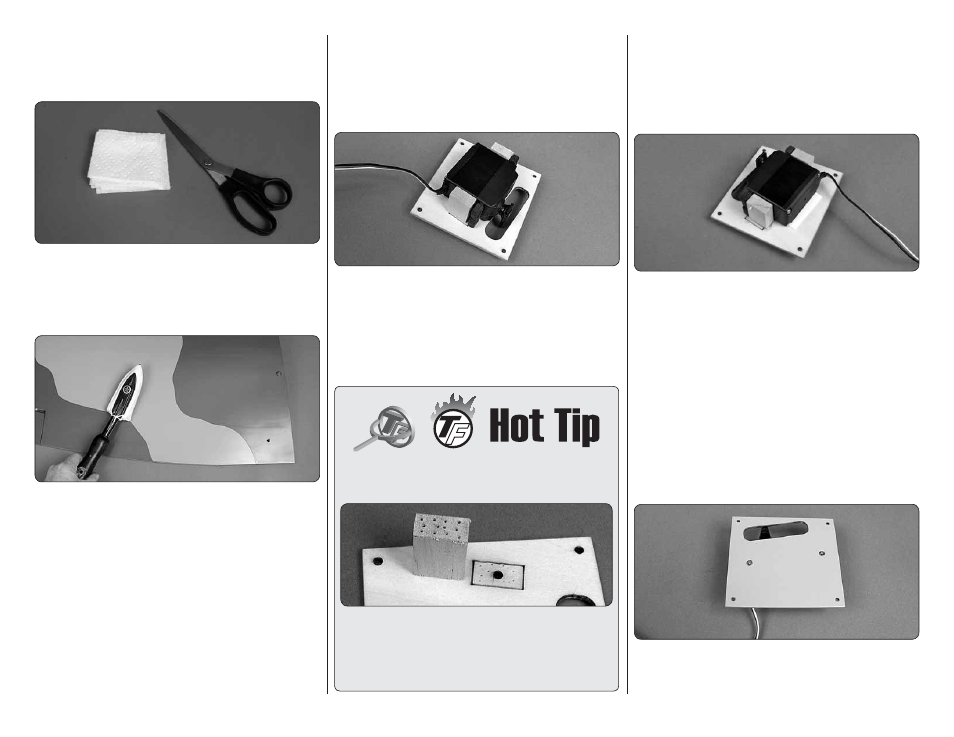

1. Carefully remove the left aileron servo hatch

from the wing by peeling off the masking tape holding

hatch to the wing. Use a paper towel square dampened

with naphtha lighter fl uid or similar solvent to remove

any glue left behind from the tape.

❏

❏

2. Install the rubber bushings and metal grommets

in the aileron servo. Install a servo arm on the aileron

servo. Position the aileron servo on the aileron servo

hatch cover as shown. Set the two 9/16" x 3/4" x 3/8"

[15 x 20 x 8mm] hardwood blocks over the embossed

servo block locations to check that the block locations

are correct. If not, mark the new locations.

When mounting the servo blocks on the bottom of the

servo hatch, make sure that the grain of the wood is

perpendicular to the hatch.

To increase the strength of the glue joint, use a T-pin

to prick holes into the gluing surface of the servo

blocks and the plywood servo hatch. Be careful not

to prick holes completely through the servo hatch

and covering.

❏

❏

3. Use 6-minute epoxy to glue the two blocks to

the bottom of the servo hatch over the embossed servo

block locations. Thoroughly coat the end of the blocks

and allow them to set for a few seconds to allow the

blocks to absorb the epoxy, then recoat the blocks. Use

clamps to hold the blocks to the servo hatch.

❏

❏

4. Once the epoxy has cured, remove the clamps.

Place a 1/16" [1.6mm] spacer, such as a piece of

cardstock from the header card of the servo extension

or a piece of paper folded several time, under the servo

and between each mounting block. After the servo is

installed the spacer will be removed, providing adequate

spacing for vibration isolation.

❏

❏

5. Drill 1/16" [1.6mm] holes through the blocks

for the servo mounting screws. Mount the servo to

the blocks with the screws that came with the servo.

Remove the servo mounting screws and apply a couple

of drops of thin CA in each hole to harden the threads.

Allow the CA to fully harden. Then, reinstall the servos

and remove the spacer.

❏

❏

6. Drill 1/16" [1.6mm] holes through the blocks at

the two hole locations on the top of the hatch. Install

two #2 x 3/8" [9.5mm] fl at head sheet metal screws to