Top Flite TOPA0708 User Manual

Page 11

11

with a 5/32 [4mm] drill bit. Secure the landing gear

cover to the retract with two 6-32 x 1/4" machine screws

and #6 fl at washers. Note that clear plastic shims have

been provided to raise the landing gear cover so that it

is fl ush with the bottom of the wing if needed.

❏

12. Return to step 1 and mount the right retract in

the right wing.

JOIN THE WING

Note: Keep the retracts in the retracted (up) position so

they do not extend and retract as you handle the wing.

❏

1. Use 6-minute epoxy to glue the two 5/16 x 1-5/8"

[8 x 41mm] wing alignment dowels into the root of the

left wing half.

❏

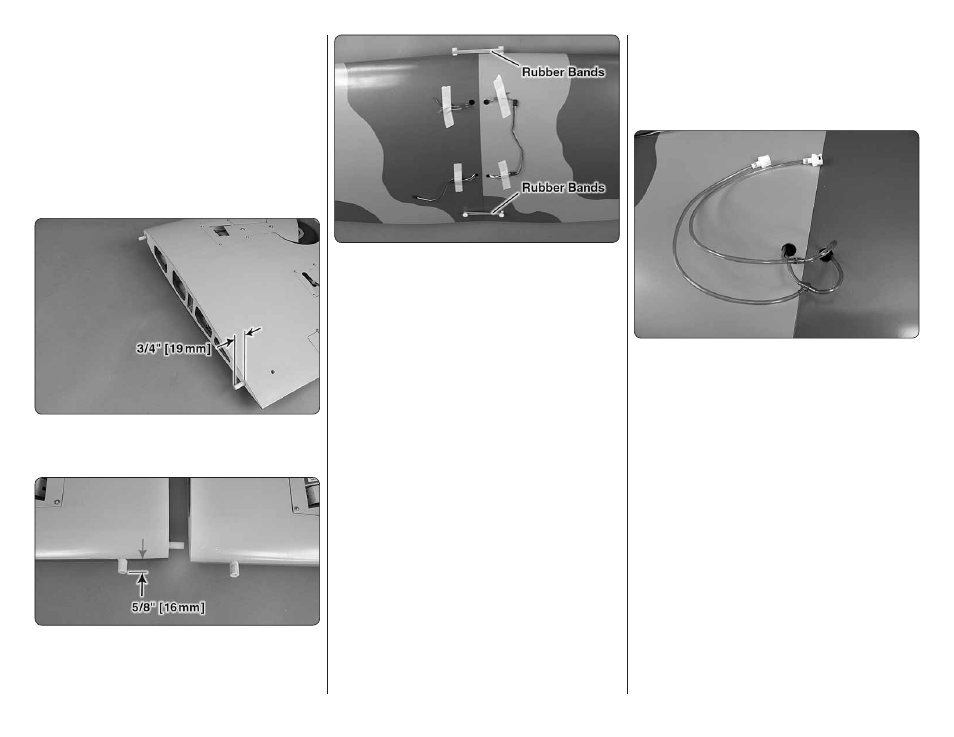

2. Use 6-minute epoxy to glue the two 3/8 x 1-3/4" [9.5

x 44mm] diameter forward wing dowels in the leading

edge of both wing halves. The wing dowels should

protrude approximately 5/8" [16mm] from the wing.

❏

3. Test fi t the hardwood wing joiner in each wing

half, making sure that both wing halves fi t together at

the root without any gaps. Trial fi t clamping the wing

together with rubber bands around the wing dowels

at the leading edge. Insert the two ¼ - 20 x 2" [51mm]

nylon wing bolts and stretch rubber bands around the

wing bolts on the top and bottom of the wing.

❏

4. Read through the next three steps before

mixing any epoxy. Gather everything required for gluing

the wing together including 30-minute epoxy, mixing

sticks, epoxy brushes, 12" [305mm] long dowel or wire,

denatured alcohol and paper towels. Remove the rubber

bands and separate the wing halves. Remove the wing

joiner. Mix 2 oz. [59.1cc] of 30-minute epoxy. Working

quickly, pour a generous amount into the joiner pocket

of one wing half. Use your wire or dowel to thoroughly

distribute the epoxy, coating all surfaces inside the joiner

pocket. Coat the root rib and one half of the wing joiner

that goes into the wing. Insert the joiner in the wing.

❏

5. Coat the joiner pocket of the other wing half and

the other end of the wing joiner. Join the wing halves

together. Then, stand the wing on end with one of the

wing tips resting on the fl oor. Use a piece of R/C foam

or something similar to cushion and stabilize the wing

so it won’t slide around.

❏

6. With the wing resting on end, use a paper towel

dampened with denatured alcohol to wipe off any excess

epoxy as it squeezes out. Wrap the rubber bands around

the wing dowels and wing bolts. Add several strips of

masking tape to tightly hold the wings together as you

continue to wipe off excess epoxy as it squeezes out.

Be certain the leading edge and trailing edges of the

wing accurately align. Do not disturb the wing until the

epoxy has fully cured.

❏

7. Join the matching air lines from each wing half

with a couple of T-fi ttings that came with the air control

kit. Cut two 10" [250mm] pieces of corresponding color

air line (also from the control kit) and fi t each line to the

T-fi ttings. Connect one quick-connector with an O-ring

to one of the air lines and one of the quick connectors

without an O-ring to the other line. This will prevent

improper connection to the quick-connectors on the air

valve when mounting the wing to the fuselage.

❏

8. Connect both servo wires from the aileron servos

to a Y-harness and both servo wires from the fl ap servos

to a Y-harness.